Researchers have developed a new and potentially very powerful new 3D printing process they call VIPS-3DP.

I’ve never seen anything quite like this, as the solidification process involves vapor. The name “VIPS-3DP” stands for Vapor Induced Phase Separation 3D Printing.

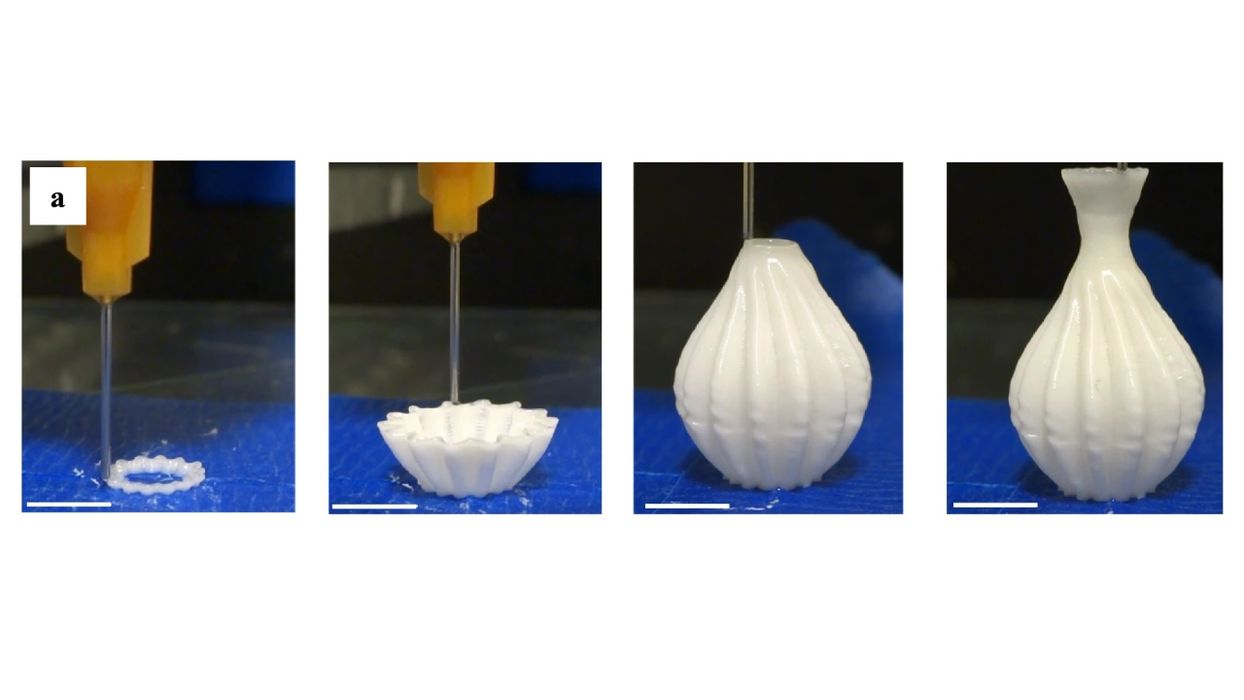

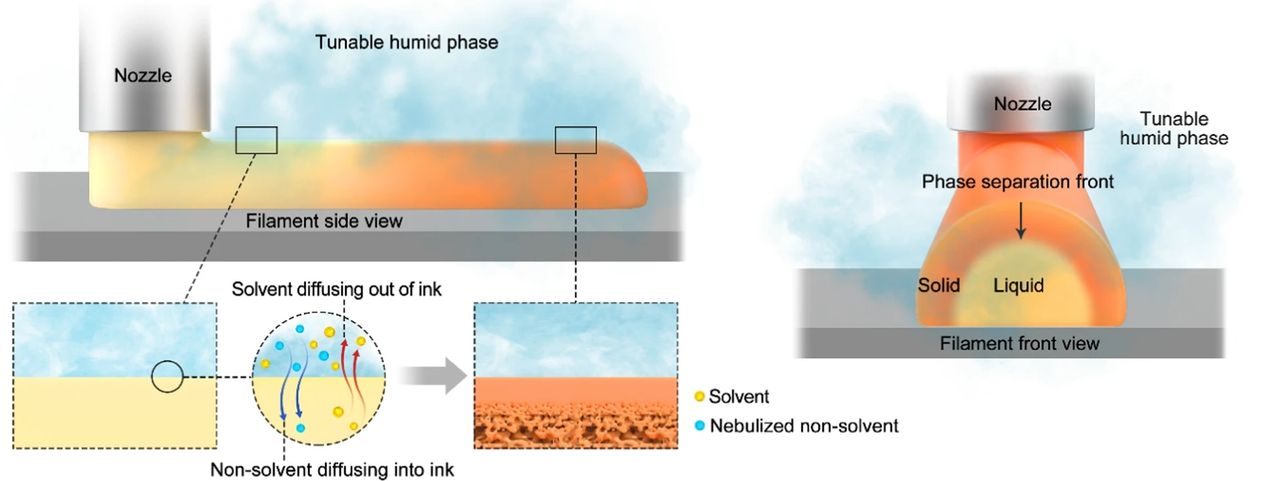

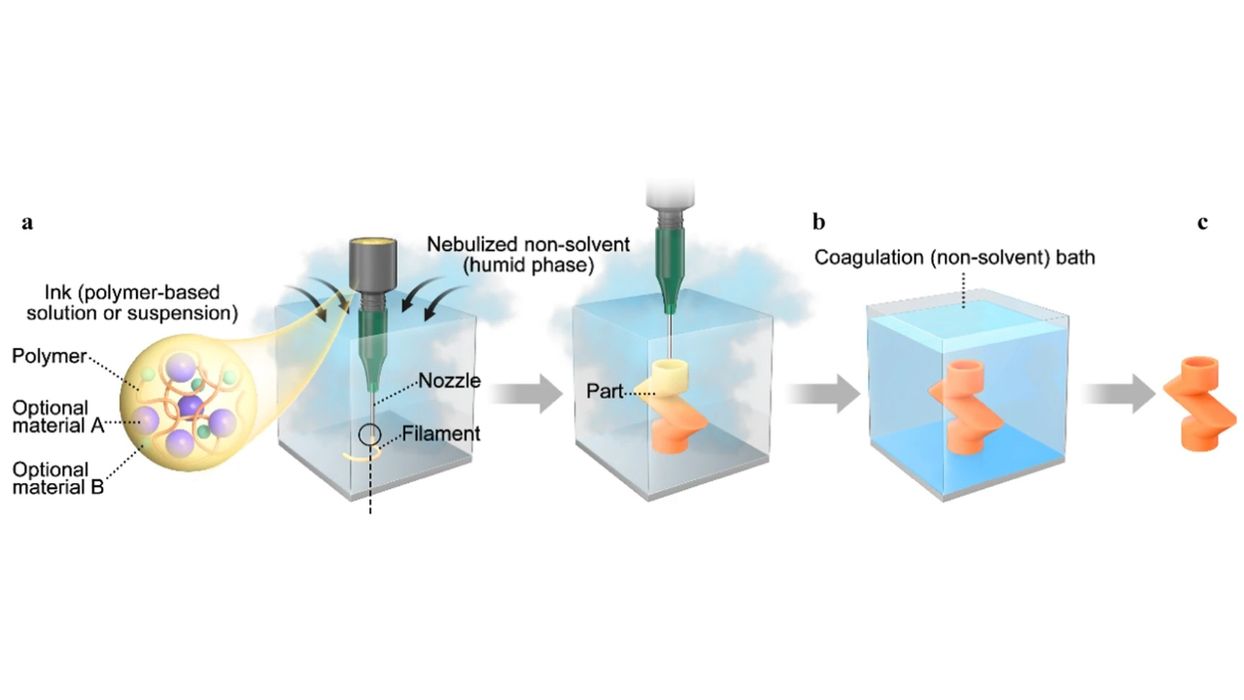

How does it work? It starts with a special liquid ink that contains particles of the desired 3D printing material. This liquid is extruded through a syringe-like nozzle into the build chamber.

As the substance exits the nozzle, it’s exposed to a flowing vapor within the build chamber. The vapor is made from a specific non-solvent.

Then the interesting part happens: the non-solvent vapor reacts with the liquid to extract a solvent, which results in a phase separation of the liquid. The phase separation causes solidification of the embedded particles.

The VIPS-3DP process could prove quite useful because it is compatible with not only polymers, but also metal and ceramic particles. It’s also possible to mix particles in the ink for hybrid materials. For example, the researchers were able to 3D print objects with composite materials using VIPS-3DP.

Ceramic and metal materials would have to undergo a post-print step for sintering the particles together, but that’s par for the course in many types of 3D printing. This step, however, suggests that materials mixing polymers, metals and ceramics might be challenging as they all have different sintering thermal profiles.

A unique capability of VIPS-3DP is that it is possible to control the porosity of the resulting object by tuning the print parameters. This allows the operator to have some fairly direct control over the strength and microstructure of the produced objects.

This research will almost certainly be commercialized in the future, as it seems too powerful to ignore. One question I have relates to the set of possible materials that can be used in VIPS-3DP. Is it compatible with all polymers, or are there some constraints?

Another question deals with the speed of VIPS-3DP. Videos of the process in action provided by the researchers show rather slow print speeds. If there are severe limits to the print speed, that might dampen commercializations hopes.

Nevertheless, VIPS-3DP is one of the most interesting new 3D print processes to appear so far in 2024.

Via Nature