Trinckle continues to innovate with a new version of their tool-making software.

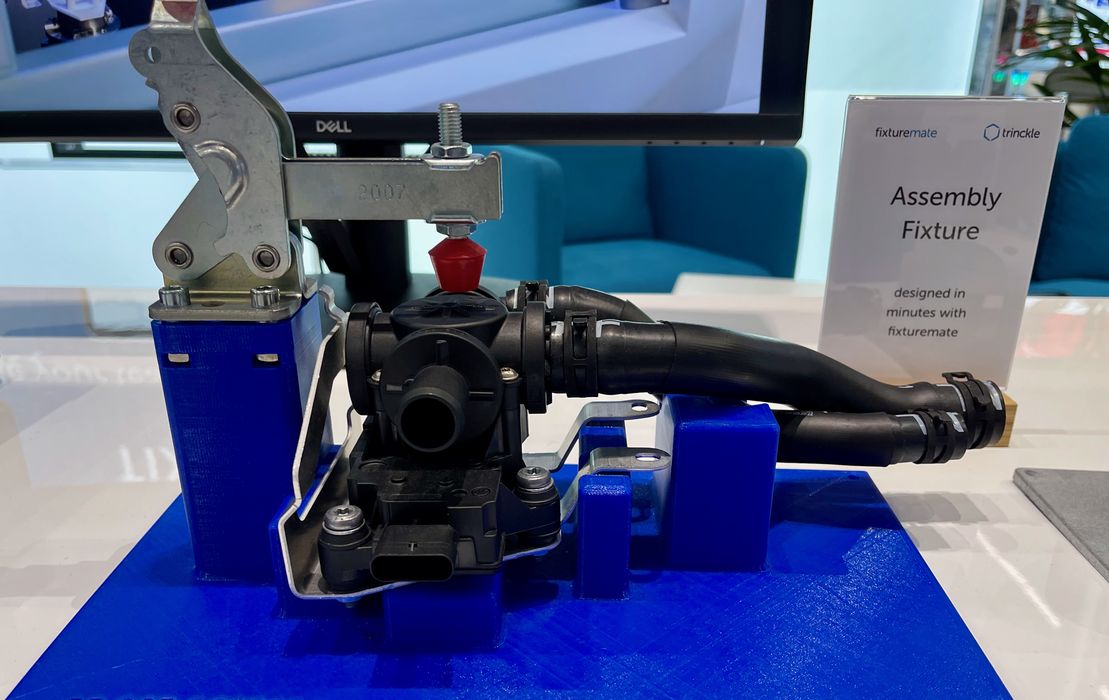

Trinckle is a software company with a focus on the ability to quickly generate 3D models for tooling. Tooling is growing in importance, as it allows for highly efficient manufacturing: tools are used to organize and align parts during assembly, for example.

The vision was always that factory workers could, with sudden inspiration, 3D print new types of tools to optimize their tasks. That is technically possible, but in practice hasn’t caught on so much.

Why? One of the biggest barriers is the inability for many people to create complex 3D models. While it’s easy to “hit print” on a 3D printer, where does the design come from? Traditionally the inspired worker would have to put in a request to the CAD department to have the 3D model created, which could take a long time to complete — if ever.

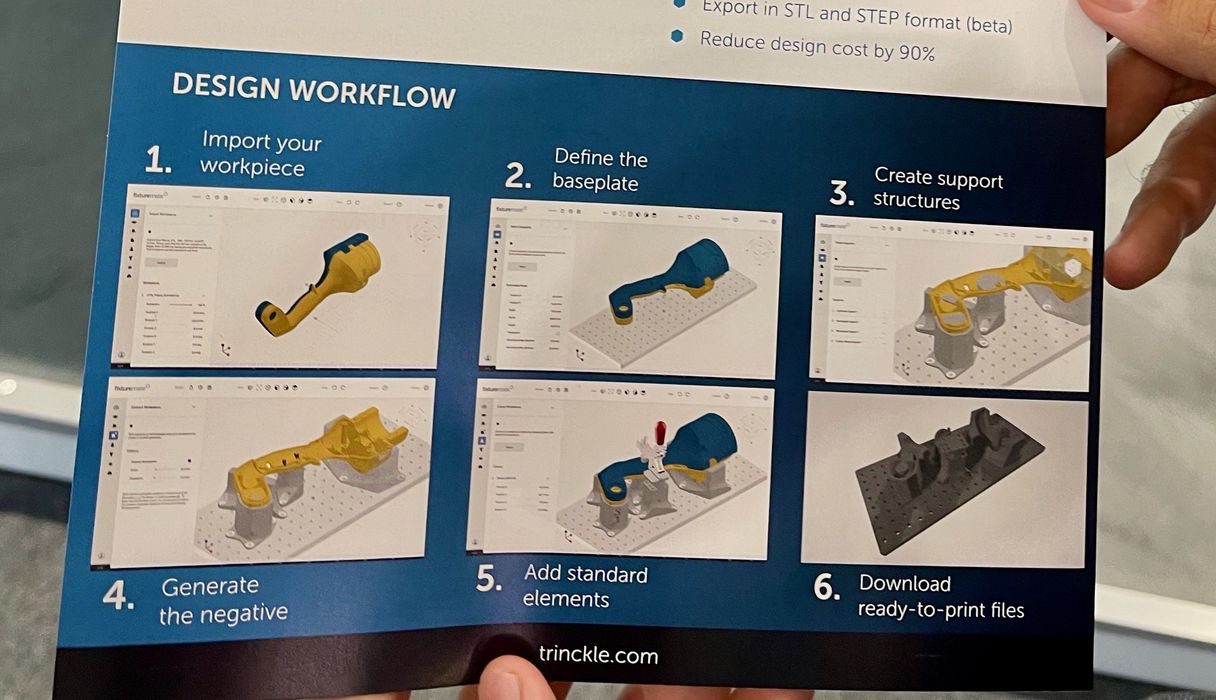

Trinckle’s concept is to simplify the design software so that anyone, even people without any CAD skills, are able to easily and quickly develop highly functional tooling models. These can then be quickly printed and put into action.

I recently spoke with Trinckle, and learned that they’ve just come out with version 2 of their software. This version includes an ability to export STEP files, which should make it easy to integrate Trinckle activity with the CAD department.

They’ve also streamlined the user interface, and I was told it was much easier to use. That should make it possible for users to get started in the tool even more quickly.

How easy is it to use this software? Just take a look at the steps involved in this guide to FixtureMate.

Trinckle has recently partnered with Sinterit, makers of a line of inexpensive SLS 3D printers. These devices print in nylon, and that material might be ideal for many tooling applications.

The partnership provides a free “beta” program to try out Trinckle with Sinterit equipment. This program’s length is a couple of weeks, and provides completely free access to Trinckle software. Sinterit explains how it works:

“We will start this program in January with a short training webinar for all selected participants. After that, you will receive free access to Trincle.com for 2,5 weeks. After the beta test, we will ask you to fill up a survey about your experience with the app (should take no more than 10 minutes). This will help us refine and improve the tool to better suit your needs.”

This looks to be a great way to see how advanced software can very quickly generate 3D models for jigs and fixtures for your manufacturing process. It would be ideal for managers to try out to see how the software would work in their environments.

Apparently there are only 30 spots for this program, so you may want to click this link to request access to the free program.

Tooling is one of the most important functions in our industry, but even so there are many manufacturing operations that don’t take advantage of 3D print technology. Trinckle’s software is one of the ways to open the door to manufacturing efficiency.

Via Trinckle