Researchers have used a unique process to develop an enzyme that dissolves thermoplastic.

3D print waste is a problem, and one well known by any 3D printer operator. Stray filament, support structures, failed prints and unused iterations all contribute to the pile of junk plastic that sits near every 3D printer.

Getting rid of that waste is becoming an issue. It could be simply sent to the landfill, but that’s not a good idea because landfills are generally limited in capacity, and more importantly you really don’t want to introduce even more sources of micro plastics into the environment.

But what can you do?

One option is recycling, where the thermoplastic is remade into filament or other products and re-used. However, while it seems like the obvious solution, it in practical terms most often doesn’t work. This is because the world is covered in countless different variations of thermoplastics and it’s impossible to sort them into categories suitable for recycling. The only practical approach I’ve seen is to collect empty bottles from a specific drink company. That ensures the thermoplastic chemistry is the same, but it leaves the other 99% of plastic waste for the landfill.

Another option is to burn the waste plastic. This gets rid of it, but produces noxious fumes that are probably not good for the environment. I’ve also seen piles of thermoplastic melted down into bricks or artwork, but that isn’t really disposing of it.

So most of us just keep our piles of plastic scraps until you have to eventually deal with it.

Now there may be another solution on the horizon: enzymes.

These are peculiar molecules that can chemically break down a material upon exposure.

The idea here is to collect thermoplastic scraps and mix them with enzymes to rapidly break down the polymer chains.

This has been done in the past, but there are significant constraints on the temperatures and acidity of conditions for success. It’s also been a very slow process.

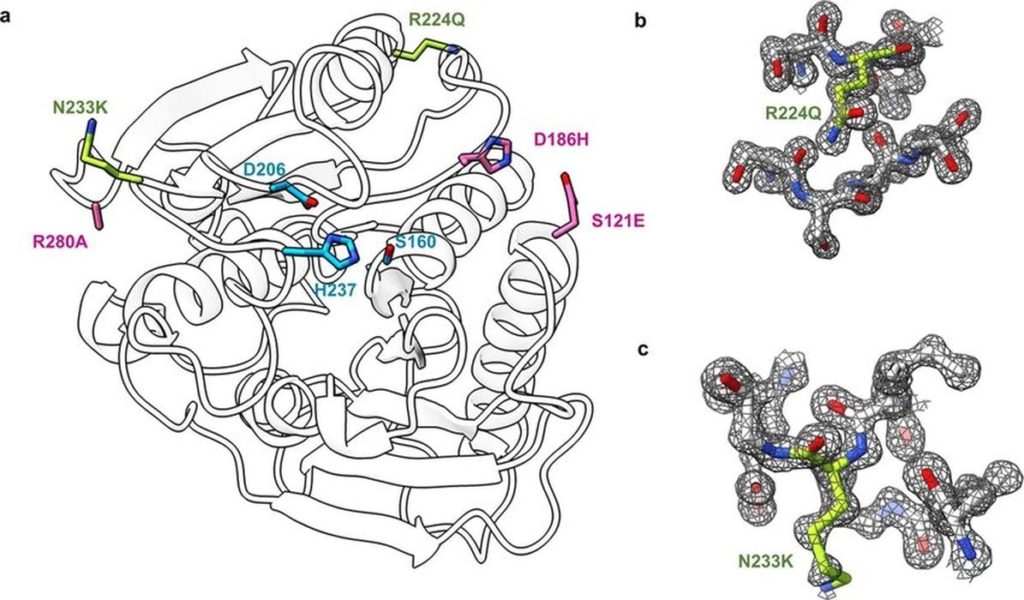

The new research has developed a far more effective enzyme that is able to attack PET material.

The researchers say that the enzyme, FAST-PETase, is able to almost completely break down an amount of PET within a single week in an environment between 30-50C at various Ph levels. They explain:

“We demonstrate that untreated, postconsumer-PET from 51 different thermoformed products can all be almost completely degraded by FAST-PETase in 1 week. FAST-PETase can also depolymerize untreated, amorphous portions of a commercial water bottle and an entire thermally pretreated water bottle at 50C.”

The most interesting part of this project was how they developed the enzyme. They used machine learning approach to engineer the new enzyme for robust use and fast action.

One could imagine a relatively small device that has a warm chamber where the enzymatic reactions could occur. If such a device existed, it could be a standard accessory for 3D printers: just toss in your PET scraps and they dissolve away.

But what about other 3D print materials? This is where it gets really interesting.

If the researchers successfully used the machine learning algorithm to engineer a PET-compatible enzyme, they might also be able to engineer a different enzyme for other thermoplastic polymers, such as PLA, ABS or others.

If that was the case, then that 3D print accessory device might be infused with several different enzymes that can attack all common 3D print materials. Then you’d have a single “chemical wastebasket” to throw all your scraps in as they are produced.

That’s a product I would definitely want. Would you?

Via Nature