Photocentric has teamed up with CoreTechnologie to supercharge creation of 3D models for their printers.

UK-based Photocentric has come a long way from their beginnings as a chemical provider of photopolymer resin. Today they boast a varied lineup of 3D printers themselves, including several large and productive industrial models.

The innovative company has taken several fascinating steps and now they’ve done another. A new partnership with CoreTechnologie.

CoreTechnologie’s 4D_Additive

CoreTechnologie is the producer of “interoperability solutions for the future”, with a series of 3D software tools. The arrangement with Photocentric focuses on CoreTechnologie’s 4D_Additive, a 3D print job preparation system.

When I say “job preparation”, I suspect most Fabbaloo readers have thoughts such as “part orientation”, “slicing” and other basic job preparation functions. These are indeed included with 4D_Additive, but the tool includes much more functionality that is quite advanced.

4D_Additive is capable of:

- Analyzing 3D model geometries to ensure they comply with wall thickness tolerances

- Detecting thick areas that might develop thermal issues during printing

- Sophisticated nesting algorithm to pack models into a build volume

- Automatic optimal part orientation

- Automatic support structure generation according to process and material

- Automatic 3D model repairs

- Hollowing solid parts

- Generating lattice structures (16 styles)

- Splitting large parts into sections with various joint designs

- Reading 24 different CAD input formats

- And much more

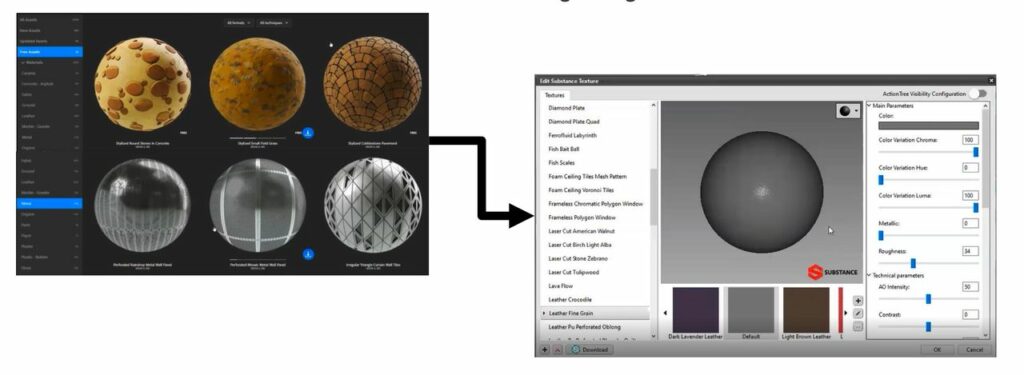

If that wasn’t enough, 4D_Additive also provides an ability to generate complex textures for model surfaces.

We were recently able to see examples of this capability applied to prints made on Photocentric equipment.

As you can see in the image at top, you’ll begin to understand why I’m so excited about this feature. Take a look at the incredibly varied styles of textures and lattices that were produced on this rather large resin 3D print.

Producing lightweight parts is a primary concern in many industries, and the ability to automatically generate an appropriate pattern for a given part could be quite valuable. It also means that Photocentric 3D printer operators could save on materials as the lattices require less material.

The 4D_Additive texture library apparently includes over 5,000 entries, making certain there is something available for every conceivable application.

This partnership between the parties is an interesting move by Photocentric, as it provides another “sticky” factor for their equipment. I find this fascinating because long ago their entry as a 3D printer manufacturer was a way to make their resin more “sticky” (no pun intended) with clients. Now they are creating layers of stickiness.

Via Photocentric and Coretechnologie