Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

Massivit

Massivit announced two new gel materials for their massive 3D printers: DIMENGEL 20-FR and DIMENGEL 300. DIMENGEL 20-FR is a flame-retardant material, that should open up some new applications for the large-format 3D printer manufacturer. DIMENGEL 300 is a rigid, translucent material that can be used for applications requiring back-lighting or illumination.

Farsoon and Covestro

Farsoon announced a collaboration with Covestro to for AM polymer materials. Covestro is now testing a variety of new materials, including TPU, PP and PBT on Farsoon equipment. This will lead to certification of these materials for Farsoon devices.

Kimya Recycled PETG

Kimya announced a new filament made from recycled materials. Their new PETG-R product is 100% recycled if purchased in the natural color, and 97% recycled material for the black and white version. Kimya explained the properties of the new PETG-R material was very similar to their non-recycled PETG-S material.

Raise3D MetalFuse

Raise3D announced the availability of BASF’s MetalFuse, a polymer/metal powder combination. The material can be used to 3D print “green” parts that can then be sintered to form complete metal objects. Raise3D said:

“Raise3D MetalFuse system has been developed in close collaboration with BASF Forward AM

as material partner, and it’s the first end-to-end fully integrated in-house printing ecosystem

using Ultrafuse Metal Filaments from BASF Forward AM.”

This is not just a material, but an entire process, as Raise3D also announced Forge1, a catalytic debinding furnace and a sintering furnace to be used in the metal production lifecycle.

This announcement effectively makes the Raise3D equipment able to produce metal objects!

Desktop Metal 420 Stainless

Desktop Metal announced the certification of Grade 420 stainless steel (420 SS) for their production system. They explain:

“A martensitic heat-treatable stainless steel, 420 SS is characterized by its high strength and hardness as well as its corrosion resistance to the atmosphere, foods, fresh water, and mild acids when in a fully hardened condition. 420 SS is a common material used extensively across a variety of applications such as surgical and dental instruments, ball bearings, gear shafts, pump and valve components, fasteners, gauges, hand tools, and high-end cutlery.”

This new material is usable in the company’s single pass jetting Production system to produce end-use metal parts.

Sinterit Carbon Fiber

Sinterit announced a new PA11 material: PA11 CF, or carbon fiber. This is a nylon powder reinforced with tiny segments of chopped carbon fiber that will add significant strength to any parts produced on their SLS systems. It’s also a “bio-derived” material.

Sinterit explains:

“PA11 CF is one of the strongest and most versatile materials available on the powder market dedicated to SLS printing technology.

It has great mechanical performance with tensile and flexural strength (81 MPa and 100 MPa) together with a great thermal resistance (HDT up to 191°C).”

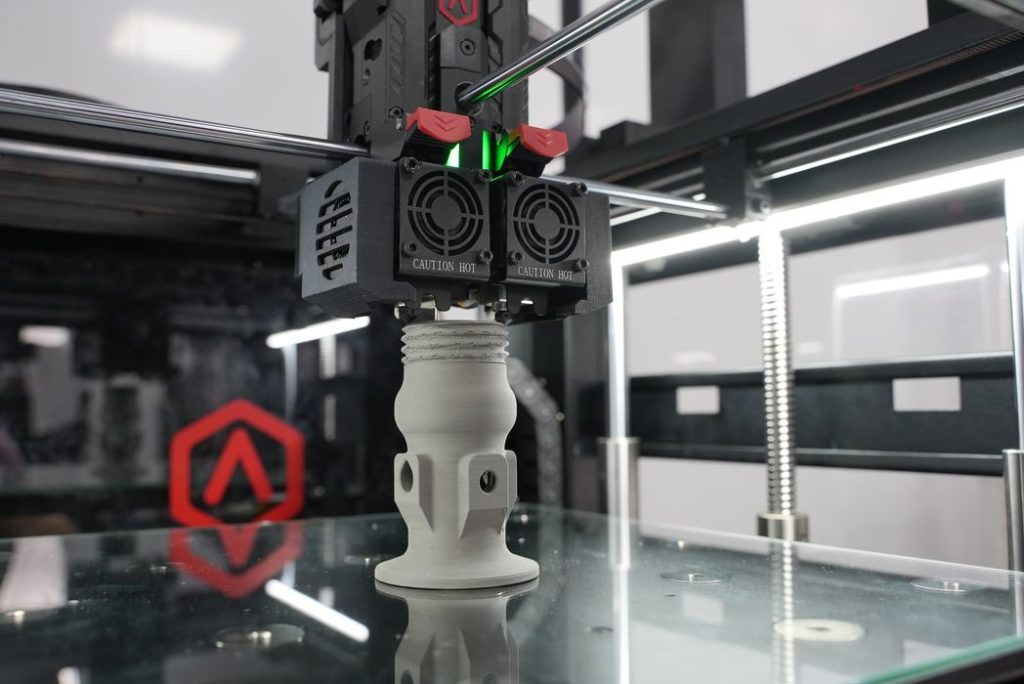

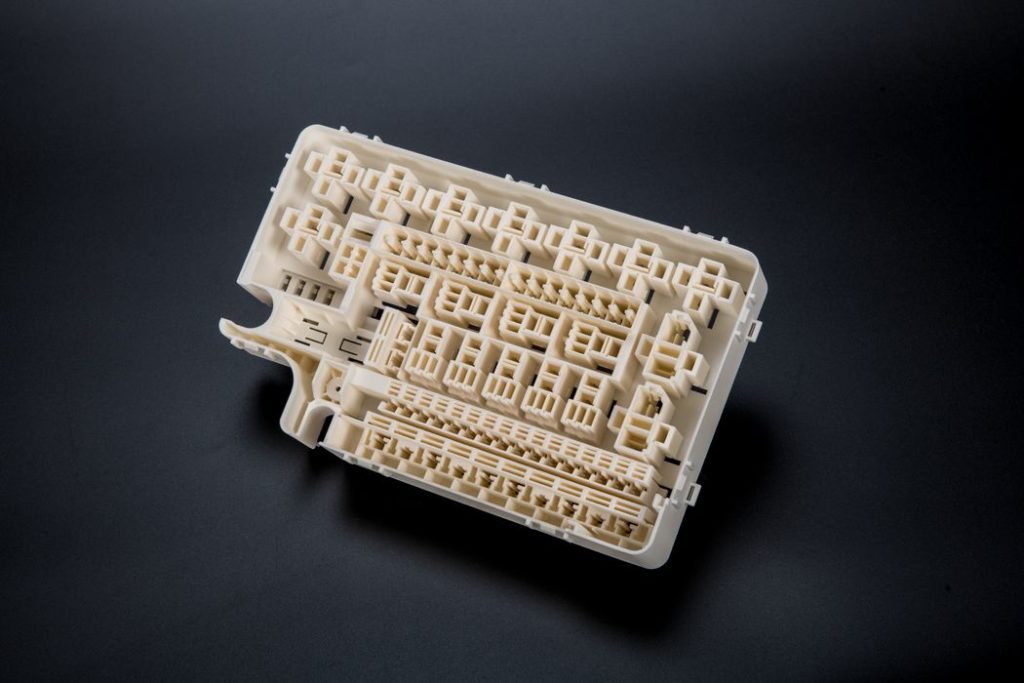

INTAMSYS Breakaway Support

INTAMSYS introduced two new breakaway support materials, SP5040 and SP5080. These are specifically designed to work with high temperature materials ULTEM 9085 and ULTEM 1010, respectively. They are engineered to have very high heat resistance, making it possible to use them in the sizzling build chambers printing those materials. As “breakaway” materials, they don’t adhere to ULTEM, and can thus be pulled off easily by hand after printing completes.