Charles R. Goulding and Preeti Sulibhavi believe part of Siemen’s recent turnaround could be due to 3D print technology.

Siemens, the Munich, Germany-based, industry giant has become a top stock market leader headquartered in Germany, defying all odds, particularly those of fund managers and investors. A February 9, 2023, Financial Times (FT) article covered how Siemens has steadied its ailing finances in the past five years to report its highest profit in 15 years in the beginning of 2023.

Part of Siemens strategy, as we have reported includes divesting certain major business segments, including, Siemens Healthineers, Siemens – Gamesa, and Siemens Mobility. The restructuring has clearly resulted in real dollar value for its shareholders.

But what the article didn’t say exactly, and what we are going to discuss, is that not only is Siemens leading a stock market in Germany, but it is also a 3D printing leader throughout Europe.

The FT article indicated that:

“Over the past 20 years, Siemens has created the largest amount of shareholder value among all of Germany’s listed companies, according to a study published last month by the research arm of German asset manager Flossbach von Storch.”

Its financial success is backed by its innovative developments in 3D printing as well.

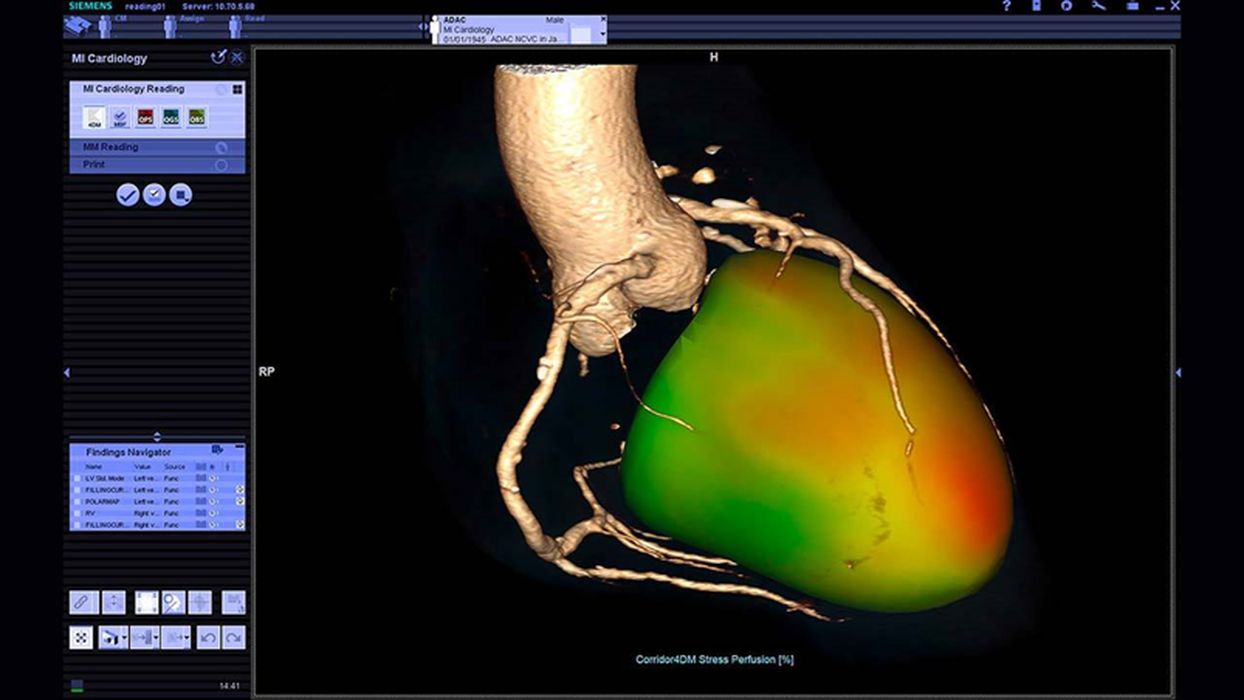

Siemens Healthineers

We have covered how Siemens Healthineers is changing the way med-tech is utilizing 3D printing today. With its US$16.4B acquisition of Varian Medical Technologies, the resources for integrating 3D printing into its innovative, life-saving products has substantially increased.

Just last year, Siemens Healthineers and Materialise partnered to bring 3D printing capabilities to hospitals around the globe. Specifically, Mimics inPrint, a software necessary to make anatomical models using patient specifications, will allow radiologists to turn a patient’s body scan data into a digital 3D printable model. The software will be available as an app that will provide physicians an added dimension to medical imaging and help save lives.

Siemens – Gamesa

Gamesa its energy business is the leading global wind power business. Specifically, Siemens-Gamesa’s turbine business has been integrating 3D printing technology into its operations. In recent years, Siemens-Gamesa has produced gas turbine blades using 3D printing technology using high-performing polycrystalline nickel superalloy this was produced by Materials Solutions, a British 3D printing company.

Siemens Gamesa has created a recyclable blade for both offshore and onshore use. The company is committed to producing 100% recyclable turbines by 2040.

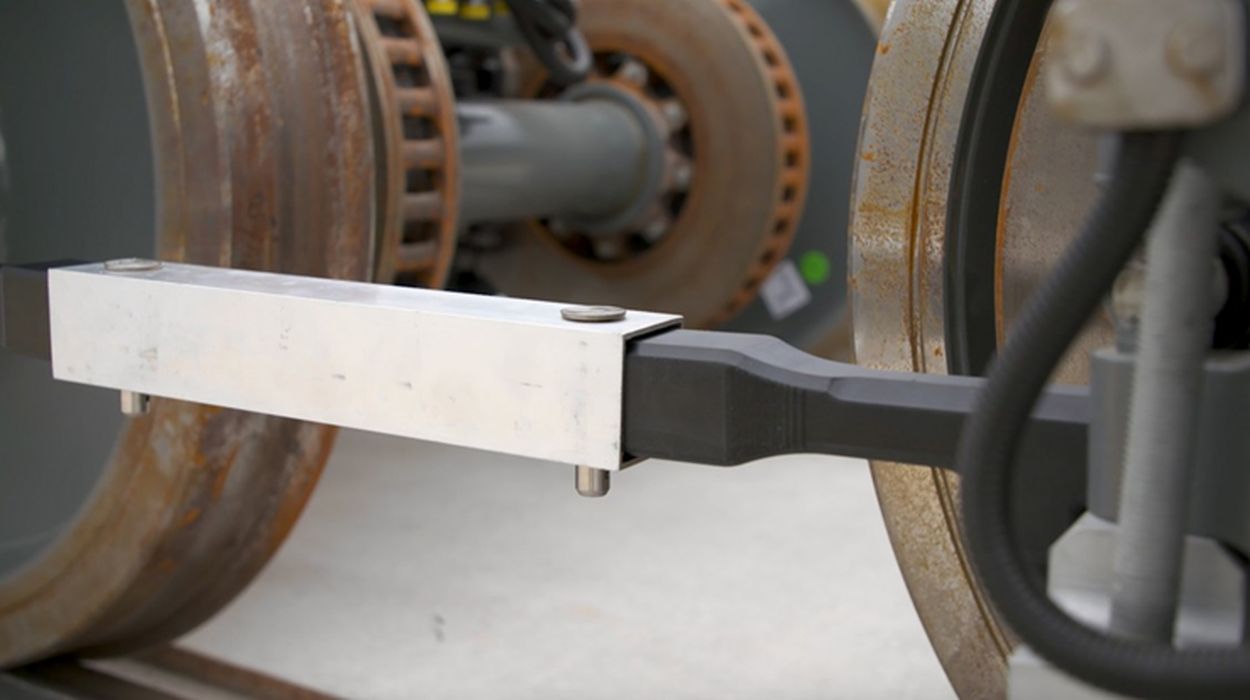

Siemens Mobility

We have recently covered the new US$3.25B rail contract with India, but Siemens mobility goes beyond that. It has created value by utilizing 3D printing technology for rail replacement parts and to repair components in a timely and cost-effective manner. We have covered how 3D printing can impact the railway industry in our Fabbaloo piece describing the “Ukrzaliznytsia” (Ukraine’s extensive railway) as well as The US Railway Labor Deal. Wabtec’s contributions to the Freight Rail Research Institute are notable as well, which includes the program developing zero-emission locomotives.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

It is no small feat to defy all odds and turn an underperforming conglomerate into a lean, efficient, profitable company. Much of the credit has gone to Roland Busch but Siemens has also benefited from its continuous utilization of 3D printing technology.