3D Systems made a very interesting corporate move this week by acquiring dp polar.

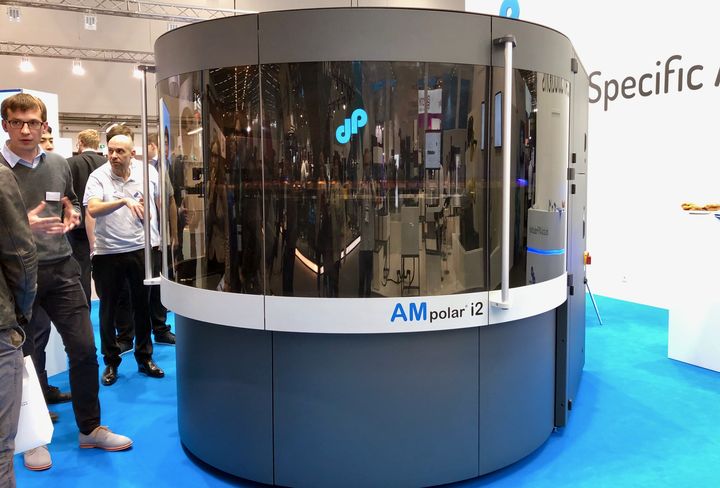

The highly unusual rotating platform process used by dp polar in their AMpolar i2 system might be just what 3D Systems needs.

dp polar is a German startup that created the High Speed Rotative (HSR) process, which is a variation of the material jetting process. It’s quite amazing to see in action, as a massive circular plate spins at great speed. As the plate rotates it comes under the print heads each revolution. The print heads then selectively deposit drops of liquid photopolymer resin, which immediately solidify since the build chamber is lit with UV light.

The circular plate is about 2m across, but offers about one square meter of build area. dp polar said the print volume is about 240l, which is about the equivalent of a 620mm cube — except that here that volume is spread out, allowing for many parts to be made in a single print job.

The speed of the rotation means that the entire plate can be quickly covered with parts, meaning HSR is a technology intended for serial production of 3D printed parts. We took a deeper look at HSR in a previous post.

The news is that the owner of the majority of dp polar, ALTANA, has agreed to sell their stake to industry giant 3D Systems. ALTANA is a specialty chemical company developing AM materials, so it does make sense that they shouldn’t be building 3D printers. I suspect ALTANA began working with dp polar as a way to assist in the development of new AM materials, but this would not be a long term arrangement. ALTANA explains:

“ALTANA had invested in dp polar in 2017. During the partnership, the start-up, based in Eggenstein-Leopoldshafen near Karlsruhe, Germany, had worked closely together with ALTANA to develop the world’s first 3D printing systems with a continuously rotating print platform, the AMpolar machine generation for material jetting.”

Now ALTANA will continue to develop their Cubic Ink material family, but somehow I suspect they will have closer ties with 3D Systems after the smoke clears in this situation.

For dp polar, this is incredibly good news. A small company with amazing technology always has a hard time breaking into markets because most of them are already captured by resellers with arrangements with other providers. By being part of 3D Systems, their equipment will now flow through 3D Systems’ huge worldwide sales and distribution network.

They will also no doubt benefit from use of 3D Systems’ extensive materials library, where additional applications will be enabled on the AMpolar i2.

For 3D Systems, the deal tells us something deep about the company, but to see it you have to step back and look at their history over the past several years.

3D Systems began operations in the 1980s with the invention of the SLA process by founder Chuck Hull. Under patent protection, they were able to transform the company from a startup into one of the industry’s leaders. Along the way they added SLS technology and for many years they were one of the few providers of these technologies.

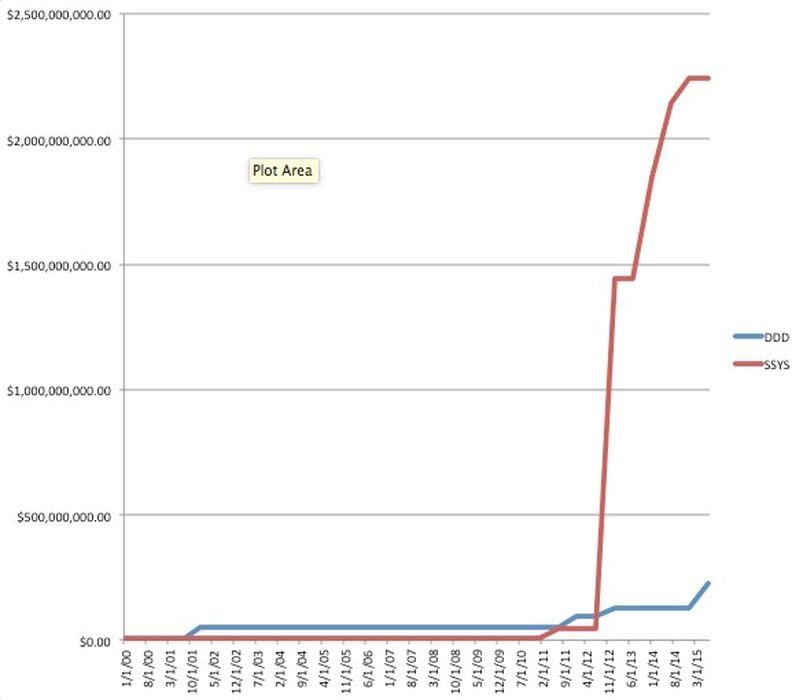

During the 2010-2015 period, 3D Systems went on an acquisition spree, gobbling up dozens of companies (about 54 companies, by our count). One reason for doing so was that they, along with Stratasys, were facing the end of their original patent protection. By acquiring companies with new technology still under patent, their business models could continue.

Stratasys’ big move at the time was to acquire Objet, which gave them the PolyJet technology that they leveraged into great use today. Somehow, the numerous acquisitions of 3D Systems didn’t blossom in a similar manner, and 3D Systems has mostly continued forward with their existing technologies, SLA and SLS.

More recently there has been greatly increased interest in use of 3D printing for serial manufacturing. Several 3D printer manufacturers have begun to address this by designing new or adapting older technologies for this purpose. Sometimes startup companies are acquired to short circuit the effort.

Stratasys’ effort towards manufacturing has involved use of several unusual industrial demonstrators, which seem to have faded away. But then, they acquired Xaar 3D technology, which should be able to produce very high throughput. That technology, known as Selective Absorption Fusion (or “SAF”), has been adapted into their new H350 device.

Meanwhile 3D Systems’ approach to serial manufacturing involved promoting their Figure 4 system, which is essentially a robotically automated SLA configuration. It’s mostly the same SLA 3D printing process, with sophisticated robotics allowing many machines to operate in parallel to achieve higher throughput.

When you compare the approaches used by these two companies, there is a big difference: Stratasys opted for an entirely new technology that inherently is high throughput. 3D Systems instead opted for the more brute force approach of parallel operation.

But now that strategy may have changed with the acquisition of dp polar. Like SAF, HSR offers an entirely new way to achieve high throughput 3D printing that is the core of the technology.

Could it be that 3D Systems is looking for a better way to achieve serial production over their Figure 4 system with the AMpolar i2? Do the mandarins of 3D Systems have concerns over Stratasys’ SAF process?

I think this could be the case.

With HSR, 3D Systems could be positioning for competition against Stratasys in the serial manufacturing market.

But there’s more. If one looks at the HSR technology, it may be possible to dramatically increase the throughput on the device by simply adding more banks of inkjet printheads. The 1m radius of the circular build volume should offer space to accommodate perhaps multiple print heads that would each speed up printing. If one set of printheads can complete a print in time X, then ten sets of print heads can complete a print ten times faster. That would be of great interest to manufacturers.

With 3D Systems’ resources it might be possible to perform experiments that might have been unaffordable by the smaller dp polar operation.

Even if increased speed isn’t their current direction, the acquisition of dp polar is clearly a great strategic move by 3D Systems.

Via 3D Systems, ALTANA and dp polar