PrusaSlicer 2.6 has been released, and it includes quite a number of very useful new features.

Prusa Research has aggressively developed the popular slicing tool, as its power directly enhances the capabilities of their customer who have purchased 3D printers. But because the software is open source, it’s also used by many others in the industry as the default slicing tool. Ultimaker Cura and PrusaSlicer are the two most popular slicing tools for desktop FFF job preparation.

What’s new in version 2.6? It’s not a surprise, as the features have been available for several weeks under the company’s beta testing program. Interested parties could have downloaded a beta version and performed their own testing ahead of this week’s official release.

Nevertheless, the features in version 2.6 are perhaps one of the biggest upgrades to PrusaSlicer in some time.

Organic Supports

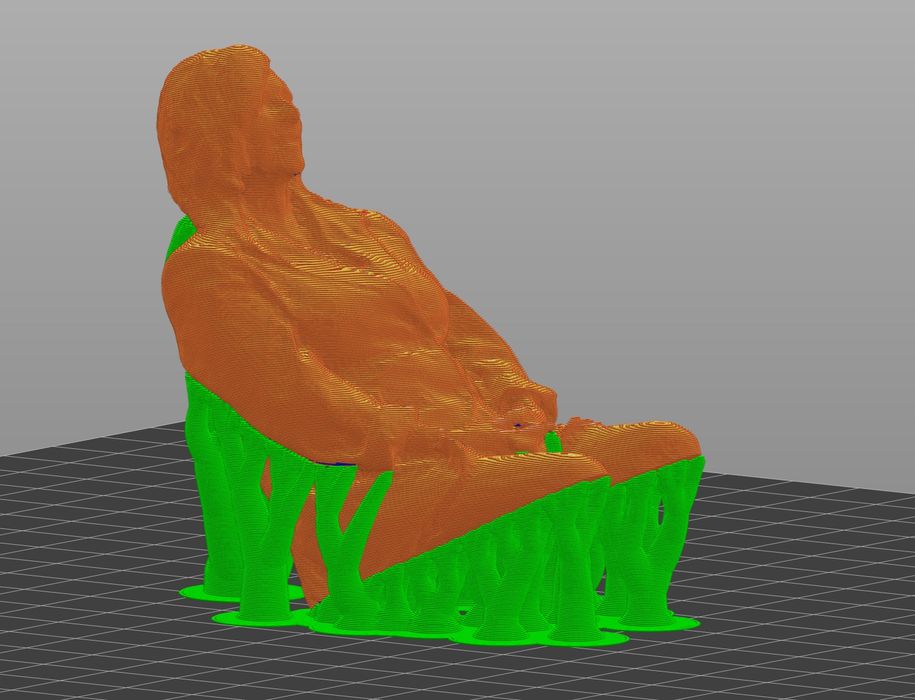

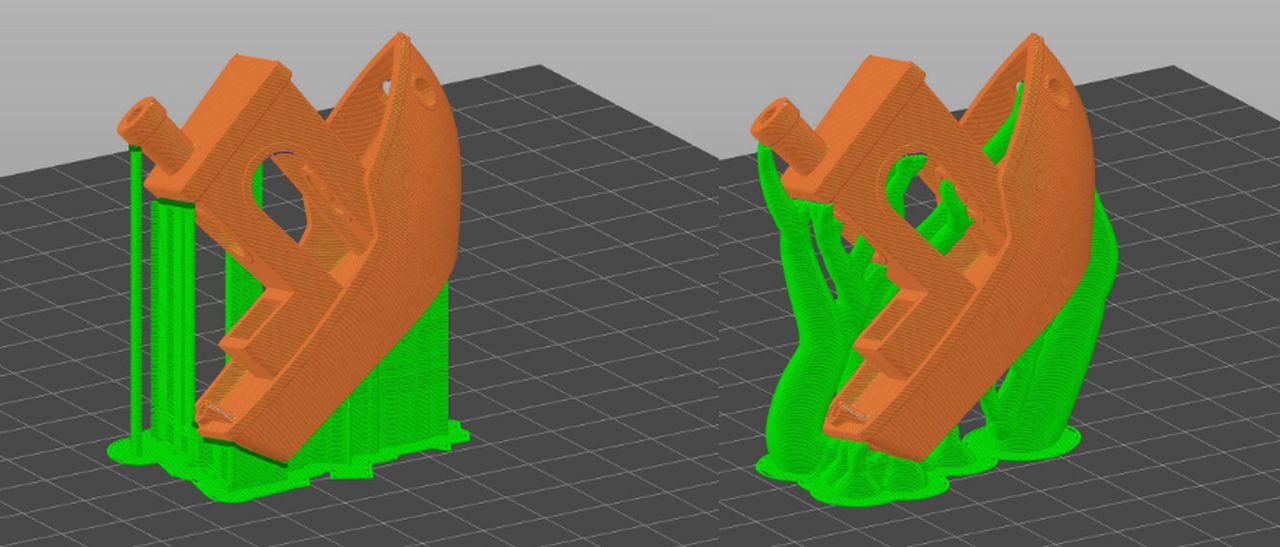

The flagship new feature is Organic Supports. These are a new variation of the earlier Tree Supports, but with far more intelligence and sophistication, leading to the change in name.

Normal supports follow a grid approach, where a grid structure is built under any relevant overhang. This works, but wastes considerable material and almost always is difficult to remove. Those difficulties inevitably result in scarred surfaces that degrade quality.

The new Organic Supports are much like a tree the “grows” up the sides of the print to reach only the points that actually require support. This decreases not only the amount of support material used, but also the amount of unnecessary surface contact that spoils print quality. The organic supports are also less spindly than grid-style supports, particularly for taller support scenarios.

A complementary feature is the automatic support painter. Here the software analyzes each segment of extrusion to determine, based on angle, orientation, nearby extrusions, weight and other factors to determine if support is actually required.

It’s as if an expert 3D printer operator grabbed your keyboard and swiftly painted all the spots requiring support.

Once this is done, the organic supports can then support these regions to result in an optimal support configuration.

Does it work? Well, my testing showed that organic supports are well designed, but in at least a couple of tests I found that organic supports actually used MORE material than standard supports — but the contact points were more optimized. In other words, it’s probably best to test both approaches to determine what works best for your particular model.

There’s a very interesting side effect that emerges from this capability. Prusa Research explains:

“From our internal and external alpha/beta tests, we’ve seen that the addition of Organic supports changes how we think about FDM 3D printing and even 3D modeling. Models can now be printed in orientations that were previously unthinkable (mirroring SLA printing capabilities) and supports for even the most complex shapes are typically easy to remove.”

That alone is reason enough to upgrade to version 2.6.

More Features in PrusaSlicer 2.6

But there’s more!

A new “text embossing” feature allows the operator to plant raised text using a font of choice anywhere on the model. Normally this is done using external CAD tools, often using awkward methods that are challenging to learn. However, now it can be done directly in PrusaSlicer — and it even works on curved surfaces.

The planar cut tool has been enhanced to allow cuts at any angle. But more interesting is that there is now an associated capability to define connectors between the parts. This means that a large print that won’t fit into the build volume can be quickly chopped up and printed in sections. Those sections are now guaranteed to fit together properly because of the addition of the connectors. This is a feature that I’ve been seeking for many years.

A measurement function is added to calculate distances between points on the models, and there’s now a way to slow down the extrusion when printing overhangs to enable better cooling and solidification. This should increase print quality notably.

There are still more features, and I encourage you to read Prusa Research’s lengthy post on the upgrade, and also I recommend upgrading as soon as you can.

Via Prusa Research and PrusaSlicer (download)

Kerry,

I only wish that adaptive layer heights worked with organic supports. New feature suggestion?

RAH