Charles R. Goulding and Preeti Sulibhavi look at the challenge and opportunities facing bicycle manufacturers.

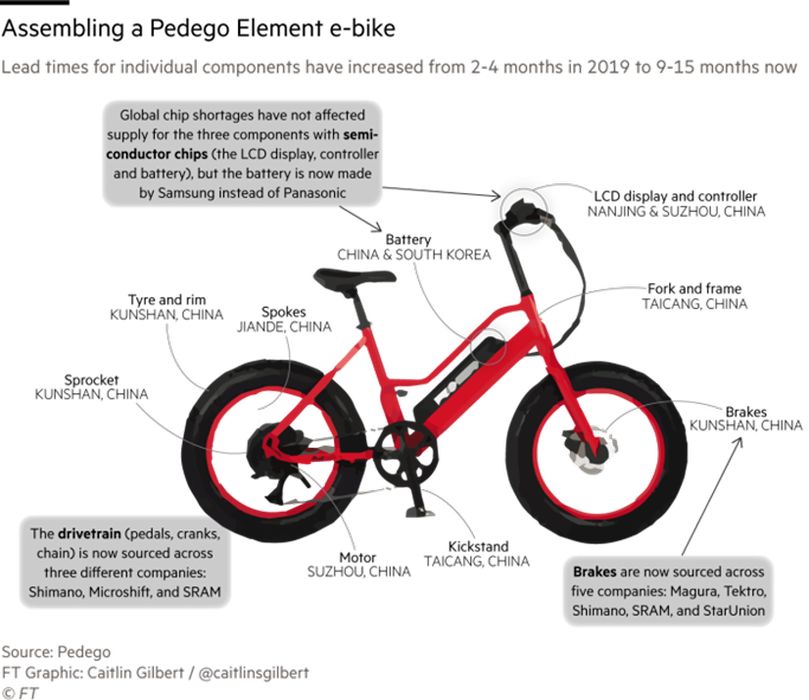

On December 23, 2021, the Financial Times had an extensive article describing the vicious cycle for Pedego as supply chain woes take their toll. The article provided the details on Pedego’s specific supply chain components and the company names of the active suppliers.

Pedego and 3D Printing

Pedego is a California-based world-class manufacturer of quality electric bicycles and accessories. The image at top demonstrates the current supply chain situation challenging them and the industry as a whole. With many companies sourcing various parts and components from a myriad of places, producing a bicycle is not as simple as it once used to be. That is especially true when considering specialty products such as e-bikes.

The US bike industry imports almost 100 percent of its inventory (according to Human Powered Solutions, a consultancy firm). Pedego, uses eight factories spread across Asia (five in China, two in Taiwan and one in Vietnam). It is not difficult to see how challenging it has been for the company to meet surging demand with each component allocated to a different country in Asia.

We have previously covered, on Fabbaloo, 3D printing can help resolve product parts and components issues brought on by supply chain constraints. There are several bicycle components that can be locally 3D printed (as opposed to outsourcing to foreign factories). This includes cycling accessories as well.

Interestingly, many of Pedego’s suppliers are well-known users of 3D printing.

Magura and SRAM Bikes

Not only are bikes from Magura and SRAM high quality, but these two companies are doing some interesting work with 3D printing.

Magura has utilized metal 3D printing to fabricate their new Magura HC Loic Bruni brake lever. The process of 3D printing the brake lever helped to optimize the product for a wider lever reach and a hard brake feeling. With a short 1-finger lever blade creating an aggressive braking feel, the lever also offers comfortable ergonomics.

SRAM has used Autodesk generative design to create a crank prototype that is AI-optimized and 3D printed. SRAM has put a lot of effort into the 3D printed design approach and they were able to let AI dictate the optimal form for the prototype crankset based on active forces and various automated manufacturing processes, including 3D printed sintered titanium crankset prototypes.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

For anyone who has tried to purchase a quality bicycle since the Pandemic began, it is obvious that waiting is part of the game here. Companies in the industry, such as Pedego, may be able to overcome supply chain hurdles and restock their inventories by integrating 3D printing into their manufacturing practices.