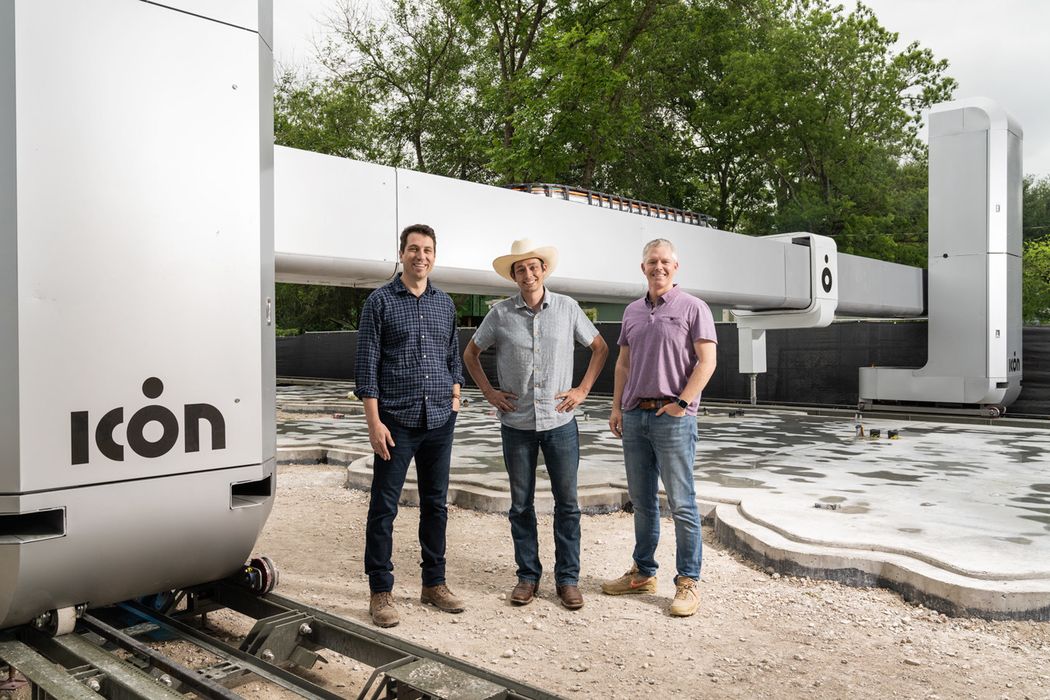

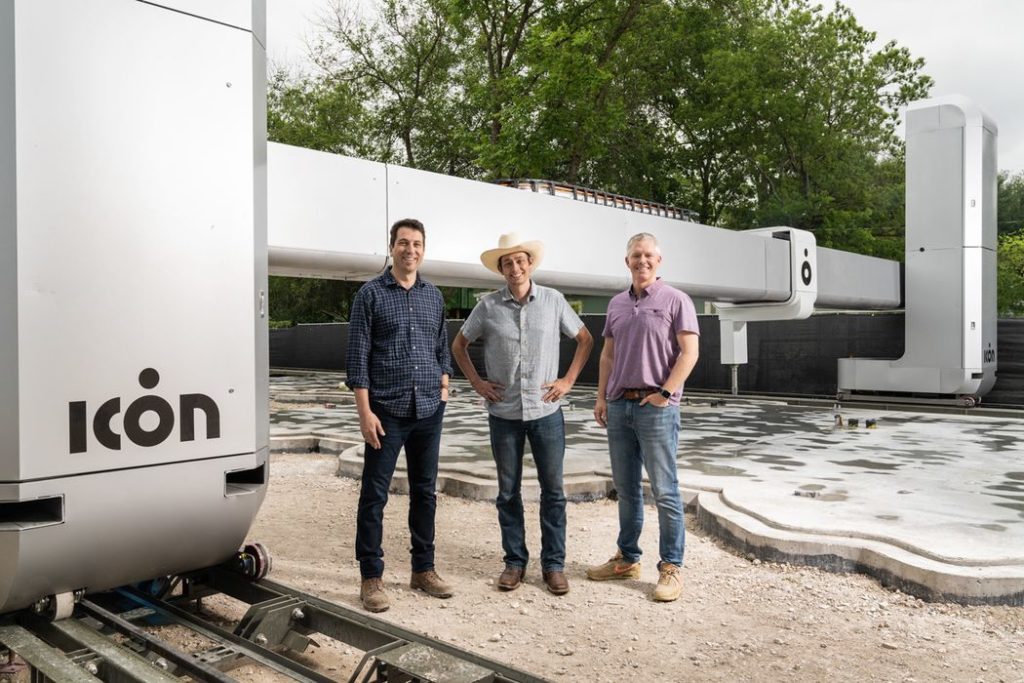

ICON announced yet another funding round, bringing their available cash to unprecedented levels.

The Austin-based construction 3D printing company announced a massive US$185M additional funding from investors. According to a report on TechCrunch, this is an extension of their prior Series B raise of US$207M. This means the Texas company has found itself awash with US$392M in only the past few months.

According to ICON, the company has raised a grand total of US$451M thus far, and industry speculation suggests this implies a total market value for the company of near US$2B. Were this company publicly traded, they would be at or near the top of our leaderboard of 3D printing companies.

There are two reasons for raising this impossibly large amount of money.

First, the injection of funds redefines the market value of the company. For example, if 10% of the company is sold for US$100M, then the value of the entire company must be US$1000M. In other words, the earlier shareholders receive a boost in the value of their shares because of the new investment.

Certainly a major reason for the raise is this increase in valuation.

The second reason for a raise is to gather funds for operational purposes.

But what, exactly, could ICON do with nearly half a billion dollars? That amount of money is so truly gigantic they could undertake almost any conceivable project.

If I were running ICON, and I most certainly am not, these are the projects I would consider launching with that fresh cash.

Printer Upgrade

ICON is currently in the midst of developing a new version of their Vulcan construction 3D printer. Their FAQ explained the new version will have:

“Tablet-based controls, advanced UI, 4x larger print area, 2.5x faster, automated material mixing, pumping, and delivery, safety features, remote monitoring, and on-board lighting for printing at night or in low-light conditions and more.”

Cash could speed up the development and production of the new Vulcan at a rate to match expected new projects.

Sales & Distribution Expansion

At this point very few construction companies use 3D printing technology, and that means there’s a large potential market. New cash could allow ICON to hire and fund a small army of widely distributed sales personnel to work directly with regional construction organizations to generate new projects.

Educational Program

ICON faces the same issue that plagues the makers of other types of 3D printers: the target customers don’t understand the technology, and don’t want to change how they do things.

Other manufacturers overcame this by setting up comprehensive educational programs, industry ambassadors, pre-made content, branding, business cases, case studies and other approaches to gradually gain the confidence of new clients. A big step by ICON to be establish this type of program that could more rapidly develop their market by “turning on” regional construction organizations.

Construction Division

ICON builds the 3D printers and partners with local construction companies to actually do the work. One interesting possibility is that ICON could decide to vertically integrate and establish their own construction company that would be ready to take on all aspects of 3D printed construction projects in-house.

The most obvious way to do this would be to acquire several key regional construction companies that specialize in projects most doable with ICON technology. The new cash could fund those acquisitions and get ICON a massive new line of business that could grow to global scale.

Eco-Friendly Material

It’s gradually becoming understood that concrete is actually a material very unfriendly to the environment. The manufacturing process for producing cement generates at least eight percent of global CO2 emissions.

As the climate emergency intensifies, this source of emission will come under increasing scrutiny. ICON uses a proprietary mix they call “Lavacrete”, which is likely based on cement technology. CO2 generation will conflict with ICON’s future growth plans at some point, and it could be in the company’s long-term interest to resolve it.

ICON could put some resources toward the investigation of alternative materials for their VULCAN system that would be more environmentally friendly.

Will ICON pursue all of these paths? I have no idea, but it’s likely at least some of them may happen in coming months and years.

Via ICON