Could everyone please get together and figure out a way to standardize 3D printer profiles? Please!

The Wonder of Print Profiles

Print profiles are truly a wonder in 3D printing. Prior to their invention, everyone was basically on their own, struggling with which parameters should be set for their particular print job. Individual settings were shared among friends inside obscure online forums. It wasn’t pretty or effective.

Then someone invented the idea of saving settings in a “profile,” which linked a specific material to a specific 3D printer. If one used that 3D printer with that material using that profile, there was a pretty good chance the print would succeed.

The number of available profiles then grew, and sometimes they were built directly into slicing software, negating the need for hunting around for the desired settings. At the least, one could pick a profile that was “close” and then tweak it to perfection. It was also possible to export the profile after development so that it could be shared and imported by others on their software.

The Interoperability Problem

But there’s a problem, and it affects myself and others every day: interoperability.

Today there are three key worlds of 3D printer profiles:

- PrusaSlicer and its derivatives

- UltiMaker Cura and its derivatives

- Simplify3D

There are certainly other slicers, but most of the profile activity seems centered on the three above due to their widespread use. While I’m speaking mainly about the FFF world here, there are similar issues in the Resin 3D printing world as well, except with different software tools.

UltiMaker, in particular, has gone deep on profiles, having partnered with a number of materials providers and making it relatively easy to add profiles.

The problem, however, is interoperability. Here we often receive 3D printers from various manufacturers for testing and evaluation (which you’ll see in our frequent Hands-On reviews). These 3D printers (usually) come with a memory stick containing either an outdated version of UltiMaker Cura or PrusaSlicer, with some profiles for the machine. Sometimes there are Simplify3D profiles.

Because of this, I find myself constantly switching between PrusaSlicer, UltiMaker Cura, and Simplify3D.

The Call for a Unified System

I don’t want to do that. I want to use one system — and at this point, I really don’t care which — so that I don’t have to keep remembering “how to do that” in the other tool.

Well, you ask, why don’t you just export the profile from one slicer and import it into the other?

Haha, I laugh. That’s impossible. They have different file formats and definitions. It’s apparently impossible to do this transfer — even though it is entirely possible to make usable profiles for the same machine with the same material on all the software tools!

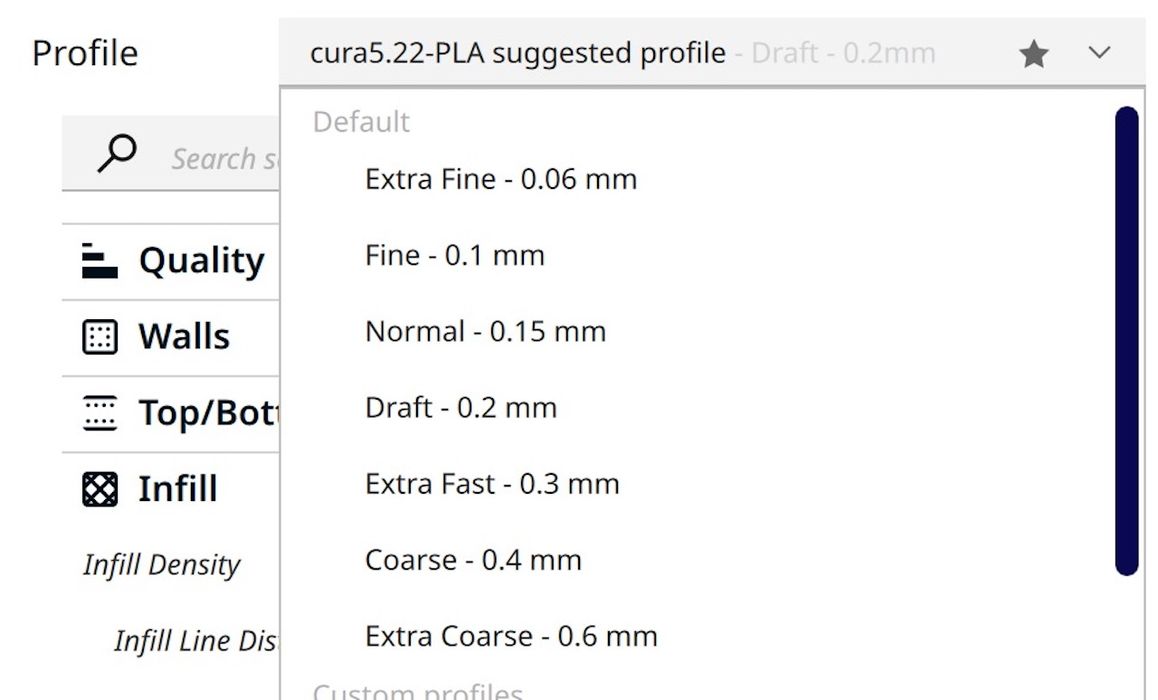

Sometimes this happens even within the tools themselves. Changes in UltiMaker Cura have made it challenging to import old Cura profiles successfully, for example. There’s also the complication of the default settings shown at the top: Draft, Fine, etc. If your old profile is matched with a definition that isn’t present on the new machine, you cannot import it, even though the vast majority of the individual settings are useful.

I cannot tell you how many times I end up opening up a new, blank profile and laboriously typing in settings, one by one, in hopes of creating a useful profile on the “other” slicing software.

A Potential Solution

This should not happen. It’s a waste of everyone’s time and a problem that is entirely solvable.

The answer would be to create a standard profile definition in XML that all slicing software accepts. This would enable exporting and importing freely from anywhere to anywhere.

The Challenge of Implementation

Will this happen? I’m afraid I’m not very optimistic, because the slicing software makers all want to retain their user base. A key way to do that is to make the product “sticky” by having a powerful and closed database of profiles. Allowing easy export might mean another software tool could import them and gain the benefit of that data.

That’s all I have to say about this, and I must get back to profile tweaking now.