Charles R. Goulding and Warren Buzzell Jr. look at the use of 3D printing at Sweden’s KTH technical university.

The KTH Royal Institute of Technology (KTH) is a public research university in Stockholm, Sweden. KTH is Sweden’s largest technical university, conducting research and education in engineering and technology. The university consists of five campuses combining over 13,000 full-time students and over 1,700 Ph.D. students. In 2022, the university ranked 89th in the QS World University Rankings. KTH has become one of Europe’s leading technical and engineering universities.

KTH has taken considerable strides to stay up to date and remain a pioneer in the advancement of technology. Specifically, KTH has been expanding its use of 3D printing technology for research and educational purposes. Within the last decade, Nano-scale 3D printing research at KTH was added to the Society of Manufacturing Engineers (SME) Innovation Watch List, which was released along with the society’s list of Innovations That Could Change the Way You Manufacture.

The Division of Space and Plasma Physics houses KTH’s student workshop within the Department of Electric Engineering. The workshop contains two Zotrax M200 3D printers and one Zotrax M300 Dual 3D printer. Both printers use ABS filament to fabricate complex structures, but the Zortrax M300 Dual utilizes water-solvable support materials. The workshop also has a Prusa i3 MK3 printer that uses PLA and PETG filaments. The printers are available for recreational and educational use by students and faculty of the university.

3D Printing Research Avenues

KTH has used 3D printing technology as a tool for innovation to identify and experiment with contemporary solutions for modern-day issues. In 2021, a research team at KTH published an article on Multifunctional 3D-Printed Wound Dressings. The team tested and evaluated the efficacy, in vivo, of 3D-printed multicomponent biocomposite hydrogels for enhanced healing with various wound types. The system consisted of hydrogel wound dressings carrying vascular endothelial growth factors and silver nanoparticles with predetermined release profiles.

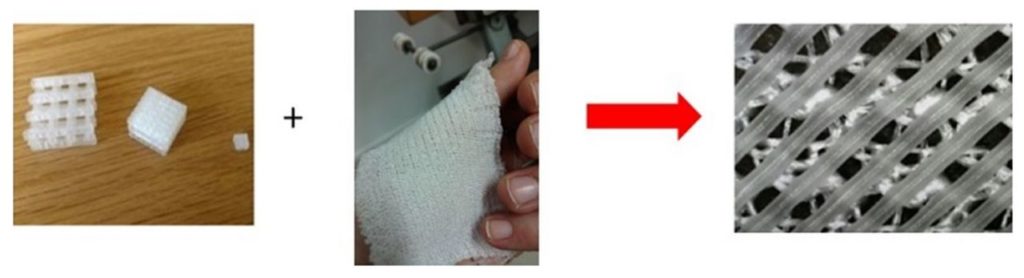

Another research team within the Department of Fibre and Polymer Technology has engaged in innovative research in biomedical sciences by utilizing 3D printing technology to develop knitted degradable scaffolds for soft tissue regeneration. The team designed and developed polymeric biodegradable scaffolds with a micron-configurated interior structure. This venture was an interdisciplinary research project where collaborators from KTH came together to develop 3D scaffolds for biomechanical assessment via simulation software. In vitro cell studies will be carried out after chemical and mechanical characterization is performed on the scaffolds.

In 2021, KTH ordered two Electron Beam Powder Bed Fusion (PBF-EB) 3D printers from Freemelt. PBF-EB is a manufacturing process that uses an electron beam to melt and fuse the material powder to develop products. KTH plans on using a modified version of this system to enhance 3D printing research at the university. The university believes the modified system will enable in-situ synchrotron X-ray studies to provide rudimentary insight into the PBF-EB process.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Applications for 3D printing technology are rapidly growing and the opportunity for more diverse utilization is on the rise. KTH Royal Institute of Technology is a pioneer, continuously finding new avenues to employ 3D printing technology to create novel improvements for products and processes alike. Regardless of the obstacles, KTH Royal Institute of Technology takes pride in its incorporation of this technology for educational and research purposes.