How additive manufacturing can play a role in the ramping up of marine energy systems.

Marine energy is a promising segment within the renewable energy industry, that harnesses kinetic energy from natural phenomena like water currents and tides and converts it in clean energy that can power local coastal communities. According to the U.S. Office of Energy Efficiency and Renewable Energy, marine energy resources could reach 57% of all power generated by the U.S. in 2019. In other words: there is incredible potential and there are many innovative projects underway that aim to advance the exploitation of this renewable resource.

One such project is being led by researchers at the National Renewable Energy Laboratory (NREL) in partnership with the Pacific Northwest National Laboratory. Together, they have been investigating how additive manufacturing can be used to enhance marine energy technologies with a particular focus on tidal power generation, which uses turbine technologies to convert the energy from tidal waters into power we can use.

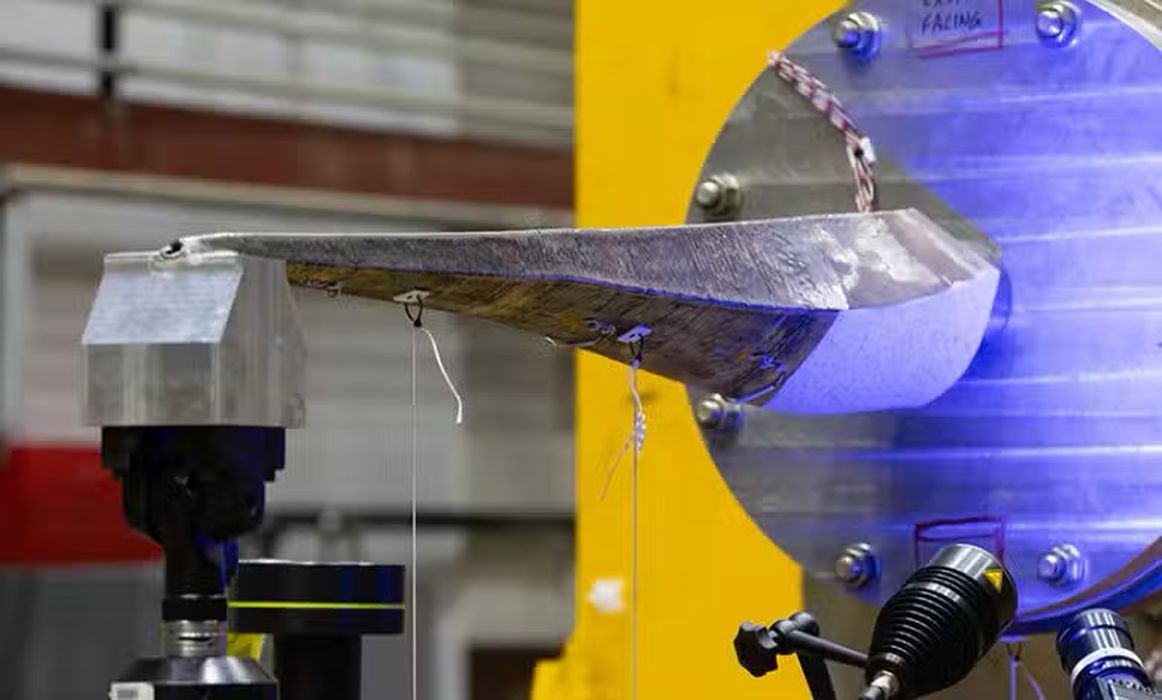

Over the past two years, the project has been testing and analyzing various materials and printing technologies in the development and production of tidal turbine spars. Turbine spars are load-bearing parts within a turbine assembly that hold the turbine blade in place. Not only must the component be able to support the turbine structure, it must also withstand the corrosive forces of the ocean environment. After some evaluation, thermoplastic 3D printing was found not suitable for this specific application; the best candidates for producing tidal turbine spars were stainless steel and laser metal deposition.

“We’ve opened a really unique design space through 3D printing,” said Paul Murdy, a mechanical engineer at NREL and principal investigator for the marine energy AM study. “This project has demonstrated that additive manufacturing has the potential to produce very strong, stiff structures that will be good for marine energy.”

The 3D printed turbine spar the NREL team has been developing is designed to fit in with existing tidal tubine systems. This, the researchers say, could facilitate the rapid prototyping of new marine energy devices for various blue economy sectors including aquaculture and microgrids, which could power coastal communities. Down the line, it would also make it easier for coastal towns and communities to replace worn components in their marine energy systems by printing parts locally, leading to less reliance on supply chains.

Miguel González-Montijo, a graduate intern at NREL who designed the part, said: “For specific communities in particular places, marine energy could be a game changer. For example, my home, Puerto Rico, could benefit from an upgraded energy grid that incorporates renewable energy technologies like marine hydrokinetic energy. These technologies could help many small towns build energy resilience and independence while delivering locally sourced, renewable power.”

Read the rest of this story at VoxelMatters