E3D finally released their high-flow Revo hot end the other week, and it should make life easier for certain types of 3D printers.

The UK company is well-known as the producer of hot ends and extruder components used in many high-end FFF 3D printers. Their most recent hot end product line is the “Revo”. It’s a sophisticated system that allows for quick nozzle swaps, while improving thermal performance and reliability.

High flow nozzles are a new concept in FFF, and they match well with the current trend of high speed 3D printers that are now emerging.

The issue is that these high speed devices are quite thirsty for filament. As the filament flies through the hot end even faster, there is less time for the material to properly soften.

Some high flow systems simply stretch the length of the hot end to enable a longer contact duration. However, those systems tend to be quite tall and are often awkward to install on desktop systems, to say nothing of their price.

Some time ago Bondtech came up with a unique idea: instead of lengthening the filament path through the hot end, why not simply increase the metal surface area to more efficiently heat the material? They devised the CHT hot end, which internally splits the filament to do just that. From the outside, the nozzle looks the same as any other nozzle, however.

It turns out that E3D teamed up with Bondtech to help develop the new high flow Revo hot end. It has a similar, but somewhat different design than Bondtech’s.

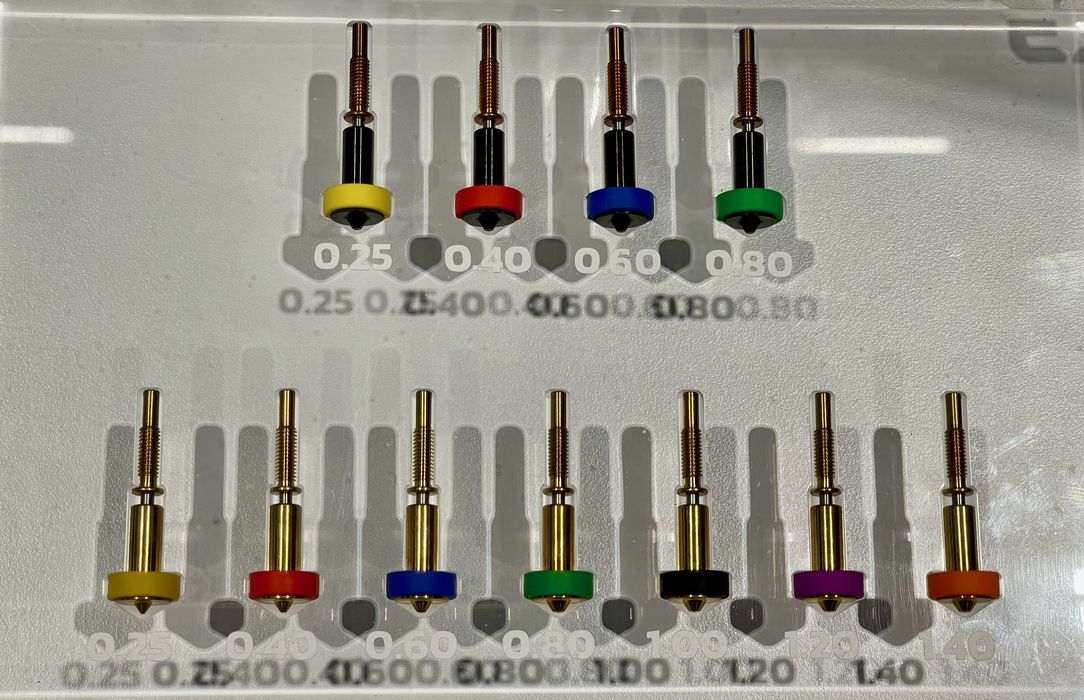

As you can see in the image at top, the Revo High Flow hot end splits the material and provides an ability to heat it far more rapidly.

The High Flow includes a whopping 60W heater core that should easily be able to handle many different materials at high speeds, even unusual engineering materials.

E3D has produced the High Flow Revo system with a number of different nozzles, including 0.4mm, 0.6mm, and 0.8mm. All Revo nozzles are color coded for easy identification. Interestingly, they’ve added 1.0mm, 1.2mm and 1.4mm options that would be quite welcome on large format systems printing huge objects: massive extrusions at high speed is a good combination.

As for the Revo line in general, E3D told us they are selling very well, and they are now releasing the remaining variants to round out their capability.

One tidbit we learned is that Prusa’s new MK4 and XL machines apparently each use E3D components, although this might not be immediately seen.

One wonders if Prusa Research is considering using the new Revo High Flow system, but you never know what might come up in discussions between the two companies.

Via E3D