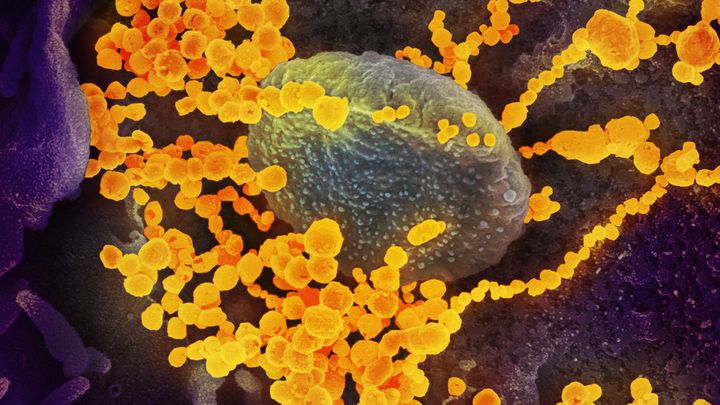

Researchers have developed new polymers that can automatically disinfect themselves, including for SARS-CoV-2.

As the pandemic continues, all efforts are being made to develop and implement ways to reduce its devastation. An enormous amount of research has taken place in this area, yielding many amazing new developments.

One more to add to the list is the work done by researchers at North Carolina State University, who have apparently developed a polymer mix that can disinfect itself automatically.

“Sterilizing” 3D printer materials have been around for some time now, and they work by mixing in substances that degrade microbes on contact. When the microscopic critters encounter materials like, for example, copper, they quickly degrade.

So what’s different with this work? It seems they’ve made a self-sterilizing polymer that doesn’t require the use of metals.

The new material works by including anionic polymers that silently absorb water vapor from the air, which then releases protons through nano-channels to the surface. This creates a super-acid surface coating that is what destroys the offending microbes.

The researchers say they have demonstrated the complete destruction of SARS-CoV-2 in only five minutes, and also tested another human coronavirus at 20 minutes.

The availability of this material would allow 3D printer operators to produce objects that self-sterilize. This would be far less expensive than using pure metal approaches, such as has been done by SPEE3D.

While we know now that COVID-19 spreads mainly by air transmission, there is still the possibility of contracting the virus through touch. An infected party might, say, open a door. The next person to touch the same doorknob might then touch their face and contract the virus.

By producing parts that self-sterilize, this effect could be minimized. While the sterilization could take some minutes to succeed, that’s a heck of a lot better than having a virus live happily on surfaces for potentially days, according to some research.

Even after the pandemic, use of this new material on any frequently touched parts would be advisable to reduce disease transmission of any type. One idea for usage could be shopping cart handles.

If this new type of material turns out to be inexpensive, then there is the possibility of its use becoming a de facto standard in industry. Why wouldn’t we want ALL parts we interact with self-sterilizing?

And if that’s the case, then I can see this becoming a popular 3D print material, too.