INTAMSYS launched a new desktop 3D printer that can operate at high temperatures.

The new FUNMAT PRO 310 leverages the company’s previous experience with high temperature 3D printing. Their FUNMAT HT, FUNMAT PRO 410 and FUNMAT PRO 610 all offer high temperature possibilities with a combination of heated build chambers and high-temperature nozzles.

The FUNMAT PRO 310 differs from the rest of the series in that it’s a desktop device, one that visible appears little different from countless other enclosed desktop 3D printers.

However, the differences are seen inside the device.

The FUNMAT PRO 310 includes an actively heated build chamber that can reach 100C, with hot ends that can reach 300C. This combination allows the device to 3D print a wide variety of engineering materials to produce end-use parts. If you haven’t guessed yet, that’s how the machine and series are named: “FUNMAT” is short for “Functional Materials”.

In addition to the high temperature environment, the FUNMAT PRO 310 includes several other very interesting features.

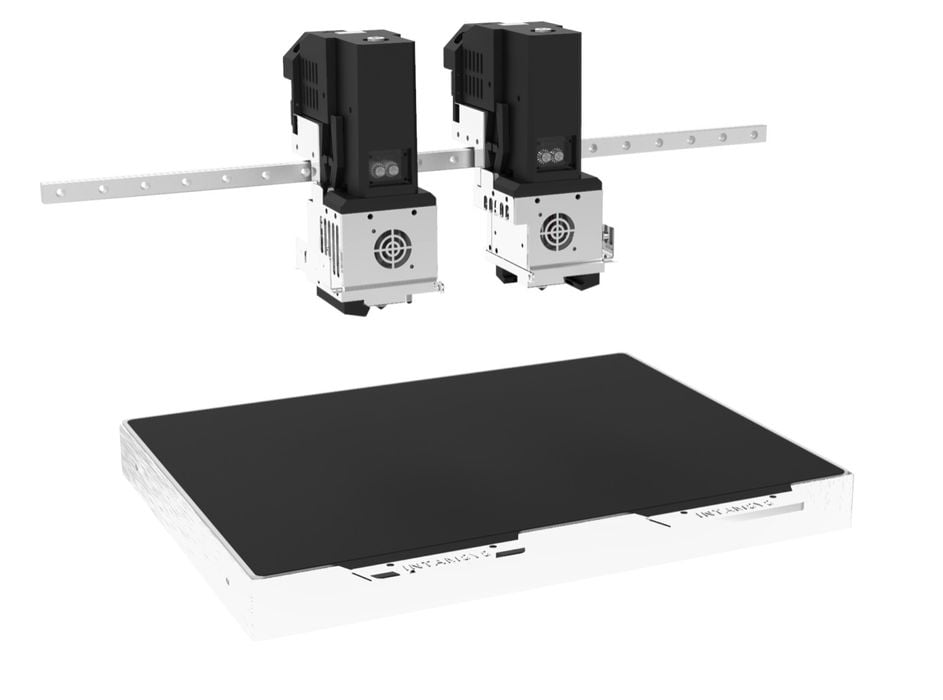

The most notable would be the dual independent extrusion system (IDEX). This allows the device to 3D print two materials in the same job, but normally the second extruder would be used for high temperature soluble support. That enables the production of highly complex geometries that are only possible with copious amounts of soluble support structures.

The build chamber on this desktop machine is in fact a bit smaller than found on the larger devices, at 305 x 260 x 260 mm. However, when using the IDEX system, the build volume shrinks a bit on the X-axis to 260 x 260 x 260 mm. Either way, those build volumes are certainly sufficient for many types of 3D prints.

Note that you shouldn’t use common soluble support materials in this machine at high temperatures, like PVA, because they would melt in the hot chamber. This means you likely should use support materials specifically designed for high temperature environments. INTAMSYS said the FUNMAT PRO 310 is able to use HIPS, PVA, SP3040, and SP3050.

INTAMSYS said the FUNMAT PRO 310 is able to easily handle the most common engineering materials, including PA6/66, PA6-CF, PA12-CF, PC, PC-ABS, ABS, ASA, and PLA.

The extrusion system also includes quick-swappable extruders. This enables a rapid ability to change to enable use of different materials, or to keep the machine running if there’s a filament jam.

The build plate on the FUNMAT PRO 310 is a magnetically attached, coated spring steel plate. This is the de facto standard for desktop FFF devices these days, and it’s good news to see INTAMSYS using it in the FUNMAT PRO 310.

One of the persistent issues that occurs with engineering materials is that they are hygroscopic. If left in the open air, many of them will quickly absorb moisture and this can in turn corrupt subsequent 3D printing: the absorbed water boils when heated in the hot end, creating bubbles and distortions in the extrusion.

The best practice is to keep the filament as dry as possible. Many 3D printer manufacturers have developed or included “dry box” systems to do so, and INTAMSYS has done so with the FUNMAT PRO 310. It’s an external dry box, which they call the “Independent Filament Box”.

It holds a couple of spools and keeps them at very low humidity levels, as monitored with temperature and humidity sensors. The interesting feature is that the box includes a “molecular sieve”, rather than the more common desiccant approach. The molecular sieve can pick off H2O molecules continuously for long periods of time, up to 15 days at 10% humidity, according to INTAMSYS’ video:

Finally, the FUNMAT PRO 310 includes the usual convenience features one would expect on a professional device, including a large color touchscreen for device control, intelligent automated calibration, and motion compensation for increased print quality.

One final point is that INTAMSYS has included a series of API interfaces that could permit the FUNMAT PRO 310 to connect with MES (manufacturing execution systems) for remote control in a factory scenario.

It’s likely INTAMSYS has been receiving requests from customers who liked the functionality of the company’s larger devices, but wanted the same features in a small and less expensive package. INTAMSYS seems to have reacted with this new device to address that market.

Via INTAMSYS