SPONSORED CONTENT

Zaxe’s three new 3D printers address different markets.

You may not have heard of Istanbul-based Zaxe, yet they’ve been around since 2015 building 3D printers, until now mainly for the Turkish market.

Their first device, the X1, was released in 2016. It was enhanced as the X1+ in 2017, which offered a much larger build volume. While their X2 model proved extremely popular in Turkish educational institutions, the company also developed the Z series of industrial devices in 2019. Today they have 45 staff.

Today, the company is launching not one, but three new devices, the xlite+, Z2 and Z3.

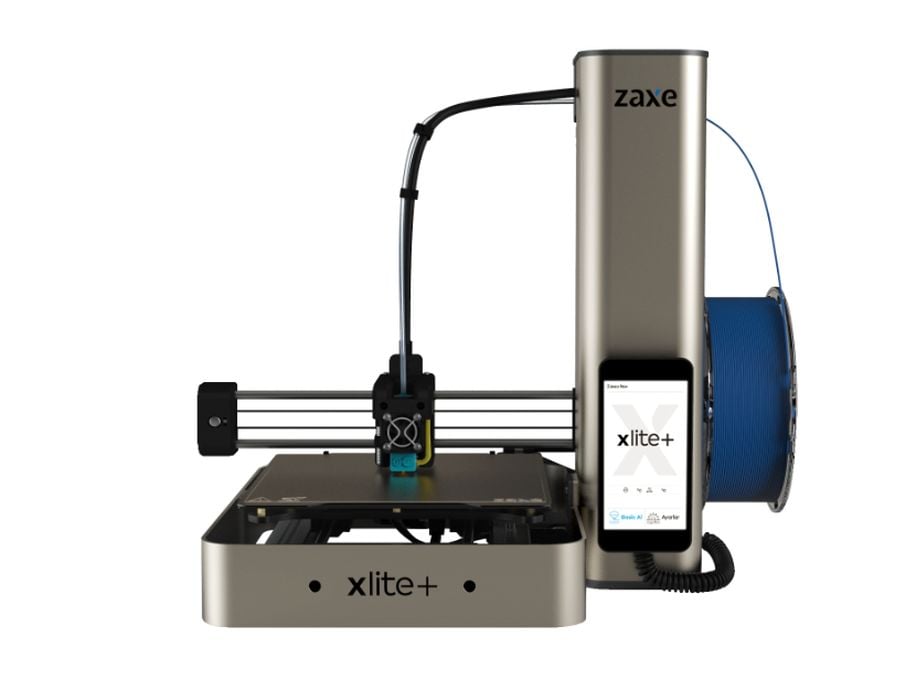

Zaxe xlite+

The xlite+ is an open-format 3D printer offering a generous build volume of 220 x 230 x 200 mm. While the open format might suggest the device is as basic as many other inexpensive devices, there are several less visible, but important features on the xlite+.

One feature is that the device includes fully automated calibration. This involves performing a mesh bed leveling procedure and adjusting the Z-gap on the nozzle. Some less expensive devices still require manual calibration, but the xlite+ does not.

The xlite+ uses an E3D-Online extruder that’s been custom-fitted with a titanium nozzle. The presence of this extremely hard nozzle allows the use of abrasive materials, such as carbon fiber-filled nylon.

Zaxe Z2

The Zaxe Z2 succeeds the X2, and offers higher speed 3D printing. While the previous model had a maximum print speed of 80mm/second, the new Z3 can 3D print at up to 300mm/second in optimal conditions. You won’t always run at that speed due to the geometry of parts, but the Z3 will certainly be able to print parts much more quickly than many other desktop 3D printers.

The Z2 includes several features of the xlite+. Including the color touchscreen, removable build plate, automated calibration and customized titanium nozzle. The machine is also capable of networking with the Zaxe cloud service.

Aside from the high-speed printing capability, there are two other major differences between the xlite+ and the Z2.

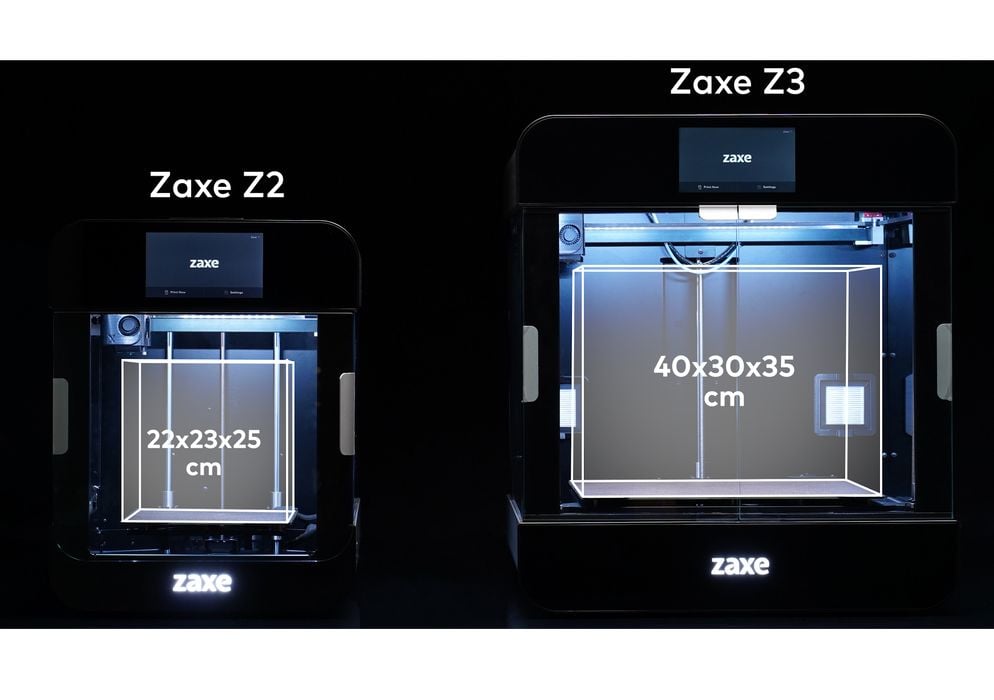

The Z2 has a taller build volume of 220 x 230 x 250 mm. This is quite complementary to the high-speed capability: larger prints can take place within the same time period within the build chamber.

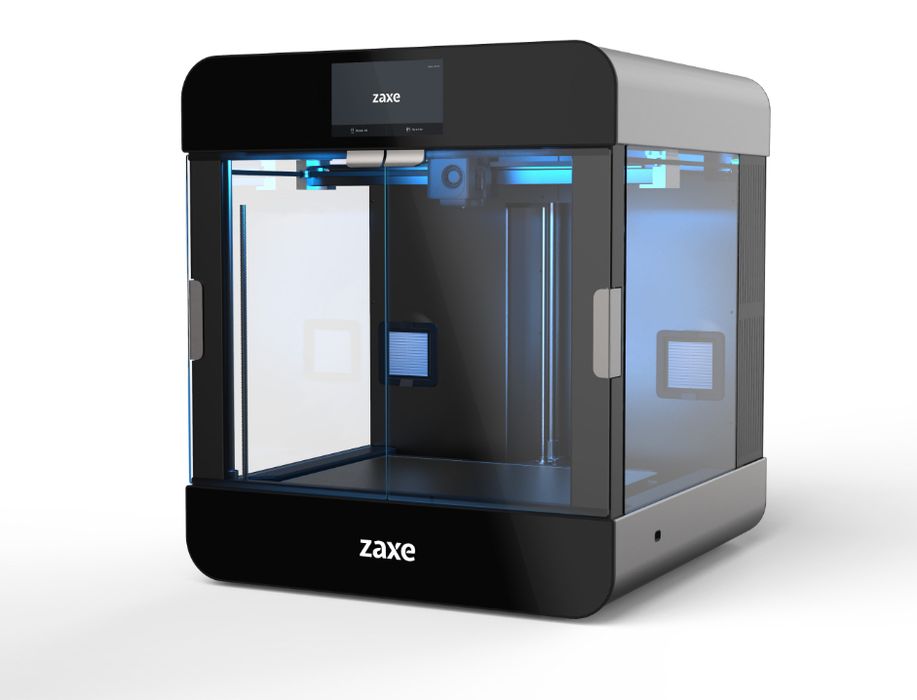

Finally, the Z2 is an enclosed machine. While the glass doors offer some safety, there is a major practical benefit: increased print quality. The enclosure allows the machine to accumulate some heat produced by the print surface. This raises the temperature of the build chamber, and lowers the thermal difference between freshly printed objects and the surrounding air. In other words, the temperature gradient is lower, and thus warping will be significantly reduced.

Zaxe Z3

The Zaxe Z3 is the flagship 3D printer for this release. This device has a massive build volume of 400 x 300 x 350 mm, over 4X the volume of the xlite+, to put it in perspective.

Like most current 3D printers, the Z3, as well as the Z2 and xlite+, include a color touchscreen and networking capability. These machines can all connect with the Zaxe cloud system, which provides a number of additional functions, including file management, remote monitoring and control.

I’m happy to see Zaxe includes a removable, flexible print surface with all machines, including the top-of-the-line Z3. This plate, coated with an adhesive solution, allows not only good adhesion during printing, but also quick print release after completion by simply twisting the plate — the print easily pops off.

The Z3 includes all the features present on the xlite+ and Z2, most notably including the Z2’s high-speed 3D printing capability.

This means it is possible to 3D print very large objects in rapid time in that huge build chamber.

Zaxe said the Z3 is “compatible with all materials”, and that is enabled by the hardened nozzle and enclosed build chamber, which captures stray heat. Engineering materials tend to require somewhat higher temperatures than most desktop 3D printers are designed to handle.

When you combine the ability to print at high speed with many engineering materials, you have the recipe for an industrial device that can produce end-use parts in low volumes.

Zaxe Pricing and Availability

Pricing for the three machines is as follows:

- xlite+ : €990 (US$1166)

- Z2 : €1990 (US$2340)

- Z3 : €2790 (US$3280)

The machines are available for purchase now at Zaxe’s online store.

Via Zaxe