SPONSORED CONTENT

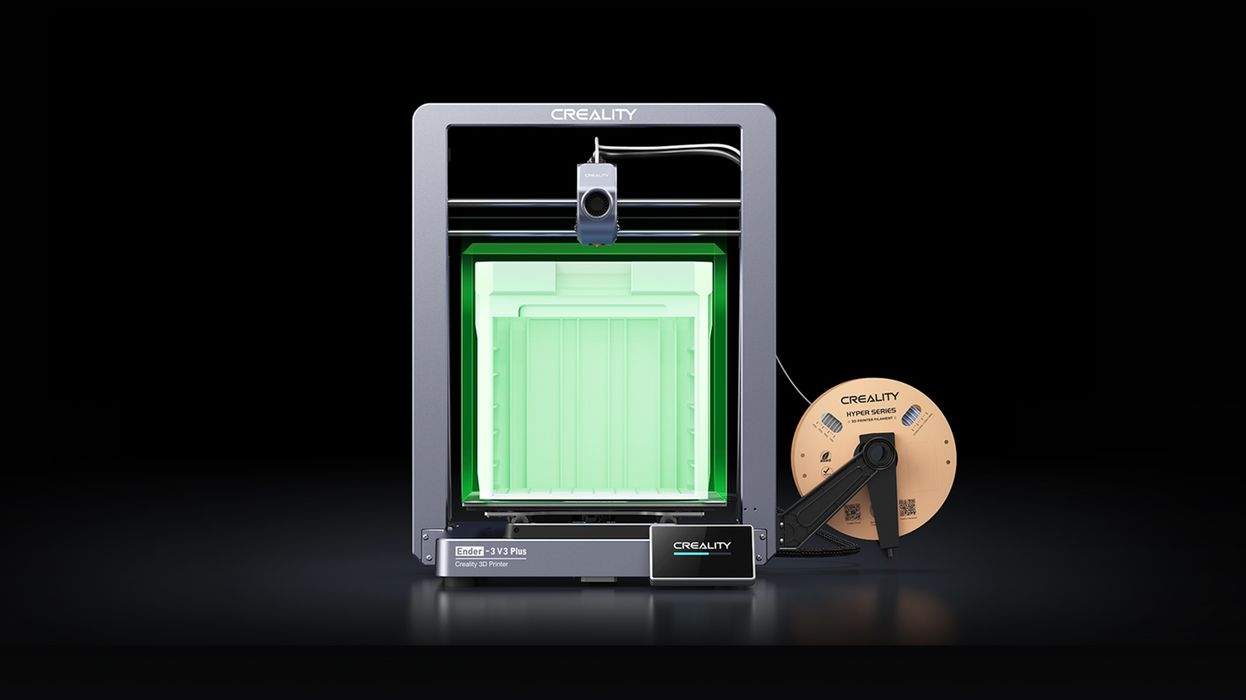

Creality announced another new 3D printer today: the Ender-3 V3 Plus.

This follows their previous announcement of the Ender-3 V3 only nine weeks ago. That machine introduced the revolutionary concept of a “CoreXZ” motion system, something never seen previously on desktop 3D printers.

CoreXZ is an ingenious solution to the need for rapid 3D printing. Previous Ender-3 models used the i3 motion system concept, in which the build plate moves forwards and backwards on the Y-axis, with lead screws raising and lowering the Z-axis. While this enabled lower cost equipment, it isn’t great at high speeds.

CoreXY was introduced by other companies to solve this problem, which kept the build plate from moving. However, it requires quite a bit more hardware and therefore prices are a bit higher for such systems.

Creality’s CoreXZ concept is a brilliant compromise: it tilts the “Core” axes to allow for low cost construction, yet retains the high speed capabilities. While the Y-axis build plate still moves, the Z-axis moves far faster and with much greater accuracy. The Y-axis has not one, but two powerful motors to ensure the Y-axis movements can keep up with the X and Z axes.

The result is much improved surface quality on prints using the CoreXZ approach, and that’s what you get with the Ender-3 V3. It’s also quite fast, able to 3D print a #3DBenchy in only 13 minutes.

Now there’s the Ender-3 V3 Plus. What’s different?

The Plus retains many of the features of the V3, including print speeds up to 600mm/s, accelerations of up to 20,000 mm/s/s, quick swap nozzles, beefed up hot end, die-cast metal frame, advanced cooling system and high torque extruder. The V3 includes a fully automated calibration sequence that requires nothing beyond pressing a button. The V3’s design is intended to simplify maintenance, which we expect to see on the Plus as well.

But the big difference is, well, “big”: the Ender-3 V3 Plus’ build volume is now 300 x 300 x 330 mm. That’s a 58% larger volume than the Ender-3 V3’s 220 x 220 x 250 mm.

That should enable printing of larger parts, something that’s easily possible with the tremendous print speeds of this device. In addition, it would be possible to swap nozzles for higher diameters to increase print speeds even more.

The larger build volume also permits printing of more smaller parts within a single job. That might be quite useful in large print farms, where throughput is king. Creality believes the Ender-3 V3 Plus would be ideal for print farms due to its connectivity and remote control capabilities.

Creality said the Ender-3 V3 Plus is able to print in a wide variety of materials, including PLA, TPU, ABS, PETG and even PLA-CF. This should make the device quite suitable for developing prototypes using many engineering materials.

Both the V3 and V3 Plus directly connect with Creality Cloud to allow for remote 3D printer operations and monitoring. The cloud system also includes access to a wide range of pre-made 3D models that can be easily 3D printed, right from the app.

Creality is making the Ender-3 V3 Plus available for pre-order starting today, and you can do so on their official website.

Via Creality