Charles R. Goulding and Matthew Selman examine the growing use of 3D print tech in Blackstone’s new acquisition.

In a deal that values the business at US$14B, Emerson Electric Co. will sell the majority stake in its Climate Technologies unit to Blackstone Inc. The Climate Technologies business segment includes all of the products and services from the HVAC and refrigeration markets, as well as the Copeland compressor business. This business represents about US$5B of fiscal 2022 sales. Emerson will receive about US$9.5B cash upfront, with an additional US$2.25B when the deal is closed some time in early 2023. Emerson will use the cash to acquire more businesses within the automation industry to continue to invest in their future operations that also have an increased focus on 3D printing.

Emerson & 3D Printing

Stemming from the COVID-19 pandemic, Emerson, a large manufacturing business segment, has had an increased emphasis on the importance of automation within its manufacturing plants. Social distancing and a more limited amount of available workers led to required changes to working operations within the manufacturing plants.

While they made some responsive changes to directly combat the pandemic, such as expanding their plants in size, Emerson has learned that automation is the long-term solution to solidify and improve manufacturing operations. They are committed to and are in the process of, automating all of their over 200 manufacturing plants located throughout the globe. Automation technology helps improve the efficiency of operations and fills in the gaps created by the frequent labor shortages present in manufacturing.

Emerson has also been exploring the many benefits of implementing 3D printing throughout its supply chain. Similar to automation, 3D printing also improves manufacturing capabilities by having the ability to build specific products on demand and by finding the best product design more easily. The best product design is found easier because 3D printing allows for iterative prototyped designs to be made at once so that real-world testing can be used for evaluation and comparisons.

Emerson 3D prints control valves that are used for power generation, refining, oil and gas, and chemical industries. All of the manufacturing plants for these industries can be improved upon with automation, and therefore with 3D printing too. Automation equipment is often specific to different products, so 3D printing can be used to create alternative designs of these parts on demand.

Instead of relying on simulations, they can physically test the designs for a quicker and more “real” design process. As Emerson continues to increase automation within its factories, their use of 3D printing will also increase. Emerson believes there are “endless possibilities for this technology, and [they] are excited to dig in and uncover the next great application.”

Blackstone & 3D Printing

Blackstone is one of the largest asset management companies in the world, as it oversees about US$951B in assets. Much of the capital, about US$577B, is invested in global real estate. The purchase of Climate Technologies adds a significant HVAC resource to Blackstone’s portfolio.

3D printing has been growing within the HVAC industry. If a specialized design is required, one can be more easily with the use of 3D printing. Additionally, the useful life of HVAC products, such as heat exchangers or other air conditioning parts, can be extended with the use of 3D printing.

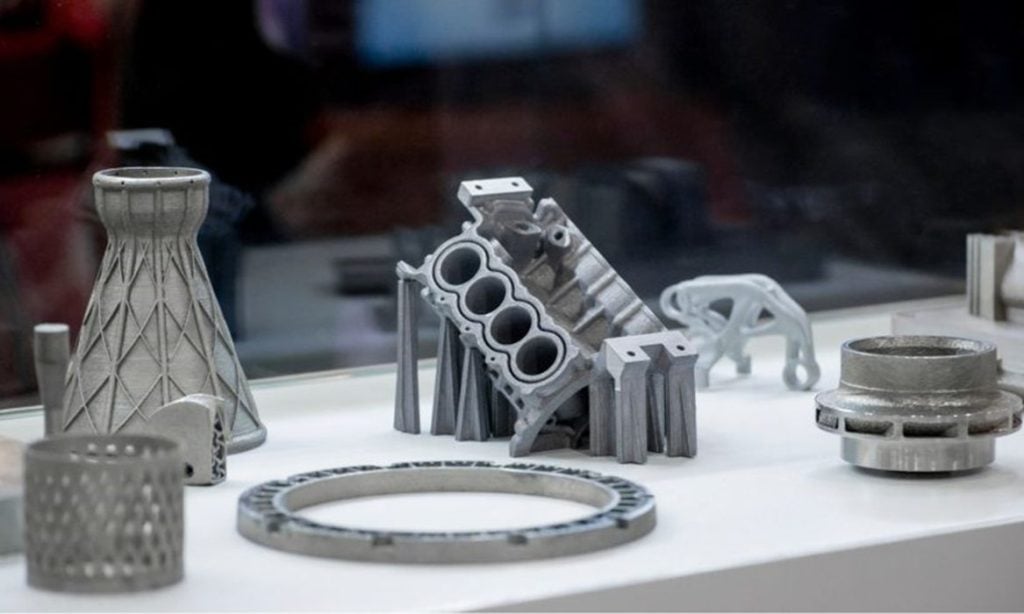

The process of 3D printing results in one solid object with no seams due to the continuous printing process. The absence of seams means that the product will not leak as frequently as its non-3D printed counterpart. 3D printing can also be used for specific repairs, as depicted in the above image.

3D printing has a lot of beneficial applications within the HVAC industry. Blackstone’s purchase of Climate Technologies appears to be a strategic investment from one of the world’s best. They will surely utilize the advancements in the 3D printing industry to their advantage, specifically for their new HVAC investments.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Emerson and Blackstone have recently agreed on a deal that will leave Emerson with a significant amount of cash. They plan on using the money to invest further in the automation of all of their manufacturing plants located throughout the world. Automation and 3D printing go together, as both advancements look to improve manufacturing capabilities and efficiency.

The full potential and usefulness of 3D printing are yet to be seen on a grand scale, however, Emerson now has the potential to do so. Blackstone, on the other hand, is looking to expand their investments in the HVAC industry. 3D printing is playing an increasingly important role in the industry, and Blackstone can unlock its full potential with its purchase of Climate Technologies. Blackstone and Emerson are looking to set themselves up best for the future. A future that will be led by the advancements in 3D printing.