Charles R. Goulding, Jacob Nolan and Preeti Sulibhavi examine recent investments and breakthroughs in hydrogen engine technology.

As part of the Inflation Reduction Act (IRA), the U.S. federal government is funding US$7 billion for hydrogen projects.

The racecar industry is often the forerunner for commercial applications of developing technology.

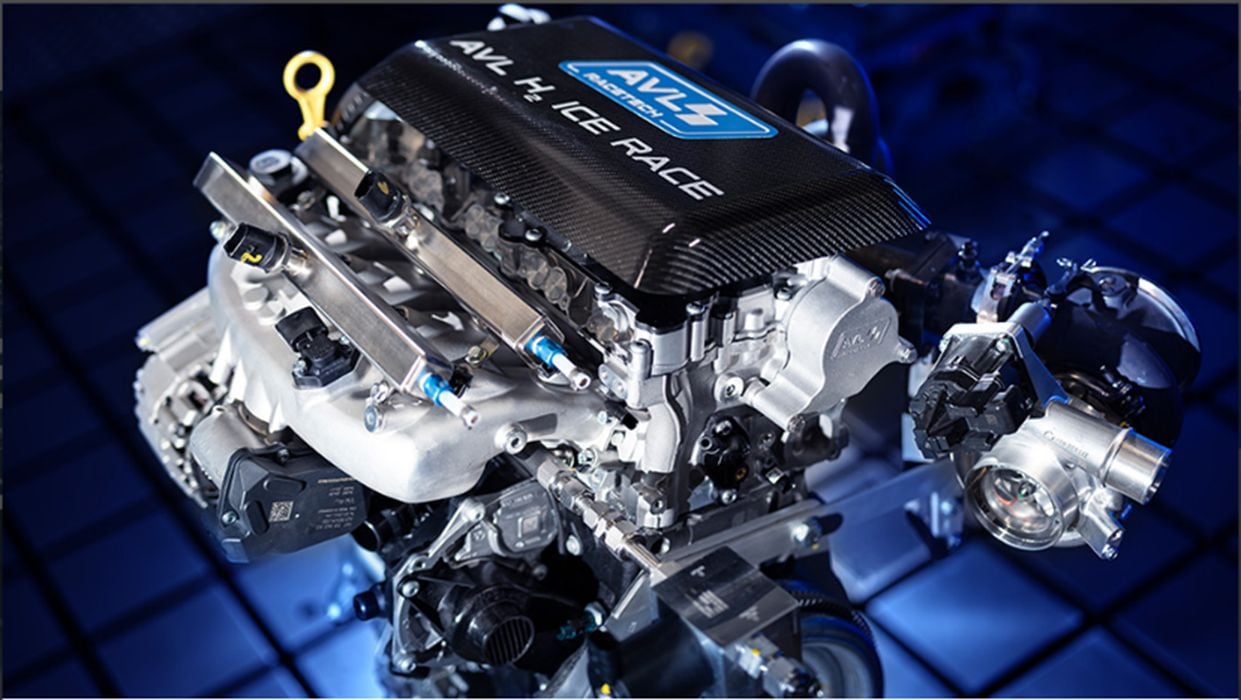

This is why the Austrian automotive supplier AVL’s achievement of a hydrogen engine for race cars is important.

For those not as familiar with this technology, a hydrogen internal combustion engine (H2ICE) vehicle is a type of hydrogen vehicle using an internal combustion engine. Hydrogen internal combustion engine vehicles are different from hydrogen fuel cell vehicles which utilize hydrogen electrochemically rather than through combustion. Instead, the hydrogen internal combustion engine is simply a modified version of the traditional gasoline-powered internal combustion engine. The absence of carbon means that no CO2 is produced, which eliminates the main greenhouse gas emission of a conventional petroleum engine.

This is one alternative to an electric-powered vehicle, especially for vehicles meant for high speed.

AVL RaceTech

Unlike other H2 internal combustion engines, which are usually operated with a high level of excess air, meaning they generate comparatively less performance, AVL RACETECH’s new racing engine with only a slight lean-burn can generate a performance level of around 150 kW per liter. To achieve this high specific performance, AVL RACETECH transferred the principle of water injection to the hydrogen engine. An injector shoots additional water into the intake air of the engine, which increases the boost pressure. This is a literal game-changer for the race car industry.

The hydrogen engine was developed in cooperation with HUMDA Lab. In 2023, HUMDA became the first subsidiary of Szechenyi Istvan University Foundation, the managing authority of the University of Gyor, Hungary. HUMDA is headquartered in Budapest, Hungary and its engineers and researchers have a strong passion for racing.

Balaton Park in Hungary

The Balaton Park Circuit was officially opened in Balatonfőkajár in May 2023. Except for hosting Formula One and MotoGP races, the facility can accommodate any motorsport event. The 4115-meter-long asphalt track with 16 curves is located a few kilometers from the M7 motorway and only 85 kilometers away from Budapest and is complete with a wide range of supporting facilities.

The main phase of construction for Balaton Park started in 2019. The racetrack is owned by a private group of investors led by former racecar driver Chanoch Nissany. The circuit is intended to be a modern addition to Hungary’s motor racing scene, complementing the older and well-established Hungarian circuit. The track features Tecpro barriers and ‘MyLaps’ latest technology, including GPS, LED panels and timing systems.

Going Places with Toyota

The ability to leverage existing internal combustion engine technologies is key. Quick refueling times. A significant reduction in the need for limited supply elements like lithium and nickel. Toyota believes that hydrogen combustion could lead to widespread, accessible carbon-reduction solutions faster than any other method at this time.

The IRA Funds Hydrogen Technology

As part of President Biden’s Investing in America agenda, a key pillar of Bidenomics, the U.S. Department of Energy (DOE) announced in the fourth quarter of 2023, $7 billion to launch seven Regional Clean Hydrogen Hubs (H2Hubs) across the nation and accelerate the commercial-scale deployment of low-cost, clean hydrogen—a valuable energy product that can be produced with zero or near-zero carbon emissions and is crucial to meeting the President’s climate and energy security goals.

Funded by President Biden’s Bipartisan Infrastructure Law, the seven H2Hubs will kickstart a national network of clean hydrogen producers, consumers, and connective infrastructure while supporting the production, storage, delivery, and end-use of clean hydrogen. The H2Hubs are expected to collectively produce three million metric tons of hydrogen annually, reaching nearly a third of the 2030 U.S. production target and lowering emissions from hard-to-decarbonize industrial sectors that represent 30 percent of total U.S. carbon emissions. Together, they will also reduce 25 million metric tons of carbon dioxide (CO2) emissions from end-uses each year—an amount roughly equivalent to the combined annual emissions of 5.5 million gasoline-powered cars—and create and retain tens of thousands of good-paying jobs across the country while supporting healthier communities.

This is one of the largest investments in clean manufacturing and jobs in history. This transformative Federal investment will be matched by recipients to leverage a total of nearly $50 billion to strengthen local economies, create and maintain high-quality jobs—especially those that support worker organizing and collective bargaining—and slash harmful emissions that jeopardize public health and pollute local ecosystems. In addition to positioning America to be a global leader in emerging clean energy industries, the H2Hubs will implement comprehensive local benefits and workforce proposals to support an equitable and inclusive clean energy future.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Credits.

And the Winner Is…

Start your engines because 3D printing has entered the fast lane and there is no sign of stopping. With the development of the carbon-free engine for racecars, Formula 1 may be headed for greener pastures.