A company you may not have heard of is Holo.

The Silicon Valley company has been quietly working on additive manufacturing using a 3D printing process they call “PureForm”. The process is capable of producing large quantities of small, high resolution parts in a wide variety of metal materials.

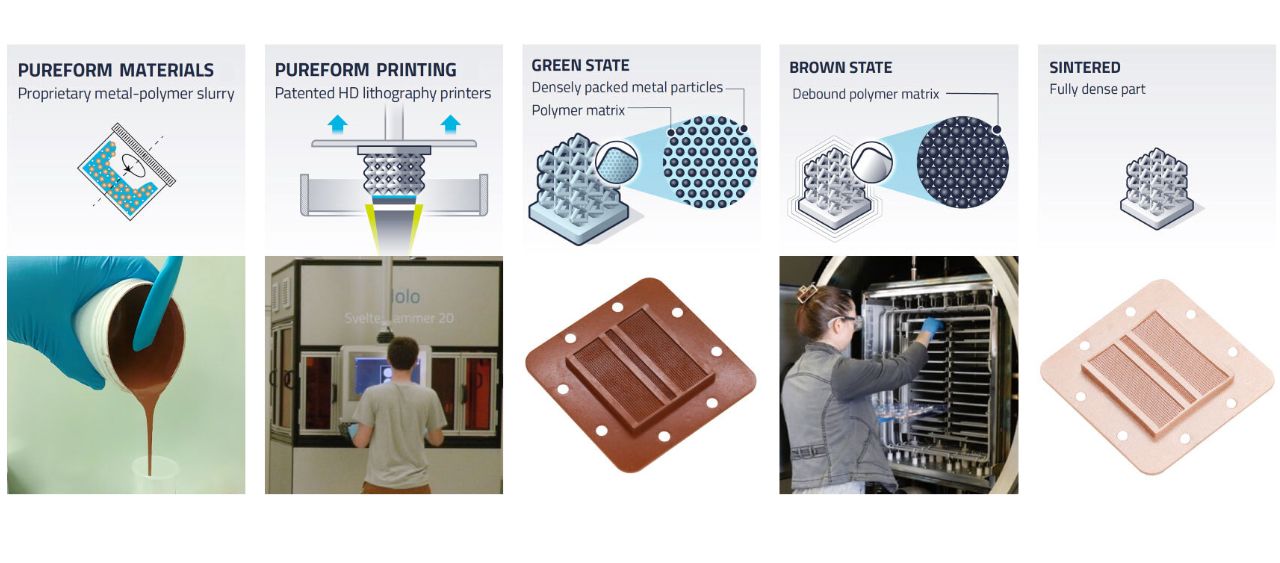

The PureForm process is unique, and patented. It involves using a “proprietary metal-polymer slurry”, which is 3D printed using what appears to be a photopolymer reaction.

The result of the printing process is a green part that is a mix of metal particles and polymer binder. Subsequent processes de-bind the polymer, and then sinter the metal particles together to form completely fully dense metal parts.

If that part of the process sounds familiar, it should: it’s the standard green / brown / part process used in a variety of 3D printing processes, and is well understood by industry.

In fact, that is the same process used by metal injection molding solutions. Holo wrote:

“The backend process is virtually identical to MIM.”

By some coincidence, PureForm actually uses MIM powder in their “proprietary metal-polymer slurry”. This means that it would theoretically be possible to print metal objects in a very wide range of MIM powders, although I’m not certain which MIM materials are currently used by Holo besides stainless steel, copper and even some ceramics.

However, PureForm differs from MIM in several key aspects. First, there’s no molds required, as the geometry of the part is produced by the 3D printing phase. This eliminates a huge expense and time delay, as parts can be printed immediately.

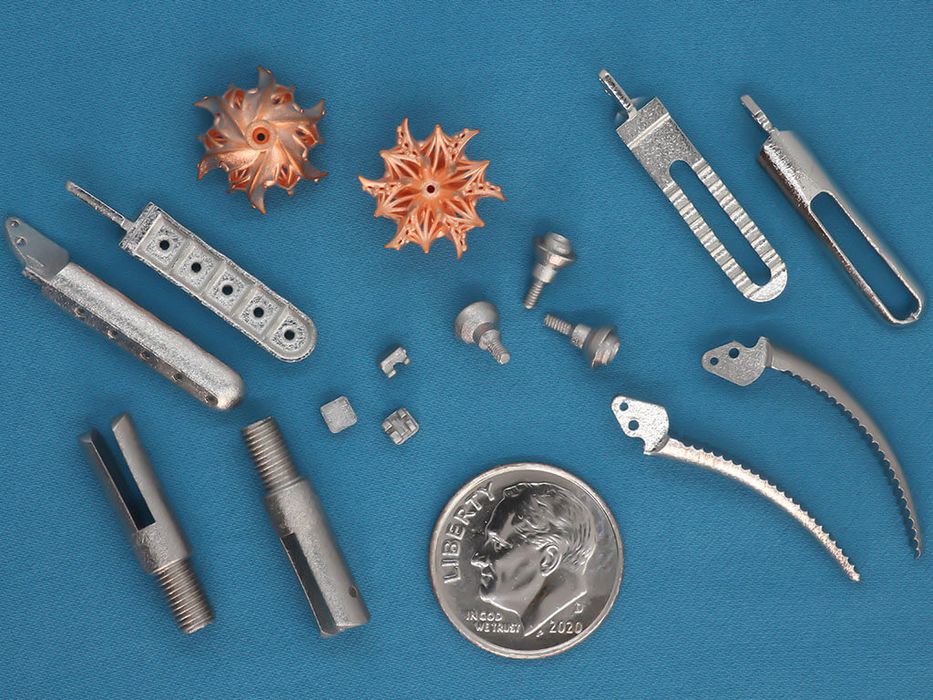

Holo said the PureForm process is able to produce parts with ”surface finish and feature resolution that meets or exceeds MIM”, and this is evident when looking at the sample metal prints above. PureForm can produce metal objects with features as small as 0.05mm.

Even better, their parts do not require post processing, as there are no support structures to remove and the surface finish doesn’t usually require any improvements.

Finally, PureForm is apparently a scalable technology. Since it is a cold process, there should be few concerns if larger versions of PureForm printers are attempted. Holo indicates that they can produce “10s of thousands” of parts per month using the process.

The company does suggest that actual MIM processes be used for higher volumes, which would suggest that PureForm users might consider designs that are feasible using injection molding approaches as a form of scalability insurance.

Holo is also one of the companies using an increasingly common business model for additive manufacturing: don’t sell printers, sell print services instead. You can’t buy a PureForm 3D printer, as far as I can tell.

This approach, used by others including Seurat and 3DEO, offers the advantage of not requiring a service network. It also allows the equipment to always run at fully optimized levels through dedicated experienced operators.

Because the equipment is behind the scenes, it can be improved and enhanced without interrupting customers, all the while providing a more efficient operation.

Holo was a spinout from Autodesk several years ago, and since then it has attracted multiple rounds of funding from a series of well-known VCs.

Most recently the company added a new member to their board of directors: David Behnaim. Behnaim just happens to be a co-founder of Markforged, one of the leading metal 3D printer manufacturers. Behnaim’s connections and long expertise in the space should add considerable power to Holo’s future.

Via Holo