Many things are recycled in 3D printing, but what about IPA?

IPA, or isopropyl alcohol, is frequently used in resin 3D printing to clean wet resin off of freshly completed prints. This works very well, as the resin dissolves into the IPA, leaving a clean print.

Typically resin 3D printer operators have an IPA setup to perform this cleaning. It can be a “Wash” device that holds the IPA and spins it around for quick cleaning, or others simply have a tub of IPA and tools to dip prints.

Sometimes there are “clean” and “dirty” tubs. The “dirty” tub is the one the print first goes into, which removes the majority of the resin. The second, “clean” tub is used to remove the remaining resin with a less polluted IPA solution.

That’s because the dirty tub becomes very saturated with resin, and parts will be exposed to that dissolved resin, along with its muddy color. At some point the IPA in the dirty tub is so saturated it has to be replaced. Even the clean tub will eventually become dirty.

What happens to this dirty IPA?

There are methods to clean resin-filled IPA. One way is to simply put the dirty solution in a clear container and leave it in the sun. The UV rays from our star will penetrate the transparent container and activate the resin, much like a 3D printer would do. However, unlike in a printer, the solidified bits are not connected to each other, and they simply fall to the bottom of the container.

You’ll end up with a sludge, not a solid piece, unless you pour off the IPA and leave the sludge to solidify on its own. Once solidified, you can toss it out, and the IPA should be relatively clean. The process can be repeated to further purify the IPA. However, there is loss of IPA due to evaporation, so you must be sure to close off the container from the air.

This is a very time consuming process; it can take days for the sludge to be processed, and so it’s not something you want to do often. Yet clean IPA is something we do need for resin 3D printing.

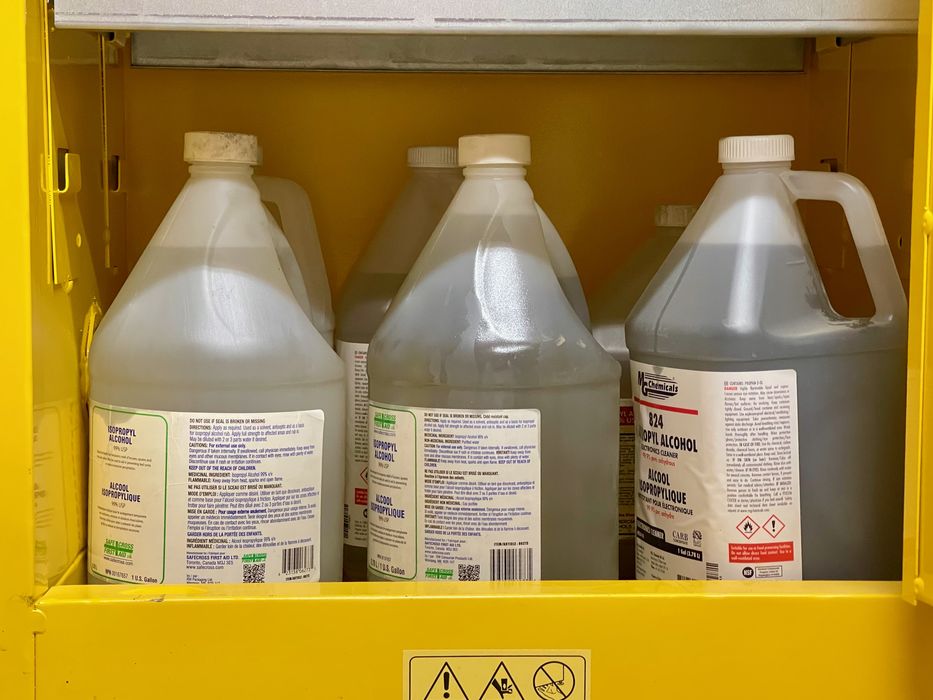

Some operations have trouble with dirty resin. At top you can see an image from one facility that is literally storing containers of dirty IPA in the hope of some future method of dealing with it. You can’t just dump it down the drain, as it’s toxic until fully exposed to UV light. Companies sometimes don’t have the time or space to lay out many tubs of dirty IPA in the sun.

With the increased interest in sustainable 3D printing, we’ve seen advances in materials, energy use and other innovations. I’m wondering if it would be practical to create a device that could safely and efficiently recycle IPA.

I could imagine the device would have a transparent reservoir that would be illuminated with strong UV light to cure the dissolved resin. This would fall to the bottom of the tank. A second reservoir could siphon off clean IPA from the top of the first reservoir. In the end you would simply dump out the solid bits from the first reservoir and use the “new” IPA from the second. It should be as straightforward to make as any of the existing “wash and cure” stations.

But we haven’t seen any such product appear, or even be hinted at by 3D printer manufacturers.

One possibility for the absence of such a product is the financials. If an IPA recycler was produced, it would probably cost a couple of hundred dollars at least, if not more. Current pricing on wash & cure stations is several hundred dollars, and this hypothetical device would be at least as complex.

3D printer operators would then be faced with a decision: spend US$500 on an IPA recycler, or just buy a lot of IPA. Let’s do some arithmetic to see if this makes sense.

You can purchase bulk 99% IPA for about US$1 per liter, so if a recycler costs $500, then you’d have to go through at least 500L of IPA before breaking even. That’s a lot of IPA, considering that each batch would be used for many prints.

It seems to me that a recycler would make sense only for an operation that’s using a huge amount of IPA on a regular basis. Those operations do exist, but it may be there are too few of them to justify development of an inexpensive and convenient IPA recycler for 3D printing.

It looks like the concept of a desktop IPA recycler is probably doomed.