Additive manufacturing has increased its ROI by becoming a go-to work-around for supply chain challenges.

There is no doubt that the COVID-19 pandemic has changed the way many companies do business. From workforce challenges to supply chain woes, the pandemic has made apparent the gaps in our current systems and markets. In fact, according to the Supply Chain Resilience Report, 75 percent of U.S. companies “have experienced external disruptions to their manufacturing supply chain in the past year.”

When the pandemic first hit, many engineering and manufacturing companies quickly discovered how delicate their supply chains actually were. While some organizations continue to struggle, others have found relief by looking to 3D printing.

Most of us are well aware of the capabilities of additive manufacturing. There have been many articles written about the changes that this technology can usher in. But many of us are just as aware of its limitations.

Dale Ford, founder and CEO of Hawk Ridge Systems, a reseller of HP and Markforged 3D printers, as well as SOLIDWORKS and other engineering solutions, said, “I think the pandemic has really shone a light on what additive can do.” Hawk Ridge Systems has seen lots of growth in its 3D printer sales over the past two years, driven by supply chain issues.

“The technology has really been democratized down to a point where people can actually take advantage of it in their processes, whatever that is. The supply chain challenges that we’ve seen clients deal with have really helped them recognize the need to take control of their supply chain. That’s what additive has done for a lot of people—they’ve been able to make things local, and not have to be so dependent on outside sources.”

Solving Supply Chain Woes

Hawk Ridge Systems has several different customers that experienced supply chain challenges. And whether that meant late shipments or missing components, it left companies looking for remedies with other suppliers and/or new methods of manufacturing.

“I would argue that most of our customers that have been impacted definitely have a plan B in place now,” Ford explained. “They’re still looking to their traditional supply chain options, but they’re realizing that they need an alternative now, and they’re making that part of the strategy going forward.”

In this sense, 3D printing hasn’t replaced traditional manufacturing strategies, but it has certainly become a reliable resource in a pinch. Many businesses that wouldn’t have considered additive manufacturing have found the process to be a reliable alternative, if necessary.

“I would also say, we talked to as many companies that don’t have supply chain problems as those that do. Those that haven’t had these issues have actually taken advantage of additive. They were implementing additive strategies before the pandemic or were in the process of doing it during the pandemic, and they just accelerated their investments in 3D printing.”

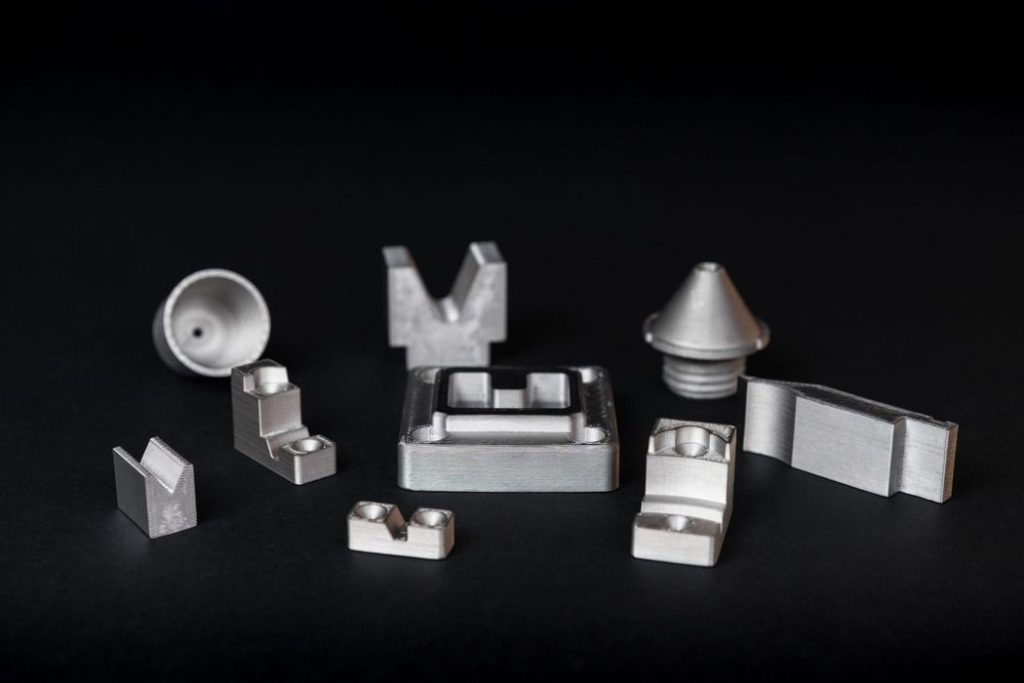

Ford explores what many have discussed—will 3D printing take over manufacturing? In short, not any time soon, but he sees a hybrid model emerging. He explains that the setup for parts is “pretty significant” when it comes to printing with materials like metal. “The types of metal you can print off of one printer right now is pretty phenomenal, but I think things from the true production perspective are still coming.”

Where Ford sees the real value in 3D printing—metal or otherwise—comes in a supplemental form and this newly realized value in adding a buffer to the supply chain.

“There are things that you can make that enable the manufacturing process. Maybe not necessarily the actual finished good itself. But, on the plastic side of things, on machines like HP’s Multi Jet Fusion (MJF) and applications and materials now available—that’s a production chain. That is a viable solution that is offloading traditional supply chain challenges.”

Read more at ENGINEERING.com