There is an incredibly simple way to recycle dirty IPA from resin 3D printing.

Resin 3D printing is becoming a lot more popular, and operators are discovering the messy troubles one must endure when printing. Aside from the toxicity of the resin, there is an IPA issue.

IPA, or isopropyl alcohol, is the standard solvent for cleaning wet resin from freshly completed 3D prints. This resin must be removed because it would otherwise be cured onto the surface during post-print curing stages.

IPA causes the resin to dissolve, leaving a relatively clean print. This is done in a vat of IPA where the print is typically submerged for a time, and sometimes agitated if done in a proper washer system.

Over time the IPA vat will become saturated with resin. IPA is normally clear, but in frequently used wash containers you’ll see a brown or grey fluid: that’s the accumulation of all the dissolved resin. Sometimes it’s so “dirty” that a second “clean” bath of IPA is required to complete the wash.

The bottom line here is that resin operators should expect to deal with a tub of very dirty IPA at some point. There are a couple of options:

Dispose of the noxious IPA at a proper hazardous waste depot

Evaporate the IPA

The latter is an interesting approach: you simply leave the IPA outside in the sun. The IPA gradually evaporates into the air, leaving the resin behind. The UV light from the sun transforms the resin, which is still an active photopolymer, into a sludge and then solid chunks. These solid bits are non-toxic and can be safely disposed of in the usual manner.

But there is another solution that we discovered at our lab: time.

It turns out that if a tub of dirty resin is left undisturbed for lengthy periods (months), then the dissolved resin will gradually settle to the bottom.

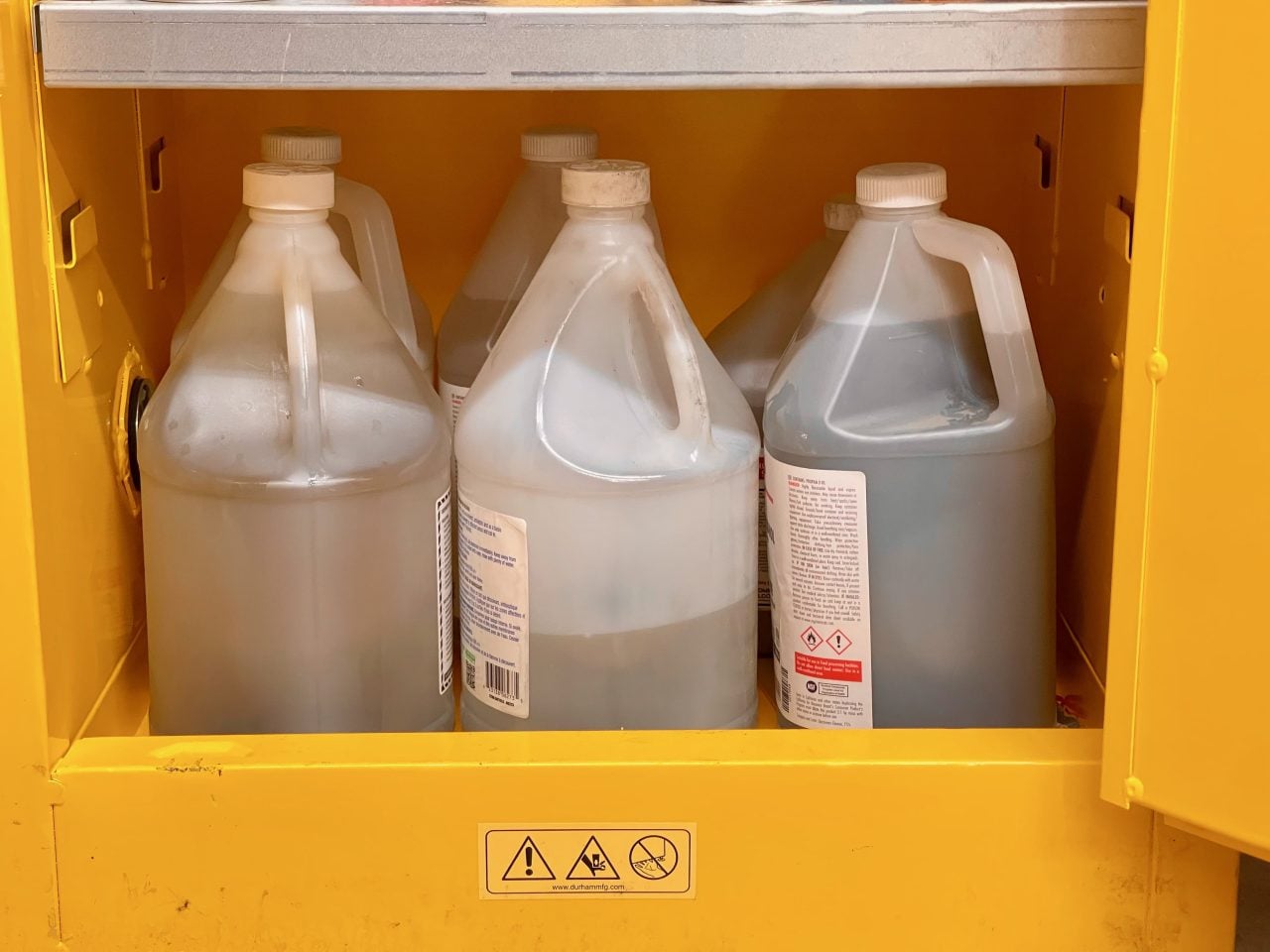

Don’t believe me? Check out these three jugs of dirty resin, each with a different “age”:

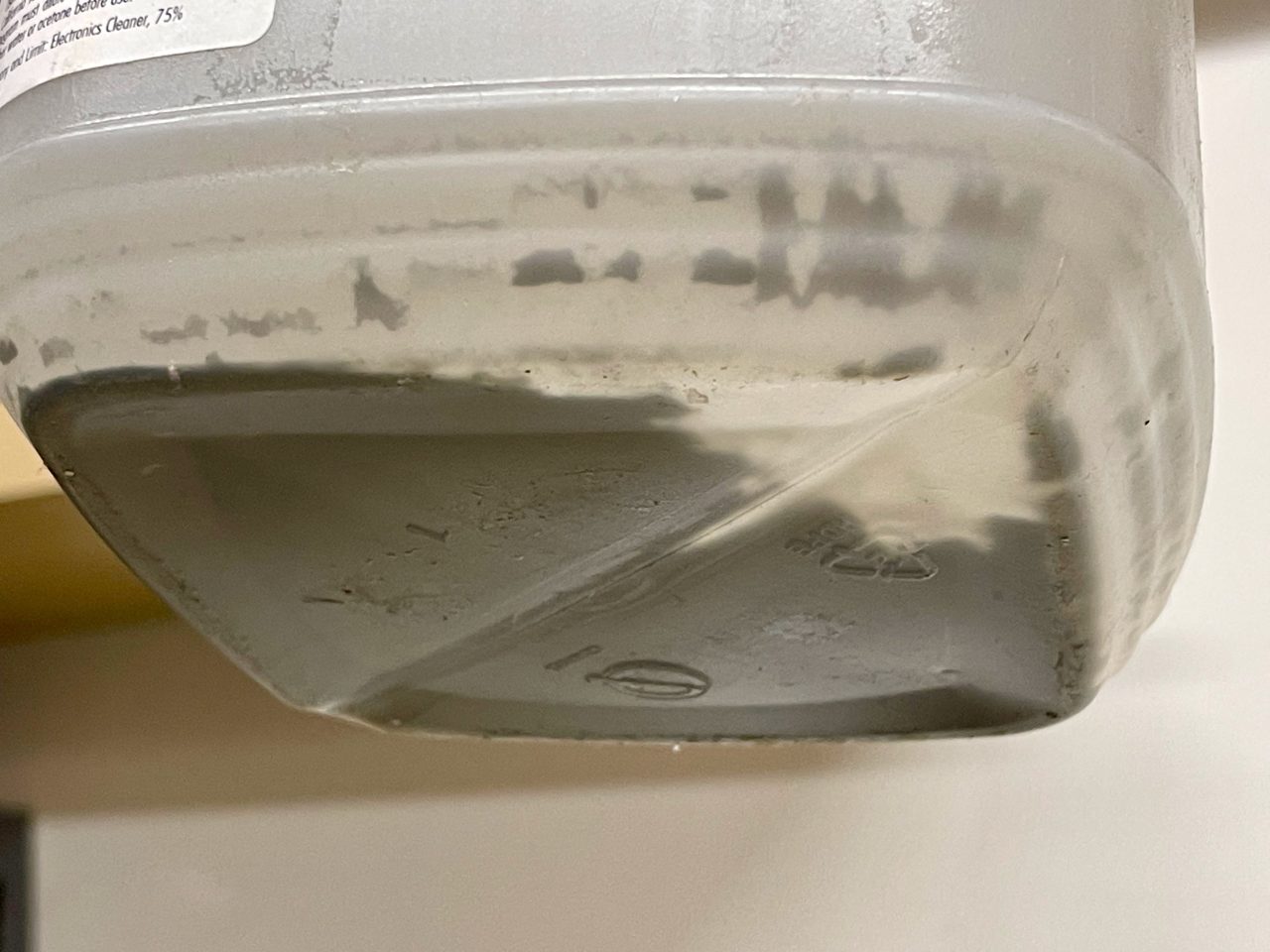

As you can see the resin absolutely settles in the bottom over time. Here you can see the bottom of one of the “clear” jugs, showing resin residue.

After the settling period has completed, it’s possible to simply pour the clean resin back into the washer and use it again. It does not evaporate because the jugs are always sealed.

For safety we keep a rotating series of these jugs in a fire-safe cabinet, as seen at top. When a new jug goes in, the oldest jug comes out and is re-used.

Because of this approach we have not had to purchase IPA for quite a long time.

If you’re operating a resin 3D printer, you might want to get some sealable jugs and try this approach. You could save some money on IPA.

Unfortunately this doesn’t work very well. Only the solids fall to the bottom leaving the IPA more contaminated than is practically useable for cleaning prints. It is ok to use for the first or second bath of a 3 bath system which is good but not great.

I highly recommend looking to your local solvent recycling center, there is definitely one close to you if you live in a large town or city. It is cheap to recycle, please don’t pay for disposal when it can be recycled back to 97-99% IPA at a fraction of the cost!

The painting and paper printing industries have been using it for years, it is not new. Desktop resin printing people, please recycle.

This method allows to remove the resin fillers that are substantialliy insoluble in the IPA. Otherwise resin that IS IPA solubile stays mostly in the surnatant.

To improove this method the flasks with IPA should be exposed to light so that the dissolved resin could polimerize and precipitate. But light exposition should be preferibly be not so massive, to avoid a gelification of the resin in the IPA (and making IPA really difficoult to recover) . So far I’m having decent results exposing the flask to the light from the inside of a window. Glass filters part of UV light and makes the polimerization process mugh slower, ao resin has time to settle or polimerize just on the wall.