Charles R. Goulding and Preeti Sulibhavi examine the potential of 3D printing to aid the process of reshoring the pharma industry.

The pharma industry is highly process-dependent and complex. The task of reshoring the industry to the US is not an easy one and “Making America Pharma Again”, or MAPA as the movement has been referred to, will not happen quickly. Big pharma companies did not establish global operating models overnight, hence the reshoring will take time. Even so, doing it properly is the key to its success.

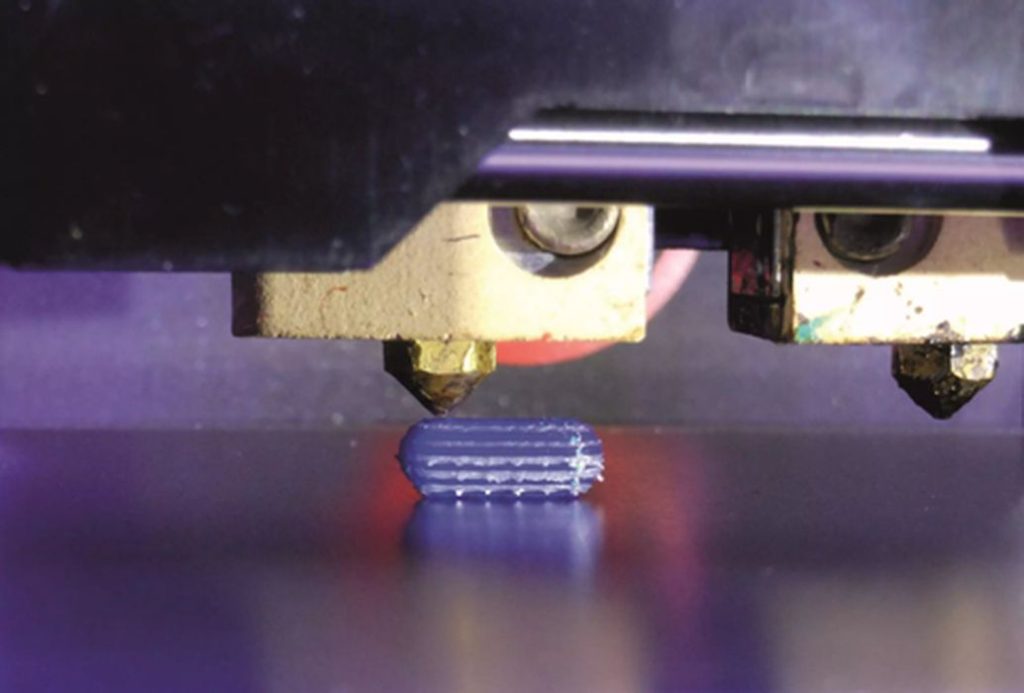

3D Printing and the Pharma Industry

There is a myriad of benefits that 3D printing offers the pharma industry. First, owing to the compact and portable nature of 3D printers, they can more readily be placed in service at US pharmaceutical labs, local community and hospital pharmacy settings. The benefits of having 3D printers onsite include multi-drug 3D printed formulations for seniors who often take multiple tablets at various times of the day and are at risk of confusing some of their medications if not properly monitored.

3D printing tablets can be of help to seniors. Tablets can be customized to help differentiate between nighttime and daytime drugs, with images such as a moon or sun. In addition, tablets can have different shapes to represent different medications or multi-medication tablets.

Children are often reluctant to take medication. Because of that, 3D printers are often used to fabricate tablets with different flavors and colors, they can be chewable and have multiple formulations to reduce medication loads for kids. 3D printing can improve the appearance, taste and texture of tablets to help children be more amenable to taking their medications.

Utilizing 3D printing technology can help make the reshoring process more efficient and cost-effective. Much of the pharma industry is based on patient outcomes for various illnesses. Creating prescriptions that are customized and tailored to certain populations increases treatment efficacy and can improve patient outcomes.

One of the leading companies operating in the pharmaceutical industry is F. Hoffmann-La Roche (Roche). Roche is creating a new, alternative way to screen drug candidates in early stages for efficacy and toxicity. Using 3D cell cultures, microfluids and 3D printers, Roche is cultivating cells from patients and creating organ-on-a-chip technology. This technology could reduce animal testing while still maintaining comparable results. 3D printers are being used to help fabricate the “chips.”

Pharmaceutical packaging is a unique industry that has specific requirements. Aptar is a global packaging giant with heavy pharma packaging expertise. In fact, Aptar utilizes 3D printing to help engineering teams develop new packaging products and concepts before they are committed to steel molds. Aptar has brought 3D printing in-house and finds it is quicker and more cost-effective than outsourcing prototypes to vendors.

The pharma industry includes drug manufacturing, but it also involves lab equipment and pharma packaging components as well. Reshoring the core pharma industry will bring with it the reshoring of lab equipment and the packaging supply chain.

Thermo Fisher Scientific is the world’s leading lab equipment company. It has dedicated vast resources to 3D printing as a part of its materials science research and development. Thermo Fisher is utilizing 3D printing for prototyping equipment made from various materials including polymers, metals, ceramics, and even concrete.

For example, twin-screw compounding (mixing and compounding viscous materials) helps create new polymer printing materials in filament form. Rheometry combined with Raman spectroscopy allows for analysis of both printing material and final product properties. X-ray fluorescence and X-ray diffraction offer an excellent way to examine the quality of powders for metal 3D printing. Thermo Fisher has been extensively experimenting with this new technology.

As major pharma retailers change their business model to more of a medical clinic model the pharma industry may need to change their product delivery model to be more in line with that while meeting the challenge of more robust but sustainable packaging.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There will be multiple factors involved in the successful reshoring of the pharma industry. Once the large domestic supply chain for lab equipment is restored, the pharmaceutical packaging industry will also benefit. 3D printing can be an important part of the entire reshoring process.