Massivit announced a new process called “Cast In Motion” that simplifies composites tooling.

The Israeli company has long lived up to their name by developing huge 3D printers capable of producing enormous objects. They use a process called “GDP”, or “Gel Dispensing Printing”, where a thermoset gel is extruded and instantly cured with UV light. It’s like a weird merger of FFF and SLA technology, but can rapidly produce huge objects.

The problem they’re trying to solve with Cast In Motion (CIM) is the issue of producing composite objects. Normally this is done by CNC milling a shape and then manually layering material on top to form the mold, followed by casting and curing. This process can take up to 19 steps, according to Massivit, and it is also said to be detrimental to the environment.

CIM tackles this problem in an entirely different way, one that I have not previously seen in the 3D print industry.

The process involves using their standard gel extruder, but using a solid but soluble material instead of their normal thermoset materials. Accompanying the extruder is a second toolhead, a dispenser. This second toolhead follows the extruder, but dispenses a “highly durable and robust resin”.

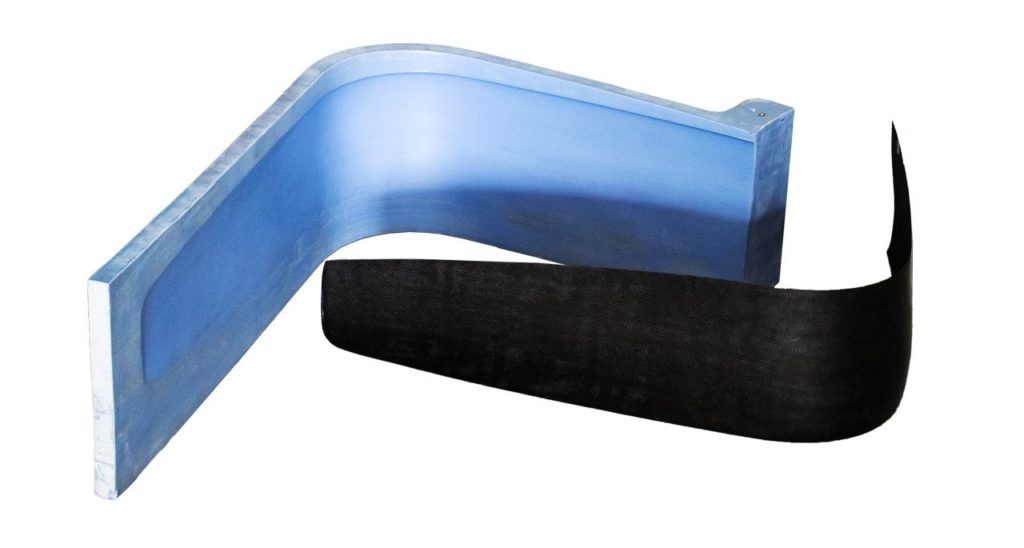

Effectively the solidified gel forms a container to hold the liquid resin while it cures. The resin is deposited gradually, layer-by-layer, up until the final top layer that seals in the resin.

After the resin cure completes, the final step is to immerse the entire 3D print into a water bath. The soluble solidified gel quickly breaks down into very small pieces, finally revealing the completely cured resin part within.

You can see an overview of the process in this short video on their new Massivit 10000 machine:

Massivit said this could reduce the number of steps required to produce the object from 19 to only four. I suspect that in some cases there may be a need to smooth the surface of the object due to the coarse nature of the gel print.

Nevertheless, this seems to be a dramatically simpler and rapid process to produce large resin objects, including molds.

Massivit’s technology is quite different from other 3D printers, and as such has been used in several niche areas, notably to produce large advertising displays. However, it’s very clear that the company has now identified several other ways to apply their unusual 3D printing processes.

The use of CIM could be well-received by manufacturers looking to simplify their workflows. This is an incredibly large market, and it’s possible Massivit may be on the brink of a major revenue breakthrough with this development.

Via Massivit