Hyperganic announced a new and very speedy 3D simulation technology.

Hyperganic is a German startup focusing on new ways to create 3D designs. They call their approach “algorithmic engineering”, because they make heavy use of AI techniques to generate structures in ways that humans could never do.

In fact, one of their most notable accomplishments was designing what could very well be the most complex item ever 3D printed: an aerospike rocket engine, which we reviewed earlier.

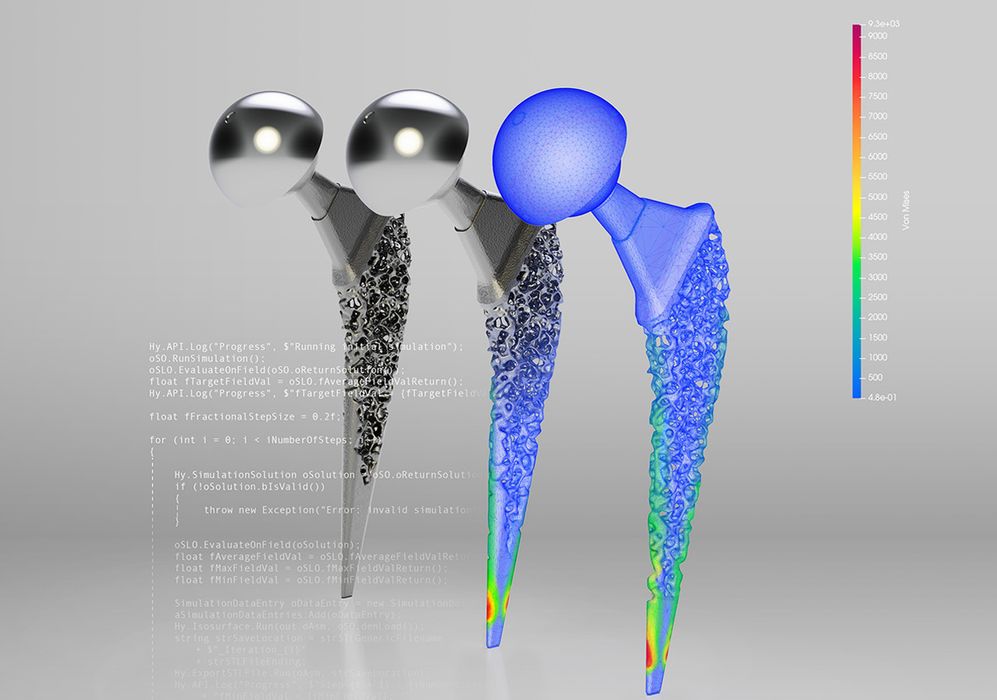

But generating a 3D design is only part of the problem. Designers also need to perform simulations on the design iterations to ensure it performs in the intended fashion. This is particularly important for production parts, especially those that are used in critical applications.

Simulation is not new; it’s been around for years and is most frequently done in an “offline” manner. The amount of computation required to do a simulation almost always requires minutes, hours or even days to complete. It’s the kind of thing you tend to “let run overnight” and pick it up in the morning. While processing hardware has become faster in recent years, that hasn’t really sped things up because more simulations are done in finer detail.

Enter Hyperganic, who now say they have a much faster solution that leverages their AI platform. They explain:

“Unlike conventional simulation software, Hyperganic’s technology is up to 80% faster and features a built-in framework that allows users to simulate objects directly within the workflow without having to set the parameters. This automated workflow enables engineers and researchers to instantly evaluate and test Algorithmically Engineered objects as complex as nature and improve them in a process of digital evolution until an optimal design is attained.”

To achieve this they are using a newly developed meshing process. They said:

“Hyperganic overcomes that challenge by using the Finite Cell Method developed at the Technical University of Munich and commercialized by DirectFEM, which the company acquired in April 2022. This method saves time and improves efficiency by allowing the instantaneous physical simulation of complex designs without any manual interaction.”

The speed increase is so dramatic that designers might even be able to see the results of the simulation while still at their workstation. This could significantly change the workflow of designers, as the “overnight wait” might become a thing of the past.

The result should be better parts designed more quickly. A side effect will also be increased demand for 3D printing services, as this software will no doubt create many more incredibly complex parts that can be manufactured only with additive technologies.

Hyperganic has bundled the new tech into their system, Hyperganic Core. They say it will be available free of charge for a limited time, after which there will be a charge for use. It’s not clear whether this will be subscription fee or one time charge.

Via Hyperganic