We had a chat with the nice folks from WASP about their latest robotic 3D printing hardware.

The company has been around for many years and has focused on more niche areas of 3D printing. Our first encounter with them ten years ago saw them printing clays using in-situ materials. Since then they’ve developed a large array of different technologies to produce large prints in a variety of materials.

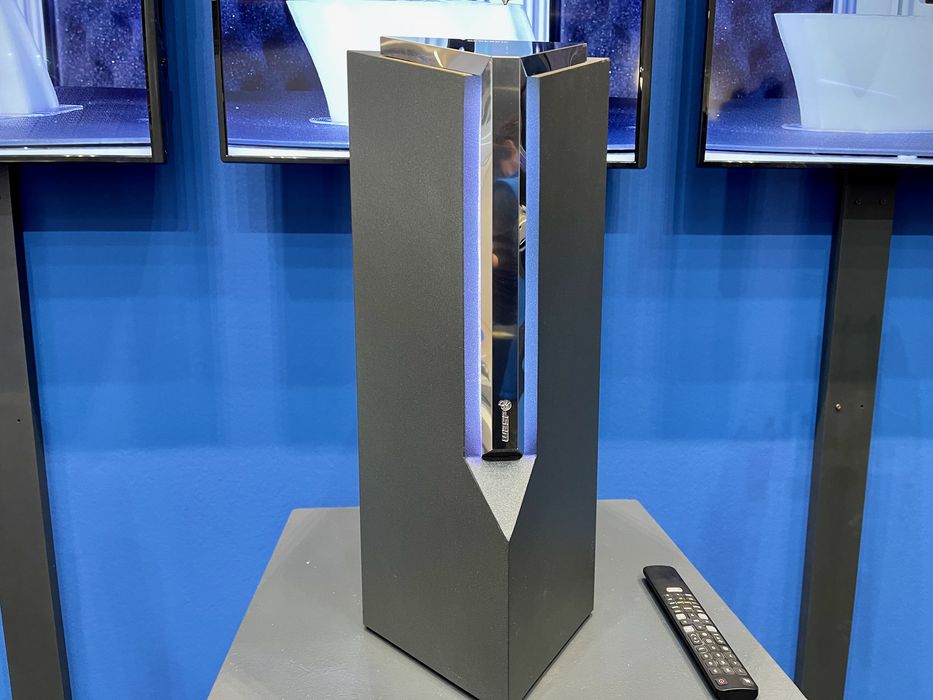

The new hardware is something called the “CEREBRO”, and let me explain how it fits in.

WASP produces three styles of 3D printers: clay, concrete and general purpose industrial polymer extrusion gear. Because of this wide array of capabilities, the company also offers the ability to use their toolheads on robotic systems. One of them is quite new, a pellet-based toolhead called “METAMORPHOSIS”, for example. METAMOROPHOSIS offers the ability to do color blending.

Many of their customers attach a toolhead to the their existing robotic systems. WASP does not produce robotic arms itself.

The problem comes in the integration step: how does the robotic system properly control the toolhead? Normally this is a challenging step that requires some effort to set up for customers because there are many different technical protocols that are possible.

WASP representatives told us that “every customer asks the same questions” in such situations.

That’s where CEREBRO comes in. It’s a specialized hardware controller that provides an integration layer for WASP toolheads attached to customer robotic systems. WASP decided to make a “universal solution” for this issue.

WASP told us, “it turns a robot into a 3D printer”.

This is an excellent step for WASP, as it will almost certainly overcome buyer hesitation: the effort for integration will be significantly reduced, and that means the cost and challenge to implementing a robotic 3D printing solution will be decreased.

I expect the company will garner more sales as a direct result of CEREBRO.

Via WASP