Today’s ultra-low cost 3D printers are a far cry from their predecessors.

Not a few years ago, the notion of a “cheap” 3D printer made me shiver. Several 3D printer manufacturers attempted to make devices at in the US$100-200 range, and “succeeded”.

By “succeeded”, I mean they technically achieved their goal, but the machines were not particularly useful. The devices used the most inexpensive parts and were not equipped with any features that make 3D printing practical.

It was a race to the bottom, and when the bottom was reached there wasn’t much left. As a result, interest in these less-than-capable-but-inexpensive machines dropped. Most users focused on more expensive machines that offered ease-of-use features and produced good, reliable output.

Recently I ran across an ultra-low cost 3D printer and decided to take a critical look at it, as compared to the bare-bones cheap machines of the past. Have things improved as they have for higher-priced machines?

The machine in question is the Voxelab Acquila. If you’ve not heard of Voxelab, it seems to be a new brand from Flashforge, a long-time producer of desktop 3D printers.

The Acquila is an open-format desktop 3D printer that is currently listed for only US$168. That’s a rock-bottom price if I ever saw one. It’s so low that customers might consider buying it sight unseen, as that amount of cash is not a lot to lose.

The big question I had was this: would today’s inexpensive machine be stripped of features as were the inexpensive machines of the past? Let’s take a closer look at the Acquila.

At first glance, the Axquila appears similar in design to many more expensive units. It uses the standard H-style design with pulleys rolling on aluminum extrusions, a proven solid configuration.

The Acquila includes a color screen, a feature you would not see on older inexpensive machines. Usually you’d see a cheap LCD panel with a few lines of alphanumeric characters, or even nothing at all. The Acquila’s screen is a vast improvement. However, it’s not a touchscreen; you must rotate a convenient knob to access menu options.

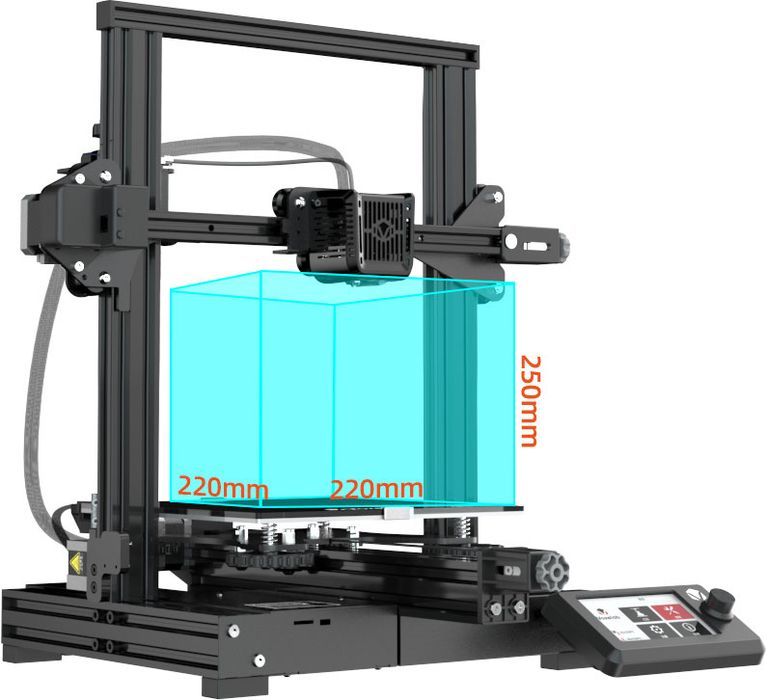

The build volume is significant on this device at 220 x 220 x 250 mm. Typically older inexpensive machines would dumb down the build volume to as low as 100 x 100 x 100 mm. This is not the case on the Acquila, which sports a build volume as large as many more expensive devices.

While the Acquila is a kit that you must assemble, the process of “assembly” is really just bolting a few parts together. This is not like the original 3D printer kits that included dozens of nuts and bolts, wires, and a lot of work required. No need for soldering here.

The print surface is heated sufficiently for even ABS 3D printing, and it’s made from glass. This provides a very flat surface, but it will require some adhesive solutions for most materials, and may not be as easy to remove 3D prints as more expensive machines equipped with flexible spring steel plates.

The Acquila includes a power off feature, where the machine remembers its position and can resume 3D printing when power is restored. For a long time this was considered a premium feature available only on the more expensive devices, but here we see it on the lowest-cost machine. That’s progress!

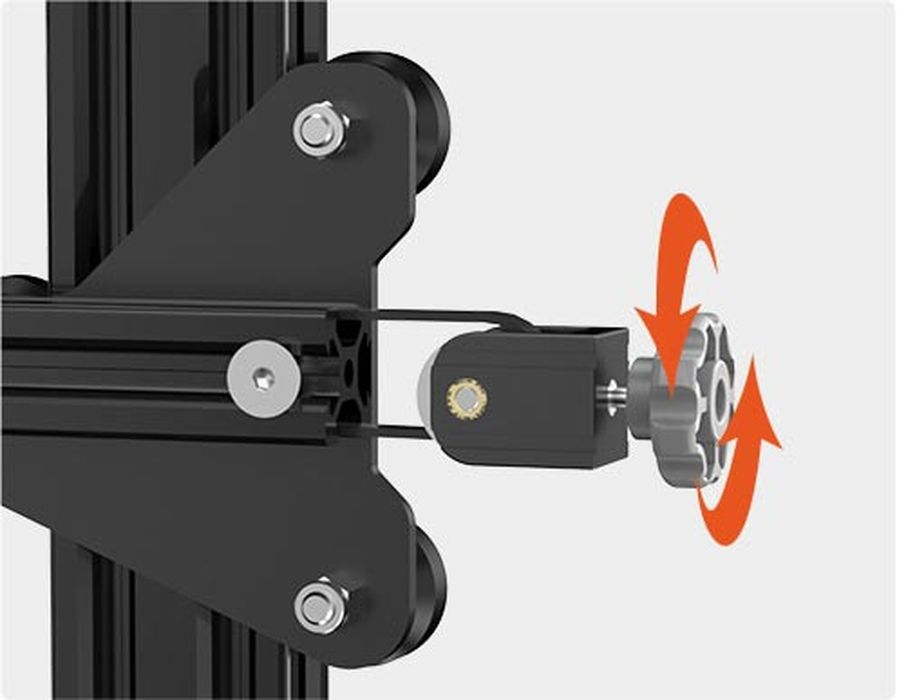

Another very interesting feature is the adjustment knobs for belt tightness, which are easily accessed. This is massively simpler than older systems where you had to more-or-less disassemble the machine to tighten belts.

The extruder on the Acquila is designed for easy filament loading. An inserted filament is automatically grabbed by the extruder gears, making it very straightforward to operate.

The stepper drivers on the Acquila are advanced and operate completely silently. Again, this is a premium feature that has somehow found its way into a low-cost device.

That is the list of key features on the Acquila, but what is missing?

The biggest missing feature would have to be automated calibration. Many devices now include a way to automatically sense the build plate’s orientation and adjust accordingly. This is not present on the Aquila. However, the glass build plate is by definition perfectly flat and this may simplify manual leveling procedures considerably. The glass plate also helps heat up the bed to operating temperature in only five minutes, so that’s a bonus.

Another omission is the now de-facto standard spring steel plate, but the glass plate will be fully functional with adhesive solutions.

Other than that, it seems that the Acquila is a very well-equipped device for this very low price.

Via Voxelab