Stratasys announced the J5 MediJet 3D printer, targeted at the healthcare market.

The J5 MediJet seems to be an adaptation of their popular J55 general purpose 3D printer, with modifications to ensure prints are biocompatible. The parts printed are also sterilizable.

Like the J55, the new J5 MediJet 3D printer sports an unusual rotating build platform, something I’ve seen on only a few 3D printers. This approach is quite compatible with the company’s PolyJet system, where inkjets selectively drop material as the bed rotates under them. Each layer will undergo a UV-light treatment to solidify the liquid material before proceeding to the next layer.

What exactly can you make with the J5 MediJet? It turns out this is the key to the product, as its technology allows many different possibilities, yet all within a specific vertical market: healthcare.

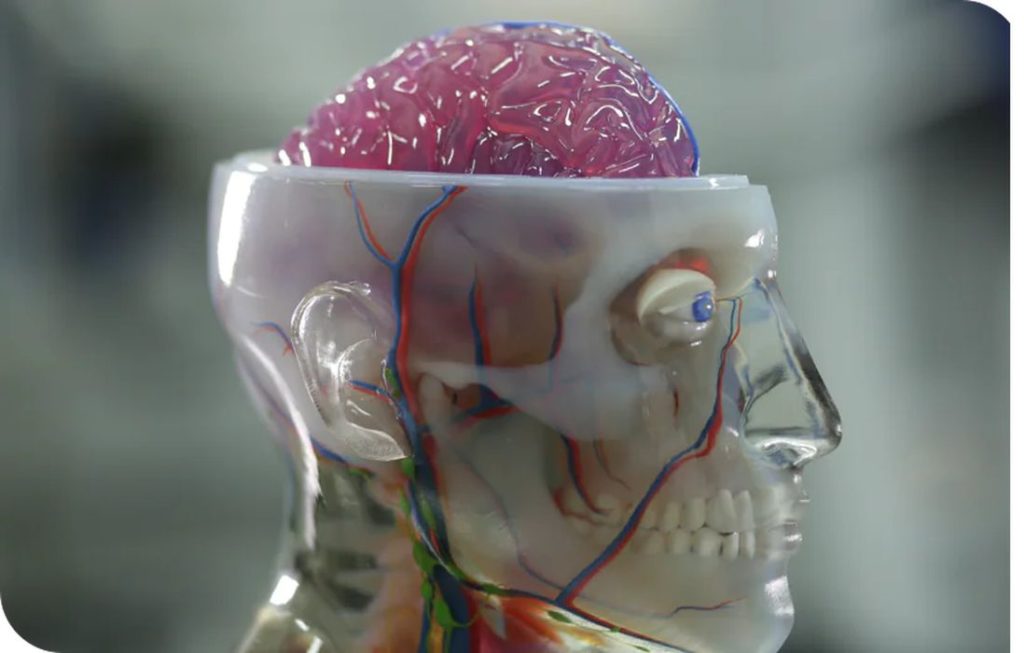

The J5 MediJet is capable of multi-color and multi-material 3D printing and is also biocompatible, opening up many options. Stratasys suggests the following applications:

- Anatomical models for educational purposes can be produced using the multi-color 3D printing and multi-material features

- Drilling and cutting guides using the biocompatibility features

- Medical device development

- Pre-surgical planning 3D models

I should point out that for official medical use there are a number of regulatory certifications required, and achieving this is a bit more complex than you might think.

In order to produce truly certified parts, particularly the cutting guides, several links in the chain must be done:

- The 3D printer must be certified, and the J5 MediJet is appropriately certified

- The materials used in the print job must be certified

- The software used to produce the 3D models being printed must also be certified

Stratasys has organized all these to synch up.

For example, the materials for the J5 MediJet include Biocompatible rigid transparent, Opaque, the multi-color VERO line, Elastico Clear, and a new DraftWhite material that’s said to be lower cost.

They can also recommend third party software to be used for these applications that is compliant with ISO 13485 and 510(K) regulations.

When looking at this 3D printer as a whole system, Stratasys is clearly targeting the mid-size healthcare market. These are organizations that are not sufficiently massive to operation fleets of 3D printers, yet are able enough to afford a good-sized 3D printer for general operations.

The idea here is that these organizations would acquire a J5 MediJet and use it for multiple purposes. This is quite different from the healthcare norm, where regulations, processes and device constraints tend to make devices single purpose. Here a healthcare organization could acquire one device and knock off several needs at once.

The other interesting aspect to this announcement is that it is in the healthcare sector, an area where Stratasys’ competitor, 3D Systems, has been growing rapidly. It may be that Stratasys is offering that company some additional competition in that market with the J5 MediJet.

Via Stratasys