Prusa Research dropped the latest version of their popular 3D print slicing software, PrusaSlicer 2.4, and it has an astounding number of amazing new features.

The open source project has been used to support Prusa Research’s growing line of desktop 3D printers, both FFF and MSLA. It’s also been used to support many third party 3D printers through the use of machine-specific configurations, many of which are actually supported by default in PrusaSlicer.

Thus any changes to this software affect not only Prusa equipment owners, but many others using different 3D printers, too.

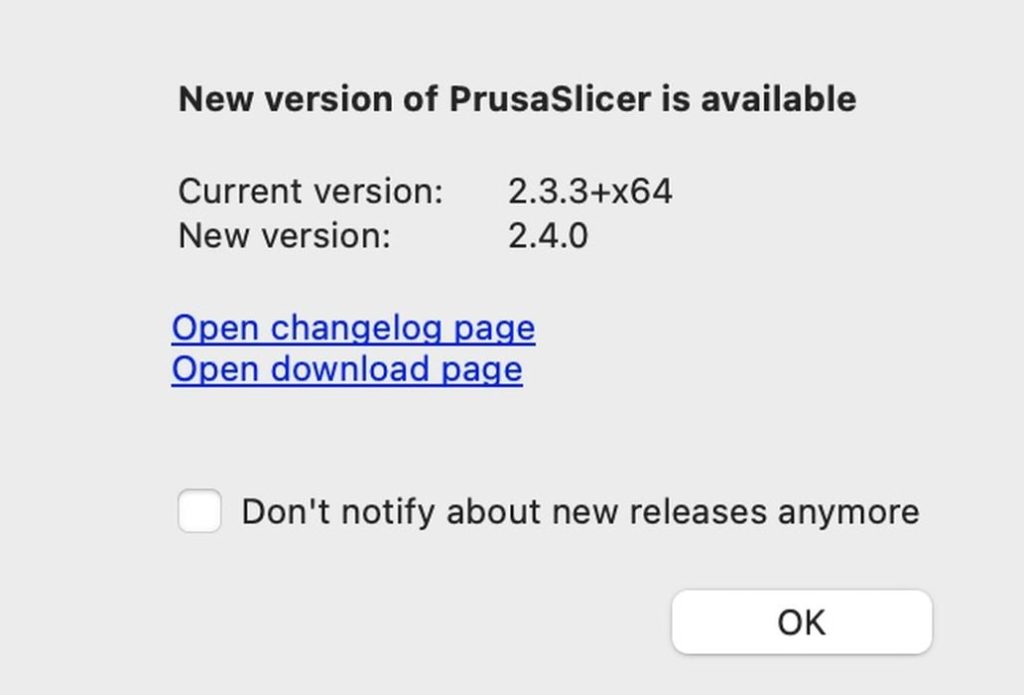

Prusa Research has a hefty team dedicated to working on this software, and it undergoes regular updates. This one upgrades the current production version, 2.3.3 to the new 2.4 version.

Note that they’re changing the second digit in the version number, indicating a significant change, and that’s precisely what’s happened here. The only bigger change will be the change to “3.0”.

There are so many changes in this release it’s difficult to know where to start. I’ll review the key changes I believe will be of most interest to 3D printer operators.

Faster Slicing

Prusa Research has parallelized the slicing process, so when running PrusaSlicer on a multi-core machine, processing times should be quite a bit faster. Prusa Research said you should expect run times 2-4X faster.

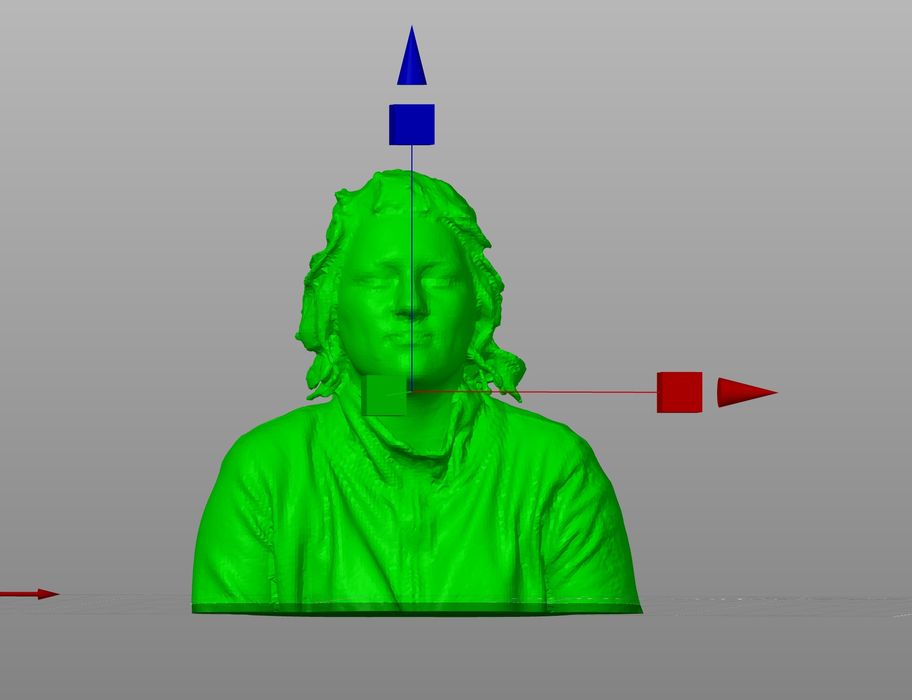

I put this to the test by slicing the enormous 98MB VenusDeMilo 3D model by Cosmo Wenman, which has about 2M triangles. On the older v2.3.3 my slice took about 34 seconds. After the upgrade to v2.4, my runtime was 24 seconds, about 30% faster. This is nowhere near 2X faster, so I’m not sure what’s happening here. I did notice that all cores were used during the slice, so the parallelization did happen. I think more testing is required, and any speed up is quite welcome.

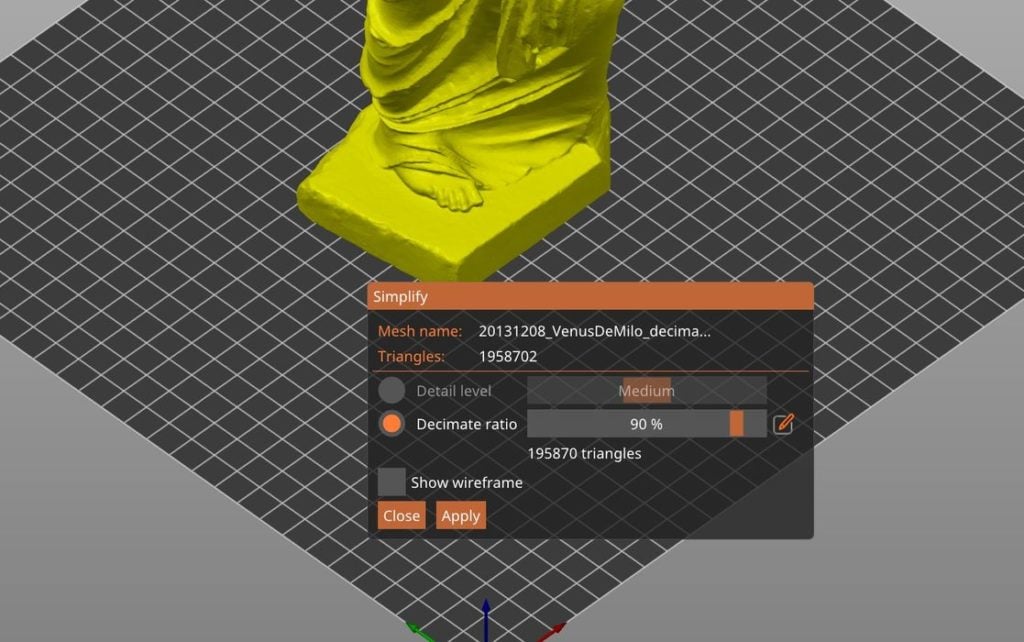

Mesh Simplification

The new v2.4 includes an on board function to simplify 3D meshes, something that would normally be done in an external program, complicating workflows. Mesh simplification is necessary in some cases to speed up slicing, particularly if the detail of the 3D model exceeds the capability of the 3D printer to reproduce those details.

I tested this function again with the Wenman model, and it does work. I reduced the size of this model from 97MB to only 9.8MB in only a few seconds. Interestingly, the slice time of the simplified 3D model went down to only 18.5 seconds, another slight saving in time.

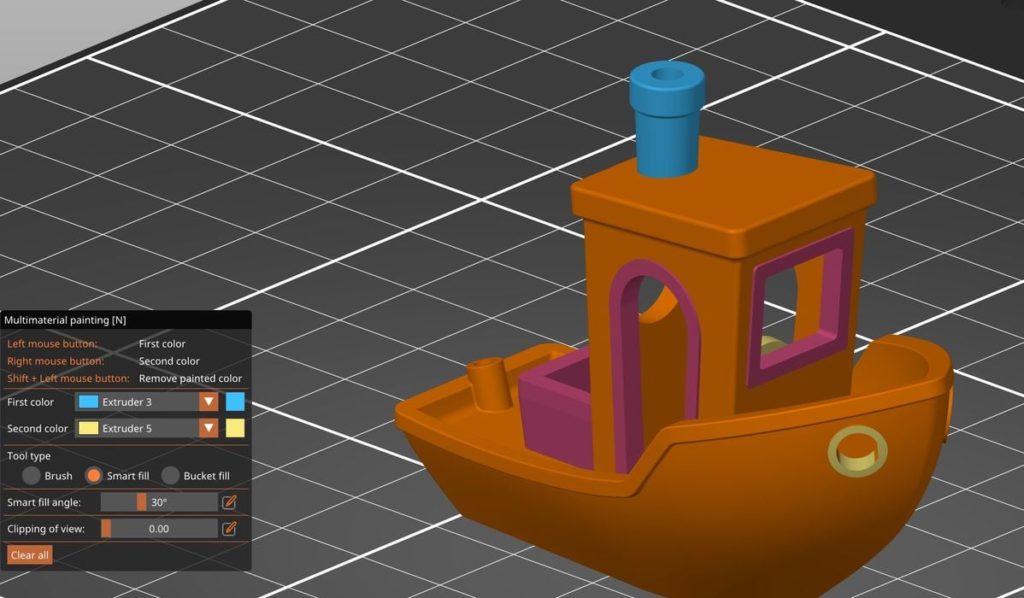

Multi-Material 3D Painting

The biggest new feature in v2.4 is the inclusion of multi-material painting. This allows the user to “paint” sections of a 3D model for multi-material printing. Essentially the model is sectioned, where each section can then be assigned a different color. This permits very easy conversion of mono-color 3D models into color models suitable for production on the company’s MMU2S-equipped devices.

The painting process is quite smart, as it detects edges and “paints” up to those edges. For problematic areas it’s possible to adjust the sensitivity of the painter to capture areas properly.

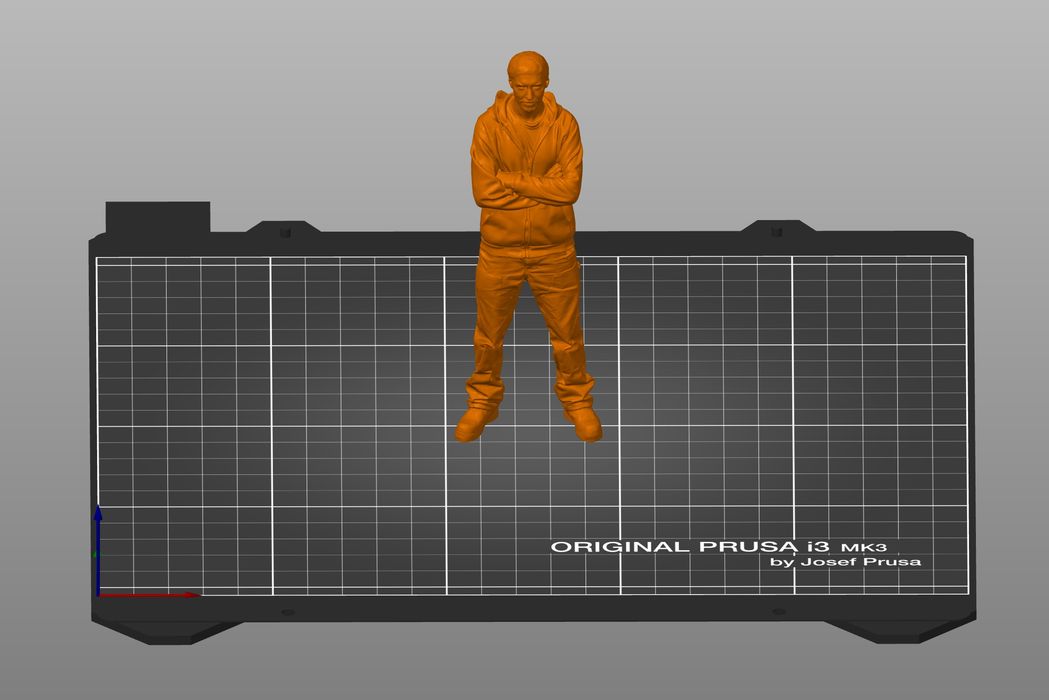

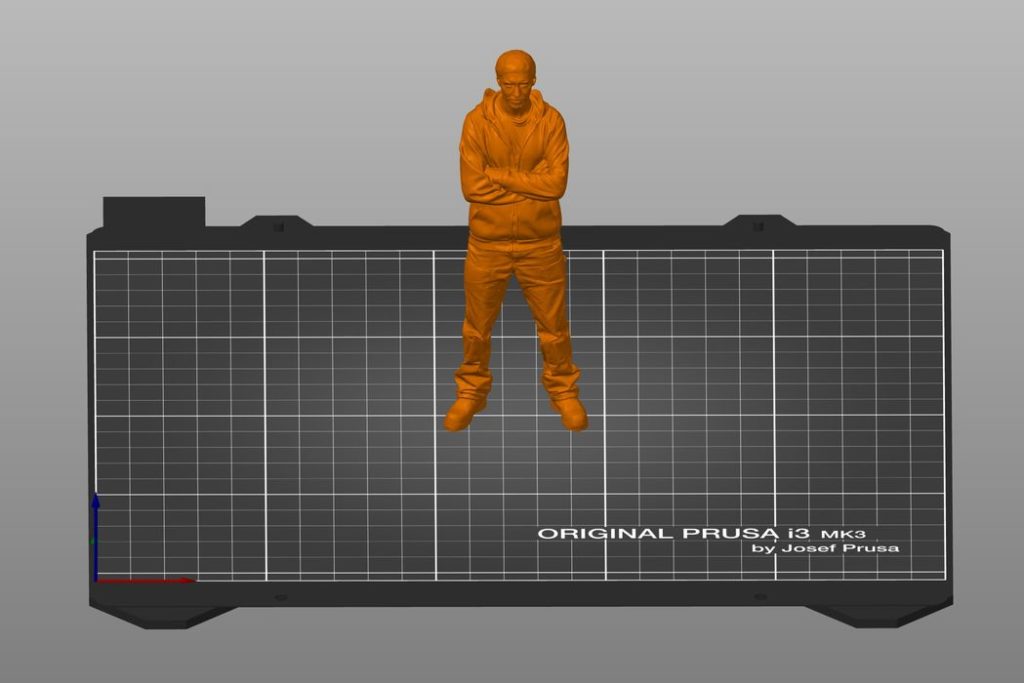

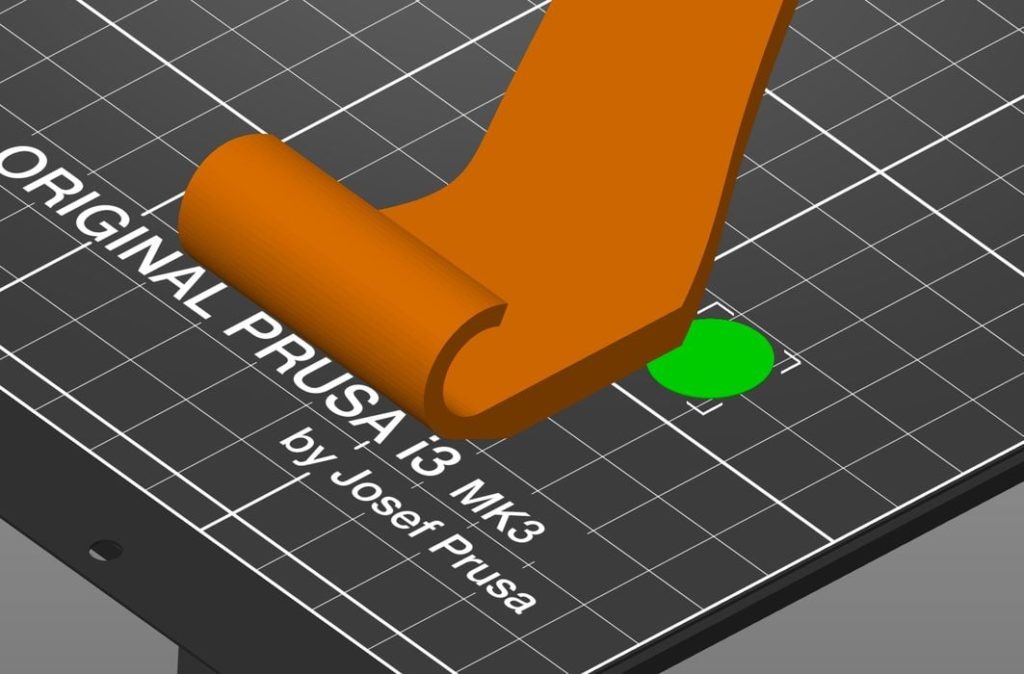

Print Plate Cuts

This is a simple feature, but perhaps one of my favorites.

A very common problem is print failure due to improper bed adhesion. One of the causes of this occurs when a 3D model appears to have a flat bottom, but actually it is not, and only a tiny portion of the model is adheres on the bed.

The solution is to perform a plane cut on the model’s bottom to ensure it’s absolutely flat, and then re-try the job. This always requires using an external tool, complicating workflows.

Now v2.4 includes the ability to push the model slightly down through the build plate, whereupon PrusaSlicer will automatically chop the model flat to the bed. Amazing!

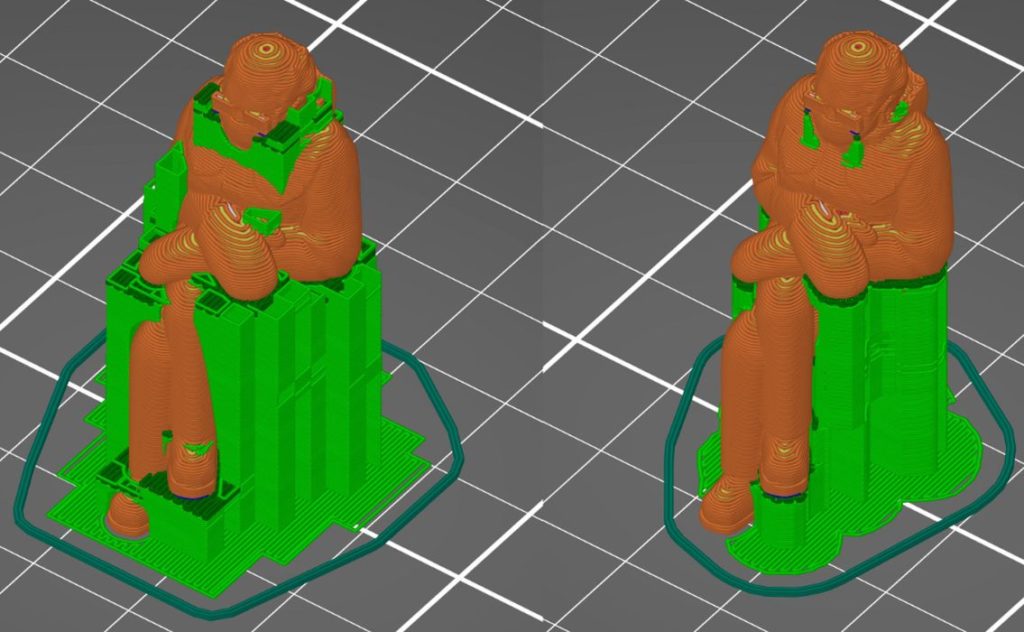

Support Structure Generation

PrusaSlicer v2.4 includes more advanced support structure generation, including a brand new approach they call “Snug”. This seems to take advantage of nearby model structures to vastly simplify the amount and geometry of support structures in an intelligent manner. They definitely do reduce the amount of material required for support, but this varies depending on the geometry of your 3D model.

Shape Gallery and Booleans

A new “Shape Gallery” can hold commonly used 3D models that can be dropped onto the build plate as required. One way to use this would be to add helper discs to the corners of a 3D model to prevent warping, for example.

While this is useful, and particularly so for operators continuously printing from a selection of 3D models, there’s something else that’s very interesting here.

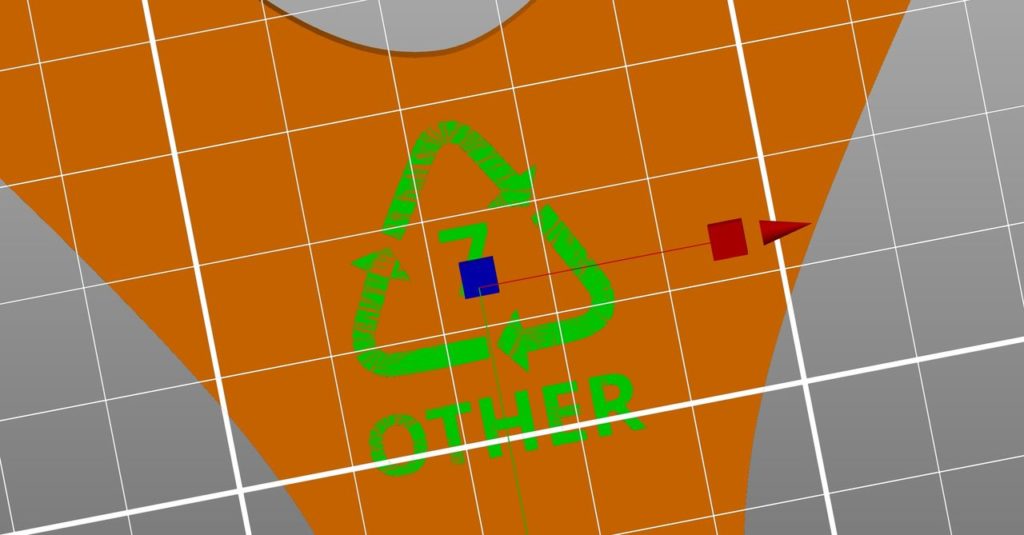

The new software also includes a way to perform subtraction operations on 3D models. For example, you could subtract a cylinder from a model to create a hole. However, this also works with the Shape Gallery, making it possible to create logos and imprints that, for example, could be placed on the bottom of prints for identification. This is a great new feature.

Fuzzy Surfaces!

Some time ago Ultimaker Cura included a function to create wobbly surfaces based on random variations. It seems that the PrusaSlicer team recompiled this open source function for PrusaSlicer, making it possible to easily create these surfaces on 3D models before printing. They suggest it’s a great way to increase the grip factor on handles, and I agree.

Automatic Logo Colors

Suggested by Fabbaloo friend Richard Horne, this feature automatically detects layered 3D models such as logos and suggests pauses to change colors during the print.

This is something I’ve done in the past, and actually it’s pretty tedious to manually figure out which layer to pause the print, particularly if there are several color changes to perform. Now PrusaSlicer does this automatically.

Collision Visualization

It’s long been possible to 3D print objects separately from the entire layer, and that’s very useful to avoid print failures on a large job. However, it could still fail if you placed parts too close to each other, and the print head might knock over a previously printed object.

That won’t happen anymore because v2.4 includes a new visualization that shows the “collision zone” around objects as you move them around the build plate.

MSLA Auto Orientation Choices

For the MSLA system operators, v2.4 includes three new styles for automatic object orientation, a critical step in setting up a resin print job. You can choose to optimize for print time, surface quality or minimizing material use.

GCODE Inspection

Finally, v2.4 includes a way to actually see the generated GCODE while inspecting the print preview. This could be very helpful for setting up new printers on PrusaSlicer, or when there are unexpected problems on a complex 3D print.

Video

Prusa Research has published a video showing some of these features, and I encourage you to view it. You might want to watch a few times to get all the features, as there are so many to consider.

In all, PrusaSlicer 2.4 is an incredible upgrade that you should download immediately. Well done, PrusaSlicer team!

Via PrusaPrinters