Stratasys announced two new 3D printers specialized for composite materials.

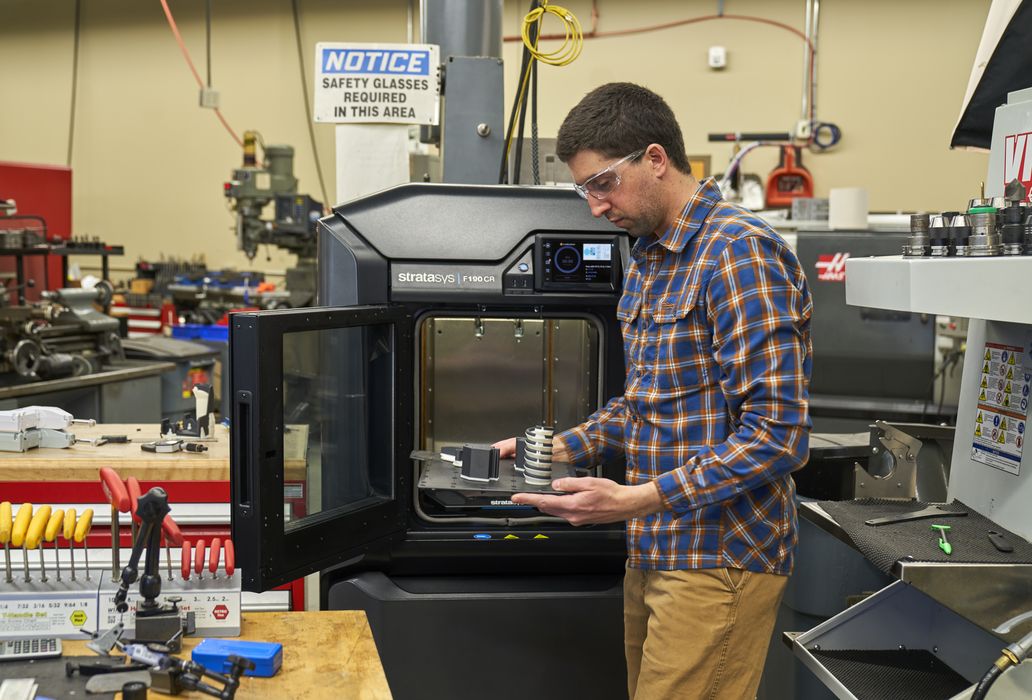

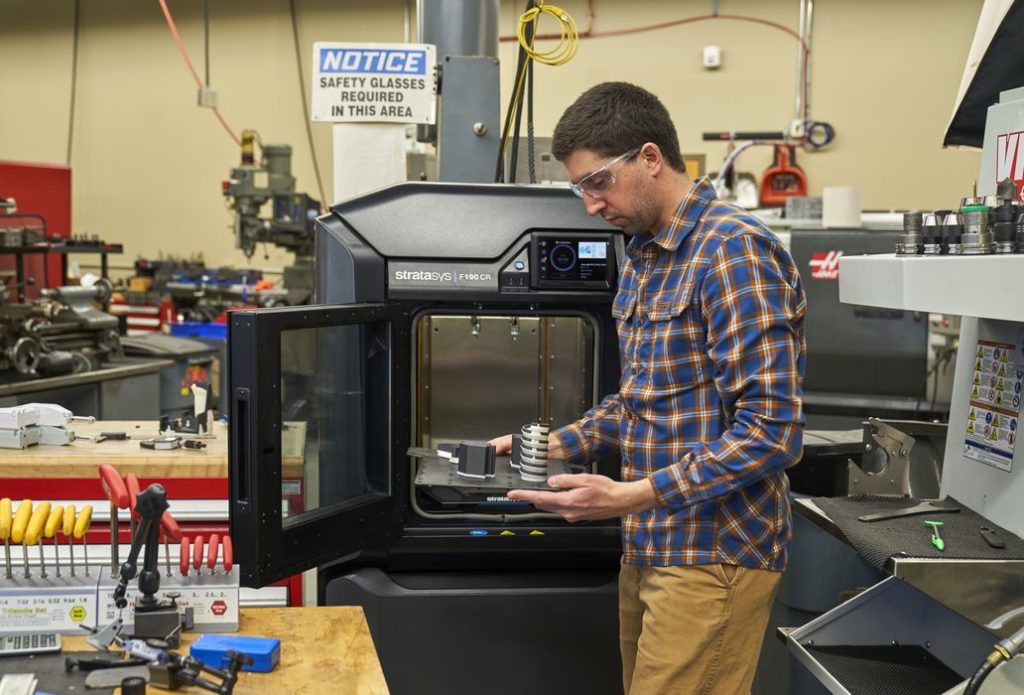

The new F190CR and F370CR join the company’s popular F123 series of easy-to-use industrial 3D printers, and share many characteristics with the existing F170, F270 and F370 models. However, the new models are optimized for use with composite materials.

By “composite”, they mean materials with additives to introduce different properties. At the moment that specifically means use of Stratasys’ ABS-CF10 (ABS reinforced with chopped carbon fiber) and brand new FDM Nylon-CF10. The new nylon material contains 10% chopped carbon fiber by weight, and is said to be 67% stronger and 190% stiffer than the nylon polymer used in the composite.

The challenge with composite materials is that they are difficult to 3D print on standard equipment. The carbon fiber content, introduced for strength, also creates a very abrasive material.

As the softened composite material flows through a nozzle, these carbon fiber segments drag along the surface of the metal nozzle. Being carbon fiber, they are harder than typical nozzle material: brass. Over time — and not a lot of time — carbon fiber filament can quickly erode a brass nozzle. Once eroded, the nozzle releases more material than expected, leading to compromised 3D prints.

To counteract this effect Stratasys has made changes to the F123 design to accommodate the material. The most important change is to replace the nozzle with one made from a much harder metal. Other manufacturers use hardened steel or even tungsten to accomplish this, but it’s not clear what material approach Stratasys used on the F190CR and F370CR. Nevertheless, these machines are fully capable of handling these strong, but abrasive materials.

The F190CR is the smaller of the two machines, and offers a generous 305 x 254 x 305 mm build chamber, while the larger F370CR has a build volume of 355 x 254 x 355 mm. While most other features are similar between the two machines, the main differences are that the F370CR includes four material spool bays, while the F190CR has only two. This means the F370CR can run unattended for longer periods. In addition, there are several additionally supported materials on the F370CR, including PC-ABS, Diran410MF07, and ABS-ESD7.

This is an interesting development for Stratasys and their F123 clients. The F123 series has become Stratasys’ go-to machine for many companies due to its ease of use and ability to naturally fit into a factory environment. However, the parts produced were not as strong as they could have been, at least until now.

The new machines allows existing F123 series operators to consider adding a composite 3D printer without changing their workflow significantly. This means they can very easily begin 3D printing much stronger parts.

That, in turn, opens up many more possibilities for part applications. The added part strength due to the composite material in some cases is sufficient to replace a metal part with a lighter weight thermoplastic part. For many industries, weight is a key advantage, and the use of carbon fiber reinforced plastic parts has been a rapidly growing phenomenon.

Stratasys will no doubt find the new composite machines to be quite popular.

Via Stratasys