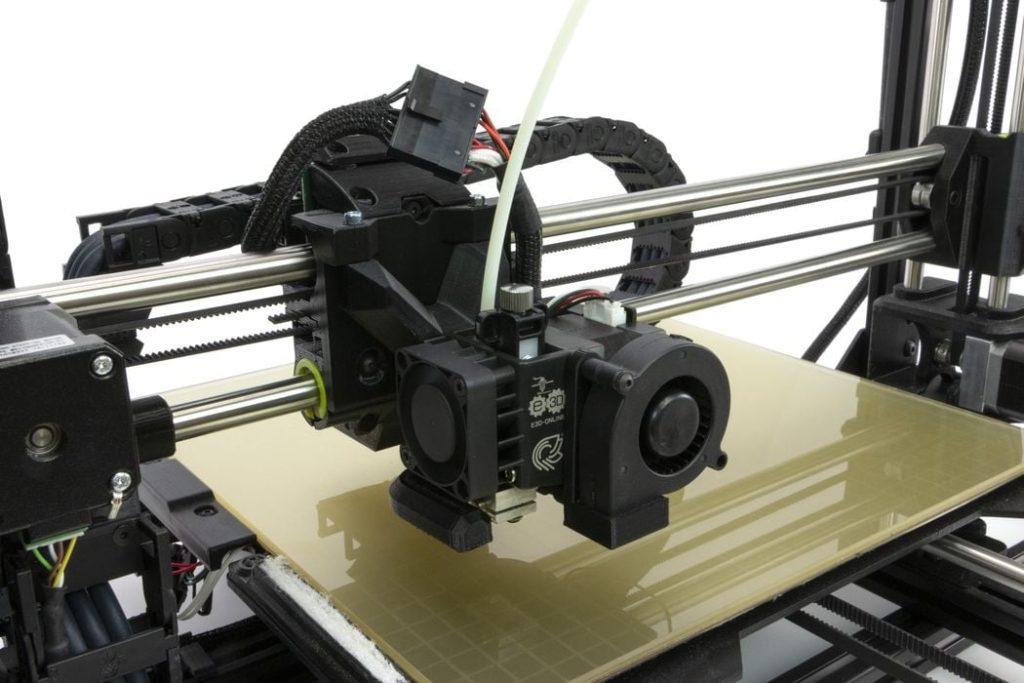

FAME 3D announced yet another toolhead for the LulzBot line of 3D printers: the H175.

The new H175 becomes part of the company’s increasingly broad set of interchangeable toolheads for LulzBot 3D printers. This is a strategy they’ve been using to provide a tremendous amount of functionality with their relatively inexpensive devices.

Currently their slate of swappable toolheads all use the LulzBot Universal Mounting System. This is a design that implements a quick-swap capability and opens up the possibility of using many different specialized toolheads on a single machine.

In their online shop today you can find toolheads offering both their original 2.85mm format and 1.75mm format. The toolheads offer a variety of specialties, including larger or smaller nozzle diameters and hardened steel nozzles for abrasive materials like carbon fiber.

One of the most interesting aspects of the Universal Mounting System is that it provides a route for LulzBot owners to convert their machine from the increasingly rare 2.85mm format to the much more popular 1.75mm format. This is done by installing an adapter on the machine, and then using whichever toolheads are required.

Because the toolhead selection involves both 1.75mm and 2.85mm formats, it’s then possible to operate a 3D printer that can accept both formats — although only one at a time.

Previously the M175 toolhead was announced, the first 1.75mm toolhead carrying the LulzBot logo.

This week FAME 3D announced a new 1.75mm toolhead, the H175.

The H175 uses different components than the M175:

- Hardened stainless steel drive train

- Short filament path

- E3D V6 hot end

- E3D Hemera extruder

FAME 3D explains the advantages of the H175 toolhead:

“The E3D Hemera extruder on the H175 provides unrivalled precision by giving excellent control over stops and starts; considerably reduced stringing and blobbing; and greater filament traction, which means slipping and grinding filament are a thing of the past! Material changes are easy using the quick release lever. A conveniently accessible thumbscrew tensioner allows the you to fine-tune the pressure exerted by the drive gears onto the filament.”

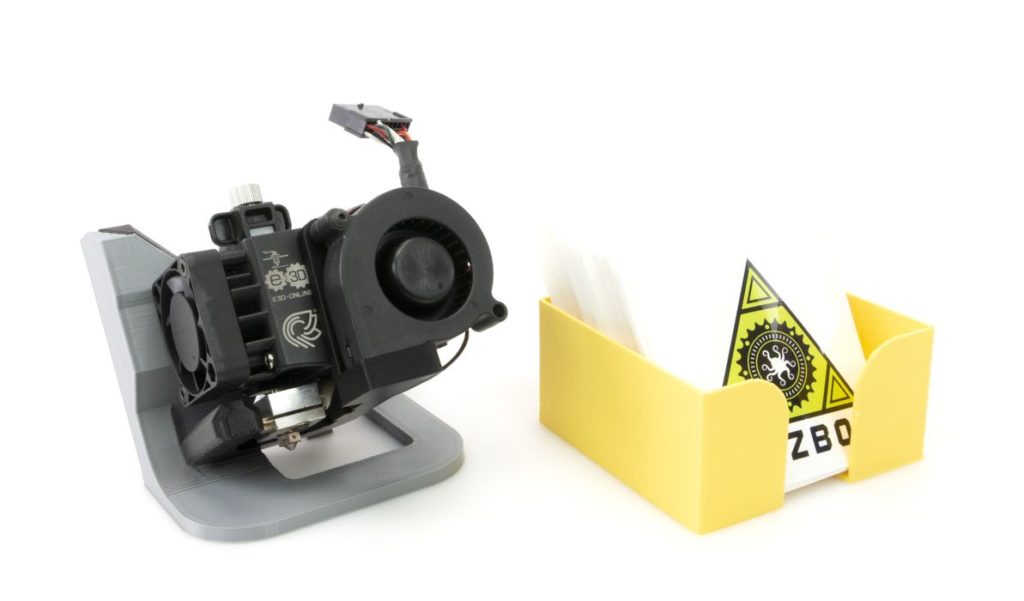

FAME 3D has also designed a sturdy fan duct to direct air 360 degrees around the print, unlike most systems that blow cooling air on only one side of the print. You can see some of the ducting here:

One very good feature of the new ducting system is that they’ve designed it so that you can still see the print in progress. Some ducts, while efficient at cooling, completely obscure the print action, making it difficult to understand whether a print is really working.

FAME 3D said the H175 is compatible with “a broad range of 1.75mm materials from nylon or soft flexible materials to PLA and rigid carbon-filled high-strength materials.”

This suggests that the H175 might be one of the few toolheads you require to get most work done. The H175 also seems to be a toolhead that could be tuned to produce high quality results. Of course, if you require a different nozzle size, for example, it’s easy to swap in a different toolhead.

My suspicion is that we’ll be seeing even more toolheads enter the LulzBot store. The Universal Mounting System is an excellent concept that makes a single 3D printer operate like several different units.

Via LulzBot