SPONSORED CONTENT

What are the giveaways that tell you a company is “smart”?

I’ve seen — and worked in — many different companies from large to small, from ancient to brand new startups. After a while you get a feeling for how a company might fare, based on observations of how it’s managed.

One sign that I often watch for is spending efficiency. It’s tremendously easy for managers to spend more money, but much, much harder to not spend money. The ability to properly manage spending is one of the most important success factors for any company.

Managers must make decisions about how and when to spend, as each dollar should theoretically lead to a return, sooner or later. The best decisions are certainly those that result in less or even no spending: adapting a process or design to reduce or eliminate spending and maximize efficiency.

Decades ago it was the custom to present a wealthy image to prospective clients. This, I believe, was started by banks and insurance companies that wanted to reassure their clients that they “had the cash” to survive and therefore their clients’ money, investments or policies would be safe.

For the financial industry such actions make a great deal of sense. But in other areas it really doesn’t. To me, a telltale sign of good management is efficiency. A 3D printing company that’s spending wildly makes me quite suspicious, and I’ve seen a few operations in our industry do exactly that over the years. Gold-plated offices make me a bit nervous.

Last year our team had the opportunity to tour FAME 3D’s North Dakota factory where we were able to see the company produce their well-regarded LulzBot 3D printers in person. As usual, I observed their operations with an eye for efficiency.

And I found it, almost everywhere I looked.

While some companies might construct a specially-architected oversize building designed for manufacturing, the folks at FAME 3D simply repurposed an existing building at lower cost. It’s not the prettiest building, but it is totally functional for 3D printer manufacturing, with plenty of room for expansion.

Inside we saw countless examples of efficiency throughout the LulzBot factory.

At every turn we observed test rigs, assembly jigs & fixtures, each designed on site to simplify the process of manufacturing. Many of these were partially or entirely 3D printed, using the company’s own equipment for added savings. My impression was that they constantly improve these as new process discoveries are made.

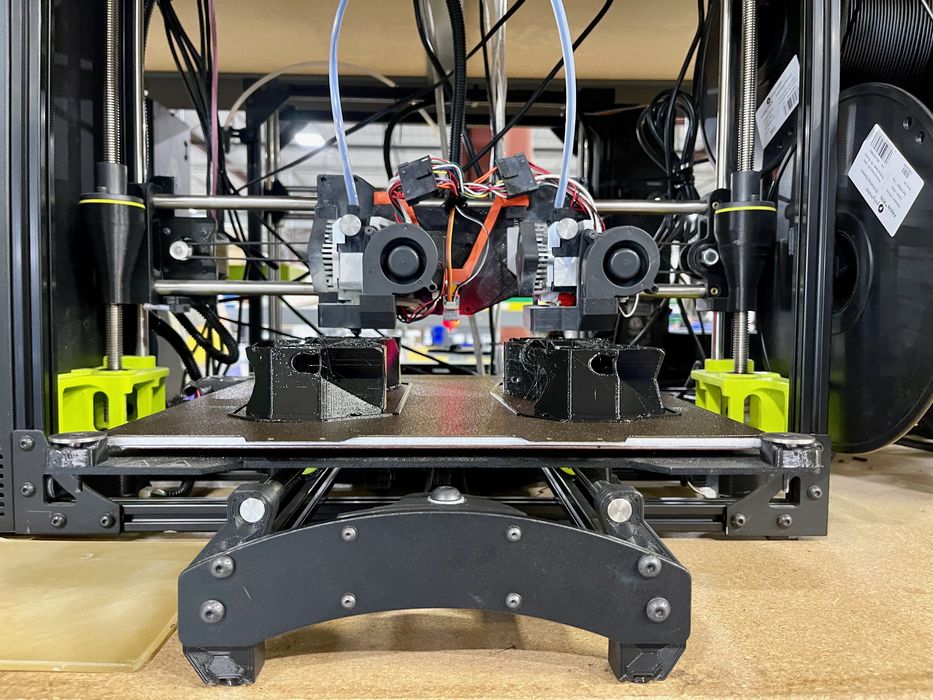

Here’s another example of the ingenious efficiency we encountered at FAME 3D: a dual head 3D printer. Now, dual extrusion isn’t exactly a novel development, but here they’ve modified an existing machine in their 3D print farm. This particular model doesn’t offer such a feature, so it was specifically designed for internal farm production.

The second printhead allows the unit to literally produce twice as many parts within the same print job. That’s double the efficiency, achieved with a relatively simple hardware modification. By implementing straightforward changes like this, a print farm of 100 machines really acts like 200 machines.

It all comes down to two things: an ability to design solutions combined with a strong desire to make things as efficient as possible.

This attitude might seem to be useful only on the production side, but we saw examples where it cascaded over into the product side.

Here we see one of FAME 3D’s most popular 3D printers, the Sidekick. It ships in flattened form, and must be unbolted and folded out after delivery. What’s extremely interesting about the Sidekick’s design is that some of the blocks used to hold the collapsed printer together during shipping are actually the same parts you use when assembling the machine!

This allows the company to save a bit on shipping because of lowered weight, and is a classic example of design ingenuity.

After seeing the “LulzBot method” in action at the company’s factory, I was quite impressed. It’s rare to see such a focus on efficiency, from the top to bottom of their operations.

There are many “smart” companies in the 3D print space, and I believe FAME 3D is one of them.

Via LulzBot