This week’s question is “how would one 3D print a beak for a swan?”

Fabbaloo reader Chris asked:

“Is there a company you know of in the UK who could make a beak for a swan? It was damaged by a dog so has a large chunk missing.”

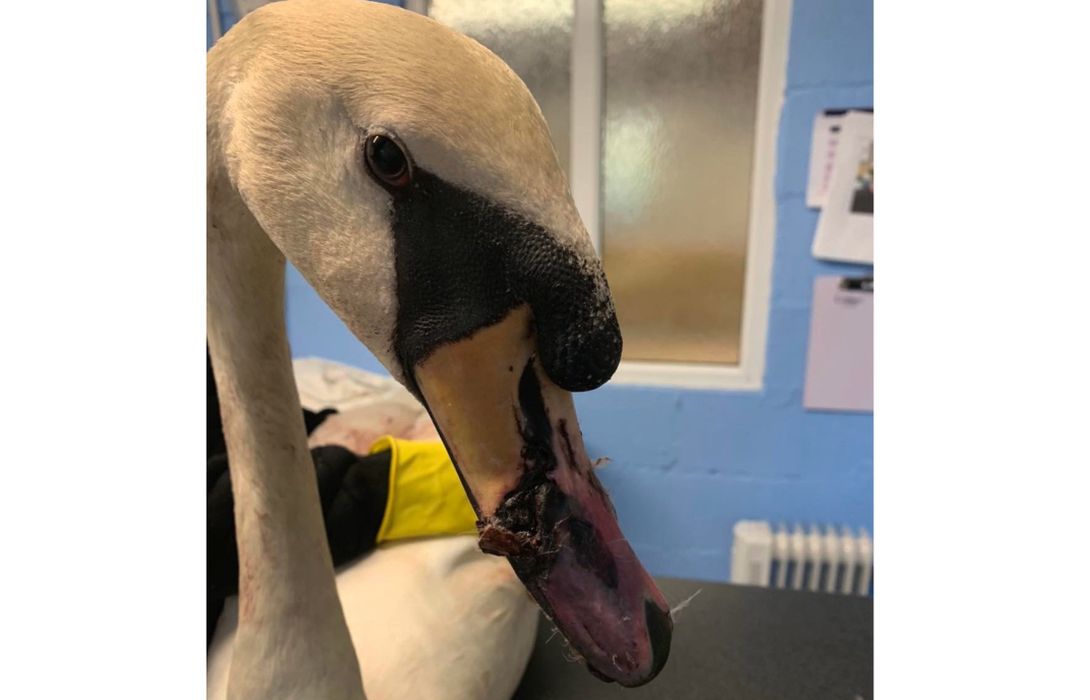

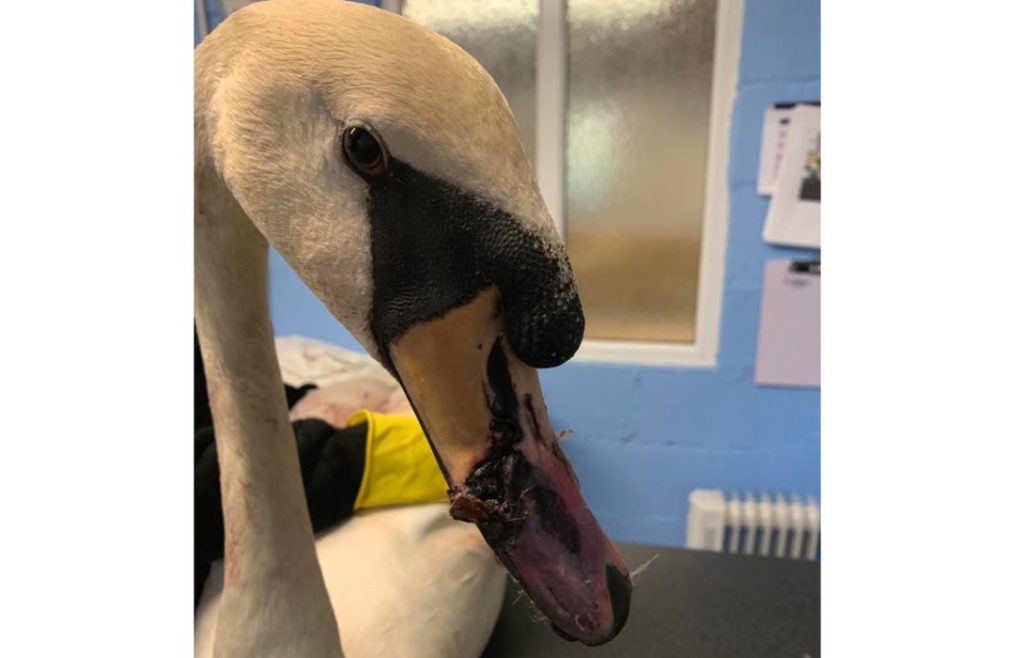

This is a difficult situation, and I contacted Chris to find out more about the situation. Apparently it is taking place at the Swan Sanctuary Millers Pond in south London. In a Facebook post the Swan Sanctuary said:

“This is Wayne from Millers Pond Shirley. He had recently arrived with a lady swan and looked it looked like they might be thinking of setting up home there. Sadly Wayne was attacked by a dog and has suffered a life changing injury to his beak. He now has quite a large piece missing making his top bill unstable and we are closely monitoring the extensive bruising and damage but he is likely to have to stay with us a long time.”

I’m definitely not an expert in such matters, but let me describe what steps I believe would be necessary to perform this replacement.

First, the 3D printing part of this project would be the simplest step of all. What’s far more complex is the veterinary concerns and 3D modeling.

The first step I would take is to engage a veterinarian to answer several questions:

- Is the bird truly affected by this such that a replacement would provide benefit? It sounds like this could be true, but the professionals should make such a decision.

- Would a beak placed on top of the damaged area cause problems in the long term? Would infections be more likely to occur?

- To enable a replacement, would some of the existing mangled beak need to be removed? How would that take place?

- What mechanical properties would be required for a replacement beak?

With all that known, then one could proceed to the next complex step: 3D modeling.

In order to 3D print a replacement beak we must have a precise 3D model of the required structure. Of course, you can’t just download a new beak from Thingiverse and hope it would be appropriate; every bird is different, and in particular the damage to the beak would be only found on Wayne the swan.

The modeling process would likely start with a standard beak design, sized to this particular swan. Then a portion of the beak model would be subtracted to create a surface that would precisely match the remaining beak. Note: this is why we need the veterinarian to determine the state of the current damaged beak; if some is to be removed, then the 3D model has to match.

It’s likely that the existing beak would have to be 3D scanned to properly capture its geometry. This could be then imported into a CAD tool and used to subtract a solid portion from the stock beak 3D model. At that point you’d have a printable and personalized beak for Wayne.

The next step is to 3D print the beak.

Depending on the materials required, it could be done by any number of services or even individuals operating 3D printers. The tricky part here is to determine what material to use. Would a biocompatible material be required? Or not? This is a question for the veterinarian. The choice of material would likely determine the 3D printing process required, and by implication the services that can do so.

The final step is to attach the new beak to Wayne.

I presume this would be accomplished with a highly durable glue that is biocompatible. I’m not familiar with this type of glue, but a veterinarian might be. Application could be challenging, as the glue will require time to set, and Wayne will likely not cooperate. The situation may demand that the bird be restrained a sufficient time for the glue to set before release.

As you can see, this process is not straightforward. There are multiple expert parties required, in addition to someone to coordinate all the activities. It may even be not possible to complete, if the veterinarian’s assessments indicate the risks are not worth the benefits.

I know of no specific service that commercially performs this type of beak replacement. While it has been done by others elsewhere, it is typically a one-time experimental procedure.

All that said, I’m wondering if any readers in the UK are aware of 3D print companies willing to work with the Swan Sanctuary on this specific issue.

Via Facebook