Today I’m looking at KINGS 3D, the largest manufacturer of SLA 3D printers in China.

I don’t know much about the company, as they haven’t been one that I’ve seen at any recent major 3D printing events I’ve attended. You may feel the same, but just because they aren’t particularly visible doesn’t mean they are a major provider.

In fact, they claim to be the largest manufacturer of SLA 3D printers for industry in China.

Having launched in 2008, they began using 3D printers internally immediately. However, over time they built their own machines by 2012 and in 2015 launched commercial production of equipment for the public.

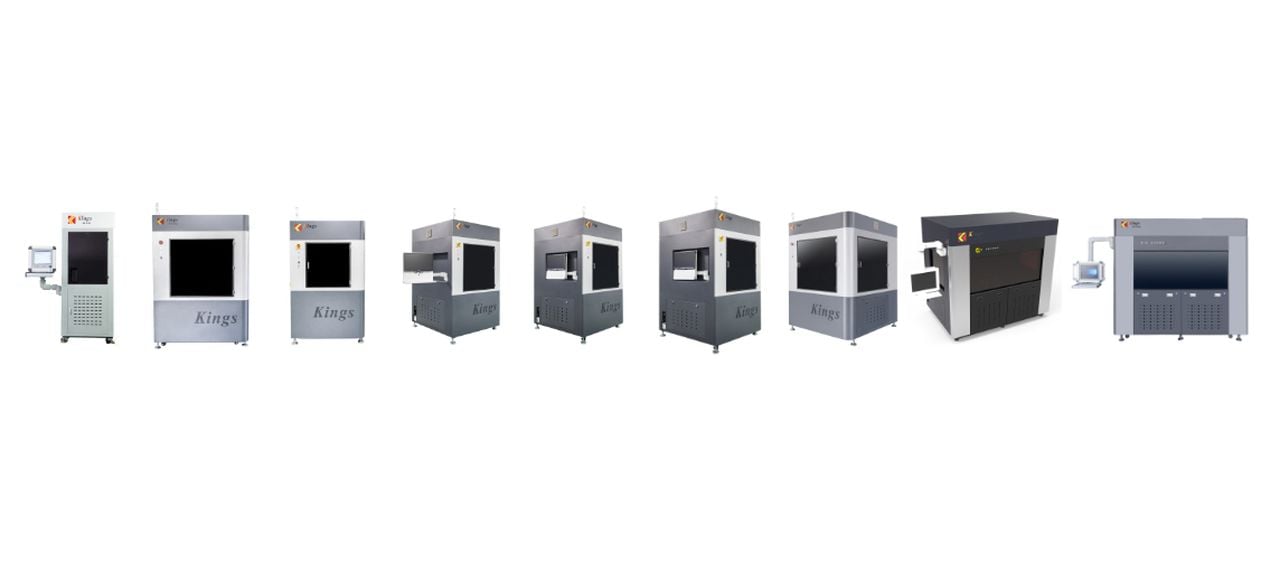

Today the company boasts a rather large lineup of machines, currently thirteen different models by my count. All of them are SLA devices for printing polymer objects, except for one, the KS-350, which is an LPBF device for 3D printing metal.

Their product range includes only machines for industrial use, and the smallest is the “tiny” 3035Pro, which has a build volume of 300 x 350 x 350 mm, and weighs in at 780kg.

At the other end of their range is the massive 1700 system, which boasts an enormous build volume of 1700 x 800 x 600 mm. It’s so large KINGS 3D bills it as a “High-Speed 3D Printer for Automobile Modeling”. Yes, you can build huge auto parts, like entire dashboards, on this device. Note, this machine weighs a massive 3600kg, so you’d better make sure your installation site is ready for such a heavy device.

All of KINGS 3D’s SLA equipment use 355nm lasers, rather than the more commonly seen 405nm lasers. This means that when using these systems you must ensure your photopolymer resin is rated for 355nm wavelengths.

It seems KINGS 3D’s product lineup has a build volume for everyone:

- 3035Pro: 300 x 350 x 350 mm

- 450Pro: 450 x 450 x 350 mm

- 6035Pro: 350 x 600 x 350 mm

- 600Pro: 600 x 600 x 400 mm

- 650Pro: 650 x 650 x 400 mm

- 800Pro: 800 x 800 x 500 mm

- 850Pro: 850 x 850 x 500 mm

- 1000Pro: 1000 x 1000 x 600 mm

- 1200Pro: 1200 x 800 x 600 mm

- 1450Pro: 1450 x 800 x 600 mm

- 1700Pro: 1700 x 800 x 600 mm

- 1700ProHS: 1700 x 800 x 600 mm

- KS-350 (metal): 325 x 325 x 400 mm

You can also clearly understand their machine naming convention, too.

Power consumption ranges from 1.2KVA to 2.2KVA, with the higher consumption for the larger and faster models. The same goes for the laser movement speed, which ranges from 12m/s on the smaller models to 18m/s on the high speed model.

Laser dot size is as small as 0.065mm on the smallest models, while the larger models are a bit larger due to their larger volume at around 0.08mm. The largest machines, the 1700’s, have a laser dot diameter of 0.1mm.

This makes sense, as the more powerful lasers in the larger units are tuned to achieve reasonable print times at the cost of a small bit of additional part resolution.

All machines use KINGS 3D’s proprietary control software, which runs on Windows platforms only.

KINGS 3D clearly has the equipment to meet the needs of many industries, and in fact specifically calls out use cases for automotive, footwear, prototyping, architecture, healthcare, appliances, artwork and more.

As of now it appears they don’t actively market their equipment beyond China, Korea, Thailand and Vietnam. However, if they ever do break out into other areas, they seem to be in a good position to offer products many companies might want for their operations.

Via KINGS 3D