Integrated 3D printed sensors could be coming soon as the result of new research.

Integrated 3D Printed Sensors: A Game Changer

A new era of integrated 3D printed sensors could be on the horizon, thanks to groundbreaking research in piezoelectric circuits. Piezoelectric circuits generate electricity when pressure is applied, making them ideal for creating pressure sensors and operational buttons.

Polymer Materials for Piezoelectric Circuits

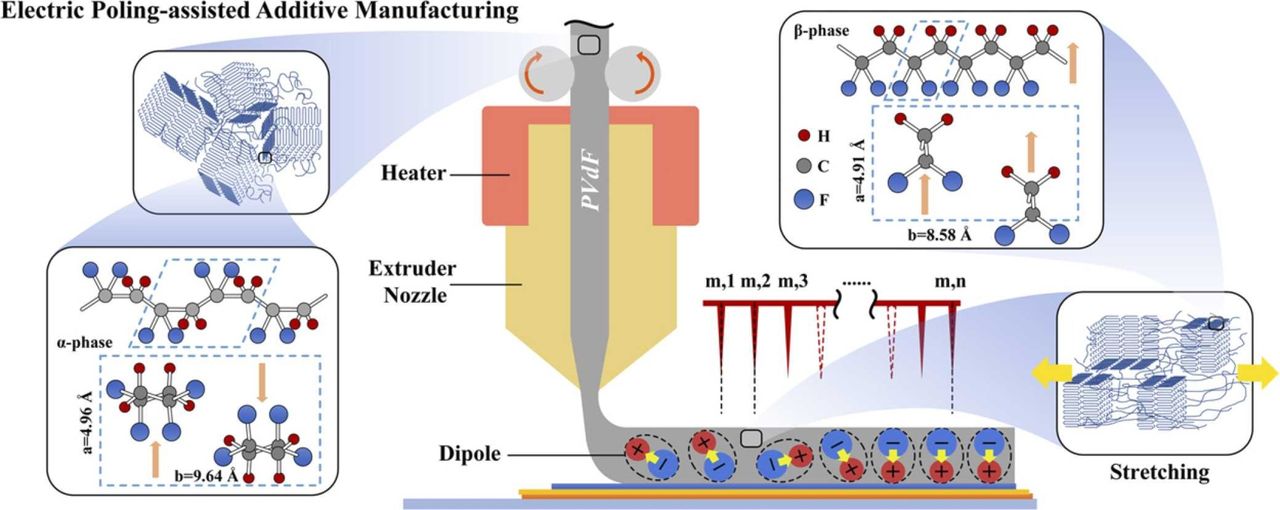

Ceramic piezoelectric materials exist, but polymer materials hold more promise due to their ease of use and capacity for creating unique geometries. However, there’s a challenge: the PVdF materials used to build them are often limited to planar or wire geometries because of the manufacturing processes employed. Moreover, the objects must undergo post-processing treatment with an electric field to align the material’s dipoles.

Electric Poling Additive Manufacturing (EPAM)

Researchers have discovered a solution to these issues through a novel 3D printing process called Electric Poling Additive Manufacturing (EPAM). The EPAM process prints free-form PVdF structures and induces the formation of the β-phase, which is primarily responsible for the piezoelectric response. The process involves stretching the molten PVdF rod, rearranging the amorphous strands in the film plane, and applying an electric field to align the dipoles.

The researchers also found that the 3D printed samples displayed anisotropic mechanical behavior, with the bonding surface strength being sensitive to printing speed. They were able to 3D print a small device using EPAM and successfully demonstrated their ability to 3D print piezoelectric components.

The Future of Active 3D Printed Devices

This exciting development could pave the way for a new world of active 3D printed devices. Imagine a specialized 3D printer equipped with an EPAM printhead alongside standard 3D printheads, capable of printing objects with embedded piezoelectric sensors or buttons directly on their surface. The 3D printing approach allows for non-planar sensors or buttons, opening up possibilities for innovative designs and applications.

Furthermore, this technology offers intriguing potential for energy capture. Piezoelectric circuits could harvest energy from motion and pressure encountered in 3D printed parts, possibly reducing the need for more powerful traditional energy sources.

Via ScienceDirect