There’s many applications of 3D printing, but perhaps none more important than those that help solve the climate emergency.

Enter the science of Electrolysis, the process by which water is split into hydrogen and oxygen molecules. The separated hydrogen can then be used as fuel in new applications, where water is formed from the combustion process as it recombines with oxygen.

You’ve probably done this experiment in high school where you stick two electrodes in some salty water and watch tiny bubbles form on each. One would be hydrogen, the other oxygen.

But that is an incredibly inefficient method of electrolysis. There are more effective methods that use different metals as catalysts to greatly improve the efficiency. That efficiency is key to adoption of the technology over fossil fuels, but only if offers a better cost benefit ratio.

Thus there is a great deal of research taking place trying to identify the most effective method of performing electrolysis.

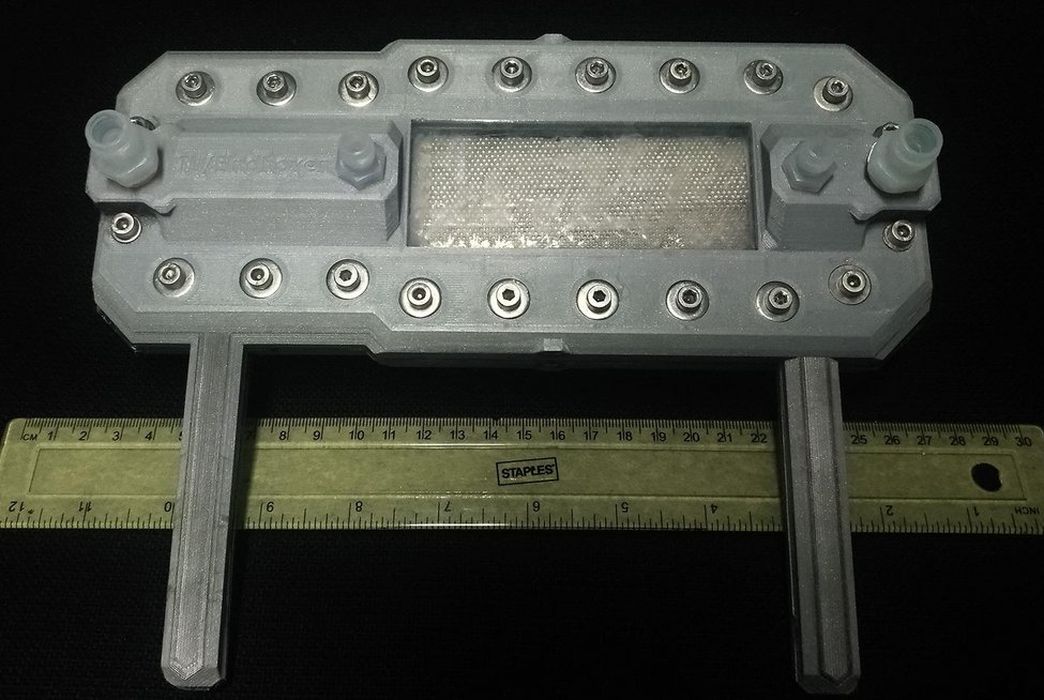

One researcher, Stephane Weusten of the Eindhoven Institute of Technology, is using 3D printing to assist this important research.

According to a report from TU/e, Weusten has been using iterative design to hone in on an optimal electrolysis design. They explain:

“ But step by step, Stephane Weusten did manage to improve performance by adjusting the geometry of the electrolyzer. For example, the researcher changed the shape of the inlet so that the molecules collided faster and the higher reaction rate produced more hydrogen in a shorter time. He also modified the 3D electrodes. In total, all the modifications resulted in a seven times higher reaction rate.”

That “seven times” is critically important. It literally means that this approach has a seven times better financial ratio. That gives this green technology a far better chance of succeeding in the market.

This rapid approach to prototyping has been available for, well, decades. But even so it is still new to many, as this report indicates.

My hope is that 3D printing becomes much more well understood by the general population so that projects of this type would be entirely natural and completely unworthy of reporting.

We’re getting there, but not quite finished yet.

Via TU/e