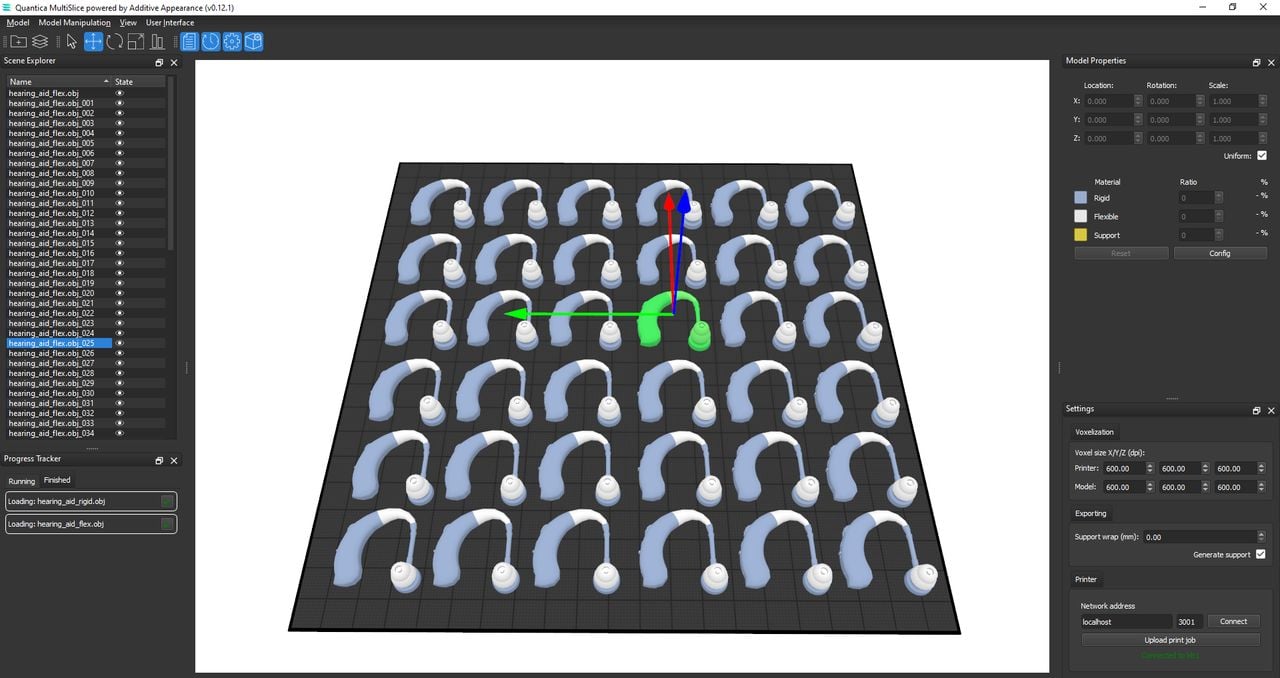

Quantica has introduced a new software tool for their powerful NovoJet 3D printers.

The new software is called “MultiSlice”, and it’s designed to work with the company’s unusual inkjet system, NovoJet. The software was developed in conjunction with Additive Appearance, a Charles University spin-off.

What’s the big deal with NovoJet? At first you may think it’s similar to many other inkjet-based 3D printing systems, where an arm swings over the print surface, selectively depositing drops of material.

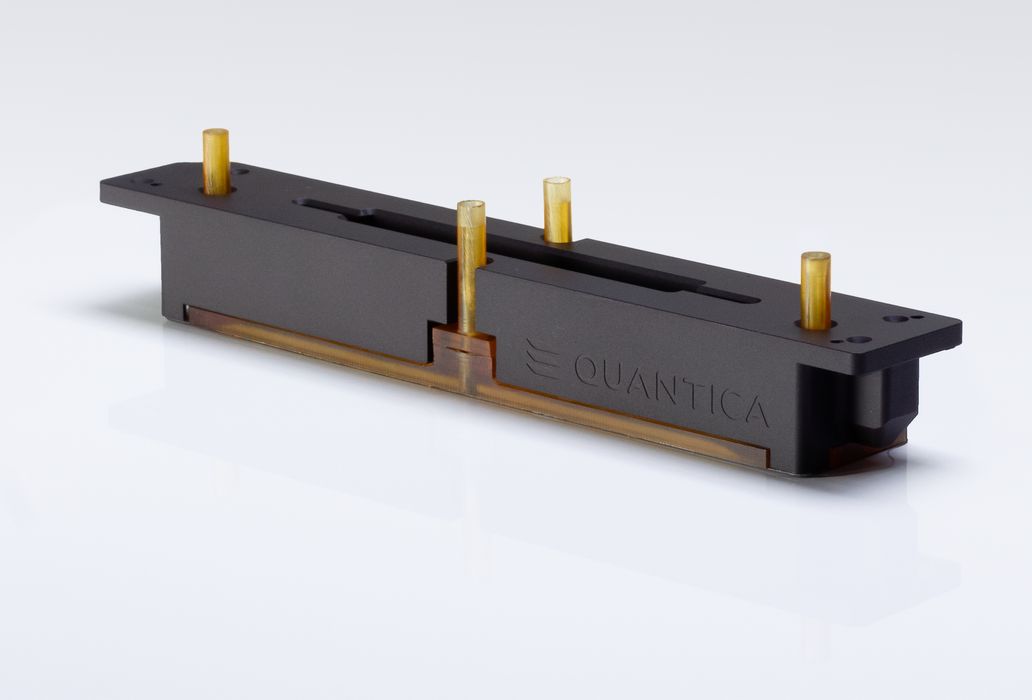

NovoJet does that, but due to some interesting technical magic, the print heads are able to handle vastly more viscous materials. That unlocks the ability to 3D print the widest possible set of engineering materials that are not present on other 3D printing equipment. In addition, the system can handle multiple materials in the same job — controlled at the voxel level.

This is where it gets more interesting: because the process can print in a wide variety of functional materials all at once, it’s then possible to print fully functional end-use objects.

One can imagine relatively complex objects with many parts being produced in a single print job, something that was a dream only a few years ago.

But then there’s a problem: how do you prepare print jobs for such complex 3D prints?

Additive Appearance CTO Tobias Rittig, Ph.D. explained:

“With the trend in 3D printing going to more and more printheads, existing software is starting to limit the hardware’s potential. The problem of which material to put in which voxel is getting increasingly difficult. This is why a radically new approach based on cutting-edge research and modern software technologies, such as differentiable computation and machine learning, is required to drive the printers of the future. We both share this realization and are looking to create a synergy of software and hardware that unlocks many new possibilities in the material-jetting domain.”

And that was the genesis of MultiSlice. Quantica explains:

“MultiSlice embraces disruptive concepts that break away from the traditions of 2D printing, ushering in a new era for the 3D printing industry. Using simulations, it overcomes challenges like the combinatorial problem arising from increased number of printheads and materials. Powered by cutting-edge research in artificial intelligence and differentiable computation, MultiSlice integrates colors, functionality and shape into the final printed part.”

MultiSlice supports input formats of STL and OBJ, and soon will add 3MF.

Above is an example part produced by the system, and you can see how the radically different materials can be used to create a very complex part.

This is a very important step for Quantica, which as stated above, should unlock many opportunities for advanced use of their equipment.

However, enabling the capability is just one step. Another will be to persuade designers to take on the technology to produce highly complex parts. Technology is one thing, change is another.

But that’s one of the bumps in the road when one introduces radically new technology.

Via Quantica