A new research paper explores the concept of 3D printing using UAVs.

UAVs, “unmanned aerial vehicles”, or drones, are now a popular tool, and are even used by consumers. But what would they have to do with 3D printing?

3D printing is the act of intelligently depositing or solidifying material in an additive sequence to gradually build up an object. This is done using a variety of processes, including dropping liquids, exposure to UV light, extrusion, etc. But in the end they are all doing the same thing: building up an object.

That can be quite slow, and there are techniques to make printing occur faster. A common approach is to add more toolheads that can operate in parallel. Some dual-extrusion machines can print almost twice as fast, for example.

My fantasy is an unlimited amount of toolheads, all working at the same time to build up an object very quickly. I can imagine the toolheads swarming over the build surface, each doing a small amount of work that adds up among all others.

That’s fantasy, of course, as it would have to be done with some form of drone because conventional toolheads would certainly crash into each other.

Very limited research has been done using drones to 3D print, but a new paper entitled, “On Experimental Emulation of Printability and Fleet Aware Generic Mesh Decomposition for Enabling Aerial 3D Printing” takes a deep look at how this might actually be done.

They explain:

“The experimental demonstration of the overall autonomy focuses on precise motion planning and task allocation for a UAV, traversing through a series of planned space- filling paths involved in the aerial 3D printing process without physically depositing the overlaying material. The flexible multi-DoF (degrees of freedom) aerial 3D printing is a newly developed framework and has the potential to strategically distribute the envisioned 3D model to be printed into small, manageable chunks suitable for distributed 3D printing.”

Drones offer six degrees of freedom, so that does indeed open up many possibilities.

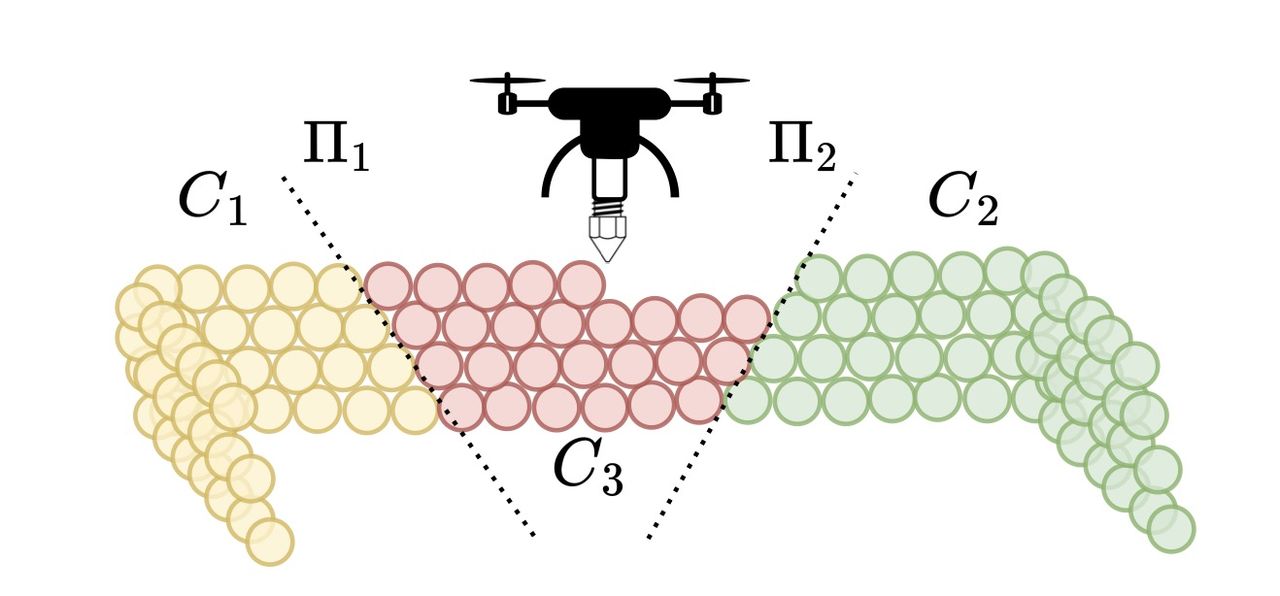

Development of a toolpath for a drone is not straightforward. The drone has a boundary box for its own operation in order to maintain stable flight and not collide with a partially built structure. Complicating the path is that there should be multiple drones in operation, each assigned to specific zones within the print.

The researchers decided to decompose the object into “chunks” that have “minimal manufacturing interdependencies”, which would permit parallel operations. In other words, many drones. They explain:

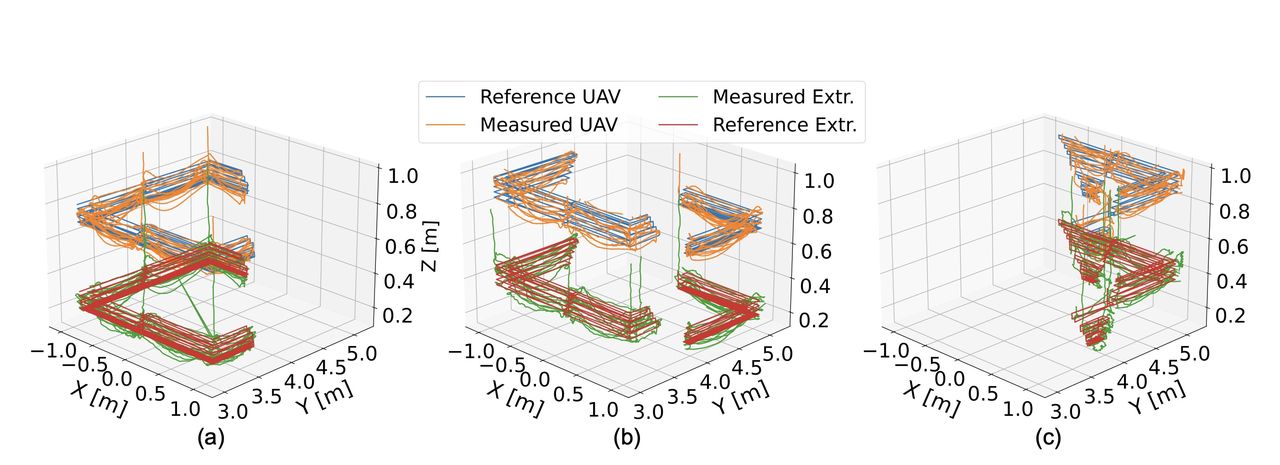

“The experimental emulation essentially considers the overall autonomy, incorporating precise coordinated motion planning of a UAV, while traversing a series of planned space-filling paths. It effectively utilizes a Model Predictive Control (MPC) strategy, with careful consideration of the unique attributes of the UAV model, ensuring necessary movements for successful execution.”

The architecture of their process involves four steps before the drone takes flight:

- Chunking algorithm

- Slicer path generation

- Task allocator

- Nonlinear Model Predictive Control

Then the drone takes over:

“Once a chunk is designated for printing, a prescribed sequence of actions must be executed to initiate the printing process. Each chunk mesh is given to the slicer that is con- figured with precise parameters including UAV and extruder dimensions and material deposition variables, adjusted to suit the project’s specific requirements. It is transformed into the adequate G-code commands for effectively manufacturing the chunk.”

The researchers did not physically implement this concept and power a set of drones to build an object. Instead they used a simulator to test the concept’s quite complex algorithms to see if they worked.

It seems that they were successful in the simulation, and that can mean only one thing: let’s try this for real.

Via ArXiv (PDF)