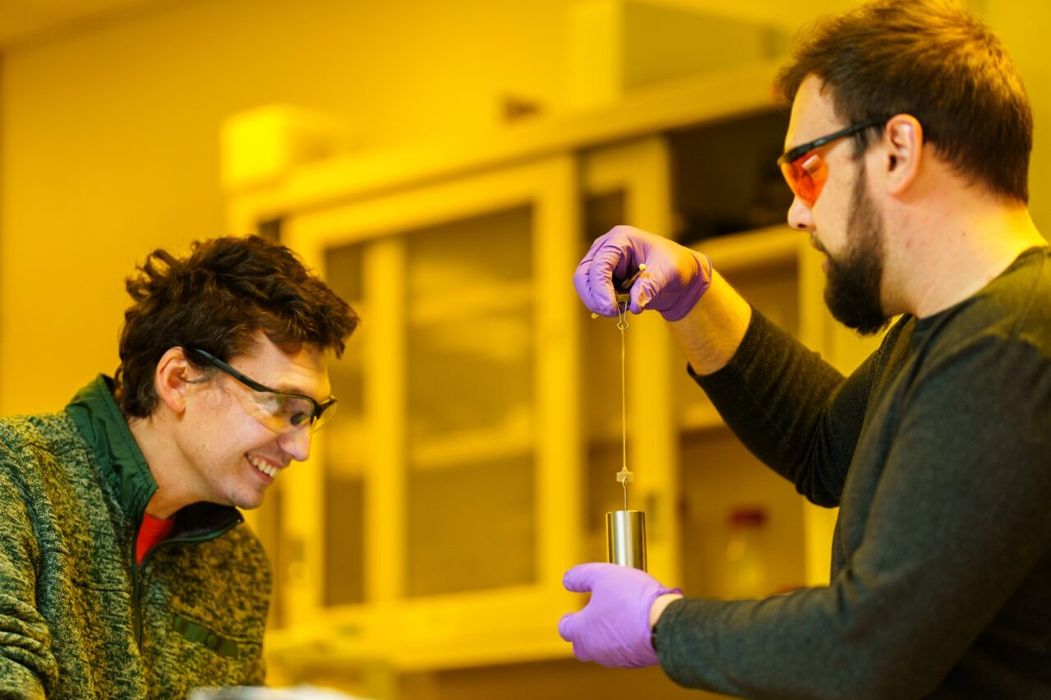

Scientists from Sandia National Laboratories have developed a new resin 3D printing process they call “SWOMP”.

Resin 3D printing is a well known technology in 3D printing, and there are multiple processes that make use of it. The most popular approaches use under-vat illumination to solidify layers, but this approach is often slow.

The issue is that the newly formed layer adheres to the resin tank, requiring a slow “peel it off” stage. Some companies, such as Carbon, have developed proprietary methods to reduce or eliminate the adhesion, leading to faster print speeds.

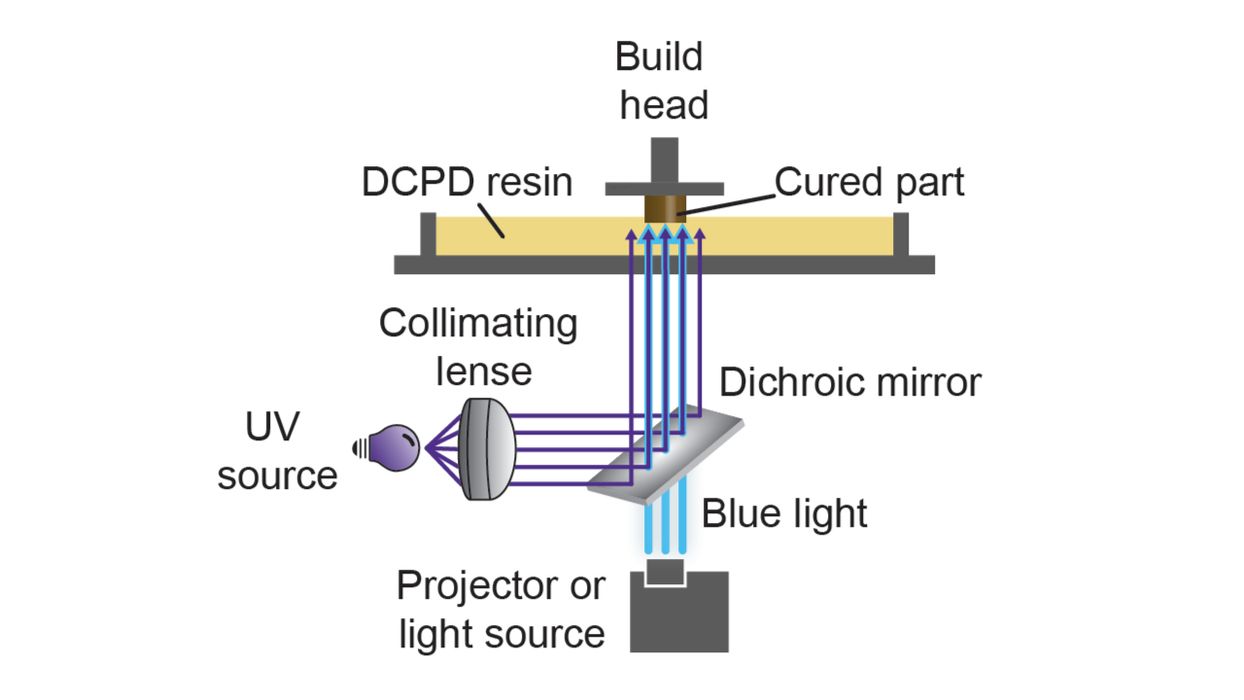

The new research from Sandia describes “SWOMP”, which is an acronym for “Selective Dual-Wavelength Olefin Metathesis 3D Printing”. The “dual wavelength” is one of the two unique features of SWOMP.

What is the dual wavelength used for? In their design one light source polymerizes the resin, as is usually done in 3D printing. The second wavelength — a different frequency — is used to disrupt polymerization near the vat.

This means there is no adhesion of fresh layers to the tank, and no requirement for a slow peeling step for each layer. In other words, this approach can dramatically speed up resin printing, as a huge portion of the job time is devoted to peeling.

That’s not all. The second innovation has to do with the “olefin” in “SWOMP”. Resin 3D printing today is based on acrylics, whereas here the scientists have developed a method to instead use olefin-based resins.

Specifically they used dicyclopentadiene, a common industrial chemical, and found a way to rapidly polymerize it using light, in the same way acrylic resins are polymerized by UV light.

Why do this? Acrylic resins do work, but produce parts that are notoriously brittle and fragile. That makes them unusable for many production applications where stresses and impacts occur.

The new olefin-based chemistry could enable the use of new and far stronger resin materials for 3D printing. That is very good news as resin 3D printing is one of the most efficient and highest quality processes.

These developments are certain to be commercialized, as Sandia National Laboratories are already offering licensing opportunities for the technology. We may see high speed olefin-based 3D printers emerge in the very near future.