Replique announced public availability of their comprehensive Materials Hub.

Replique is a 3D printing network that accepts customer requests and intelligently routes them to trusted production partners. This is a competitive market with several large players, so it’s important for each competitor to distinguish themselves.

One way that Replique has been doing so is via their Materials Hub.

What’s a Materials Hub and why would you need one? The answer is in the workflow required to 3D print a part.

Typically a requestor uploads a 3D model for printing, and they must specify a few things about the job. These would include the number of units, finishing and most importantly the material to be used.

But what, exactly, is the right material for that job? Normally the selection of materials would be done by an engineer who would sift through a database of materials to select one that meets the engineering requirements for the application. Those requirements might include factors such as the strength, thermal resistance, corrosion resistance, UV properties, medical certifications, etc. There are actually dozens of possible factors that might be required on a given application.

For many applications material must be selected from a reputable provider that provides spec sheets and other data. This helps provide traceability for the part after production.

That’s all good, but what if you aren’t an engineer with a huge database of materials at your disposal?

That’s where Replique’s Materials Hub comes in. It’s a huge and comprehensive database of over 400 different polymers provided by 25 different materials manufacturers.

Replique’s Materials Hub is an easy-to-use viewport into this database, where the user can create complex queries.

You can, for example, specify a number of engineering constraints, and the Materials Hub will sift through the 400 polymers to list the few that actually meet the required criteria.

This is fantastically faster than trolling through the websites of multiple materials companies looking at specs.

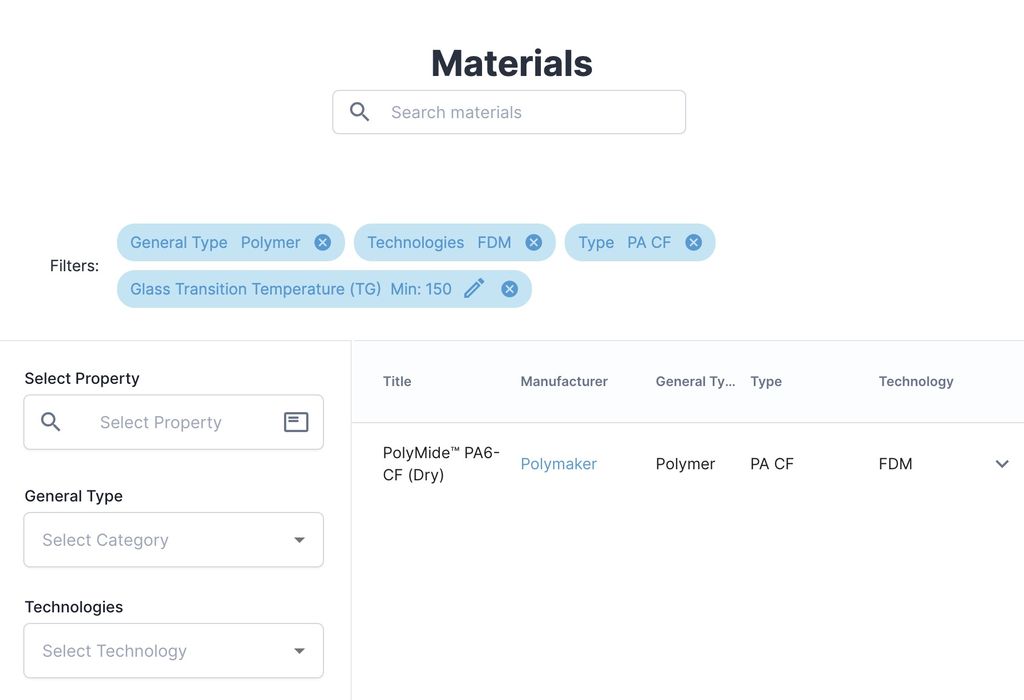

Here’s an example. I tried looking up a “polymer”, used for “FDM”, of type “PA CF” that has a minimum glass transition temperature of “150C”.

As you can see, Materials Hub provided one result (a Polymaker option) from the 400 in their database.

Here’s the best part: ANYONE can use the Materials Hub. You simply need to register on the Replique site and you’ll be taken to the Materials Hub where you can immediately issue database queries.

If you’re looking for a quick way to figure out which materials are best for your project, you might want to check out Replique’s Materials Hub.

Via Replique