Researchers at UC3M have developed a new 4D printer focused on the biomedical market.

“4D printers” are a bit different from normal 3D printers. The idea is that while a 3D object can be produced, it can change its shape after printing. For example, a print might “unfold” after printing to become assume the desired geometry.

Some 4D prints are dynamic in that they can change geometry when triggered by an external signal. This creates the possibility of printing machine components that can move.

The new device is a product of need. The group at UC3M have been exploring the 4D biomedical space, but encountered significant limitations in what the could produce.

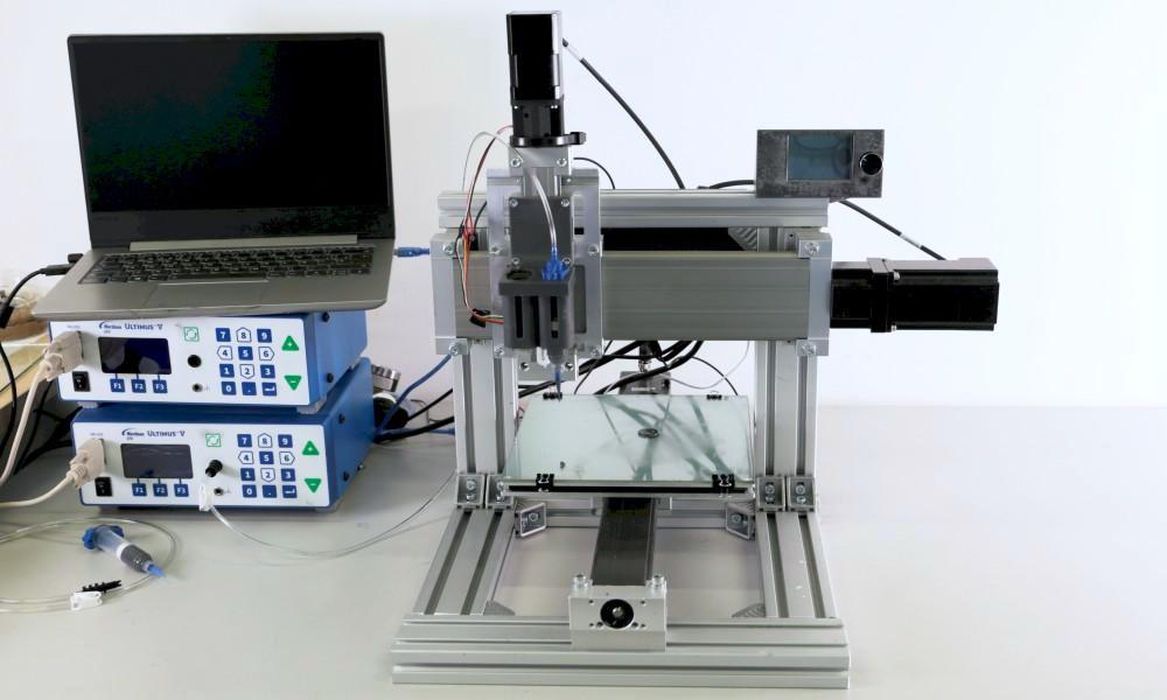

To solve this dilemma, they did what many entrepreneurs do: make a solution to that problem. They created a new 3D printer that is specifically designed to produce biomedical 4D objects. Their system includes not only the printer hardware, but also the associated software.

As a result, the 4D device can print objects that can subsequently be controlled through electricity.

Project head Daniel Garćia González explained:

“This technology allows us to not only control the way we print three-dimensional structures, but also to give them the ability to change their properties or geometry in response to the action of external magnetic fields, or the ability to modify their electric properties when they deform.”

This is more complex than you might imagine. UC3M explains:

“This type of printing is complex since the material to be extruded transitions from liquid to solid during the printing process. It is therefore necessary to understand the material dynamics to adapt the manufacturing process and obtain a material which is sufficiently liquid when it flows through the printer nozzle but, at the same time, solid enough to maintain a specific shape. To this end, they have developed an interdisciplinary methodology that combines theoretical and experimental techniques allowing them to build the printing device from scratch, both the physical part of the device (the hardware) and the computer programmes that allow it to be controlled (the software).”

The project also developed a “self healing” material that can be used with the 4D printer. This is especially welcome, as objects that bend might also develop flaws. With the new material, these flaws might never appear.

What applications might be in the future for this technology? González explained:

“We can think of sensors that, attached to our body, collect information about our movement from variations in electric conductivity. In addition, the material’s self-healing capability allows the design of sensors with binary signals. For example, if we have had a knee injury and need to limit rotation to a maximum value, we can incorporate a small band of this material over our joint. This way, when we exceed this maximum rotation, the material will break showing an abrupt change in its electric properties, thus providing a warning signal. However, when returning the knee to a relaxed state, the material’s healing capability will result in recovery of the electric signal. This way we can monitor our movements and warn of risky conditions after surgery or during rehabilitation periods.”

And that’s just one potential application. There will be many more.

Via UC3M