Charles R. Goulding and Preeti Sulibhavi look at the life of designer Richard Schultz.

At 95 years of age, Moses Richard Schultz passed away in Princeton, New Jersey. The premier designer was known for his streamlined interior and modern outdoor furniture collections. Considered a design genius by many in the industry, Schultz’s minimalist, clean-lined, and often unconventional work has endured (both the test of time and weather) for decades.

3D Printing and Modern Design

Modern design is not a new concept to 3D printing as we have previously written about artisan designer fabricators and MoMA. But Schultz’s history is remarkably unique. Born in 1926, Richard made steam engines in the family basement, but since math was not his strong suit, he opted for design as opposed to engineering. After the military, Schultz enrolled in the Institute of Design in Chicago, an industrial design school founded by a former Bauhaus professor, Laslo Moholy-Nagy. It was also referred to as the New or American Bauhaus, promoting high-quality design in everyday objects. Such designs are excellent roadmaps for 3D printers to fabricate.

After his education, he was hired on the spot at the Knoll offices in New York City by Florence Knoll on the strength of some design sketches he presented. Since then, Schultz’s form has followed his technique, whether it be a unique outdoor furniture set or home goods (i.e., a vase or a unique lamp or lantern) his good designs were a refreshing addition to any collection.

Schultz had experienced some hardships, but his designs always brought him to where he belonged. Among the avant-garde designers of our time, Schultz has carved an indelible niche into our collective aesthetic psyche.

Much of what Schultz created during his career could have potentially been assisted by 3D printing. While he is no more, his designs live on, and the 3D printing industry can take note of such masterpieces.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

In Memorial

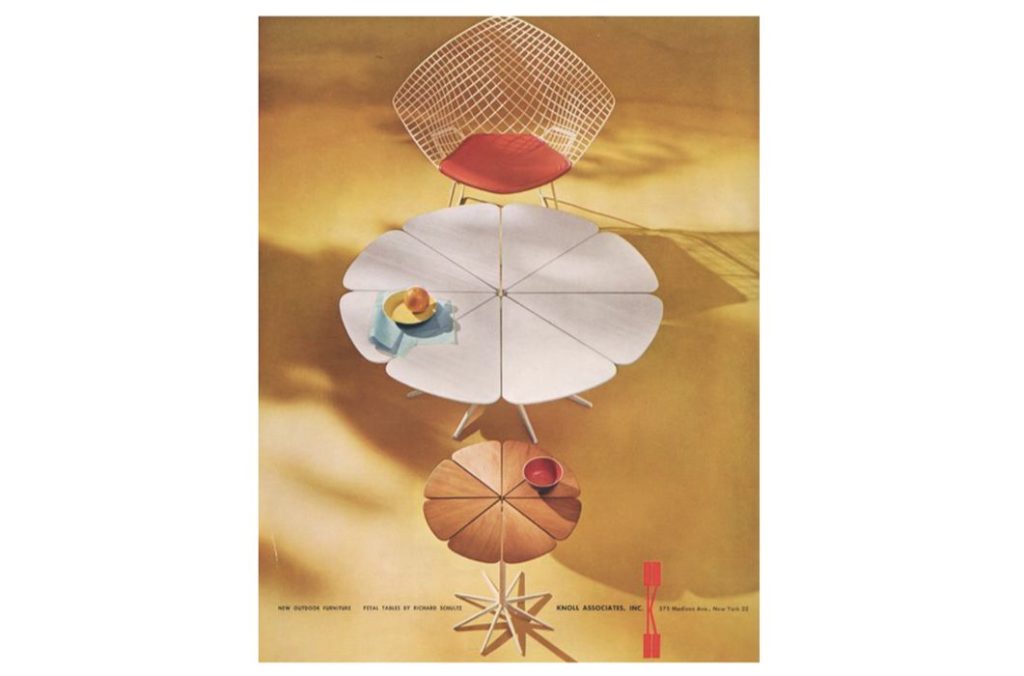

Richard Schultz’ Famous Outdoor Petal Table [Source: Forbes]

They often say, “substance over form.” But Mr. Schultz’s legacy illustrates just how “form follows technique.” Ms. Schulz died in 2016, and their daughter Monica Fadding passed away in 2006. A life well-lived, Schultz is survived by his three sons and four grandchildren.