A new sapphire-equipped 3D printer nozzle may eliminate abrasion issues, enabling the ability to 3D print very strong materials.

Dura-Gem is a newly developed 3D printer hot end nozzle that includes a unique sapphire tip. Strapping gems onto your hot end is not simply to make the hardware more attractive; there’s a very practical purpose behind this move.

Typical 3D printer hot end nozzles are made from brass, which turns out to be a rather soft metal. While it is perfectly adequate to 3D print many plastics, such as PLA and ABS, it has challenges when extruding any materials containing harder substances, such as carbon fiber, copper, iron or almost any metal infusion.

The challenge is that the harder materials, even in powder form, gradually abrade the wimpy brass nozzle. It can widen the nozzle slightly, change its shape and even shorten it, so that your Z-gap settings are invalidated. All of these can result in a variety of 3D printing issues.

Even worse, there’s a growing interest in printing with composite filaments, the materials that can cause these problems.

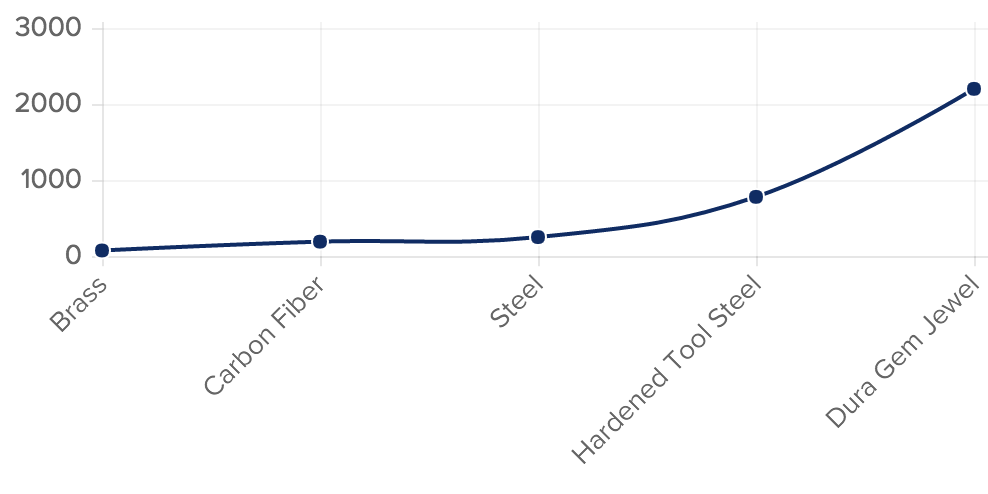

Enter Dura-Gem, which includes a small sapphire tip. This is apparently sufficient to avoid all these problems. Why? It’s because sapphire is simply a harder substance than not only brass, but other commonly used nozzle materials, too, as you can see in this chart.

According to Dura-Gem’s Jonny Hurst:

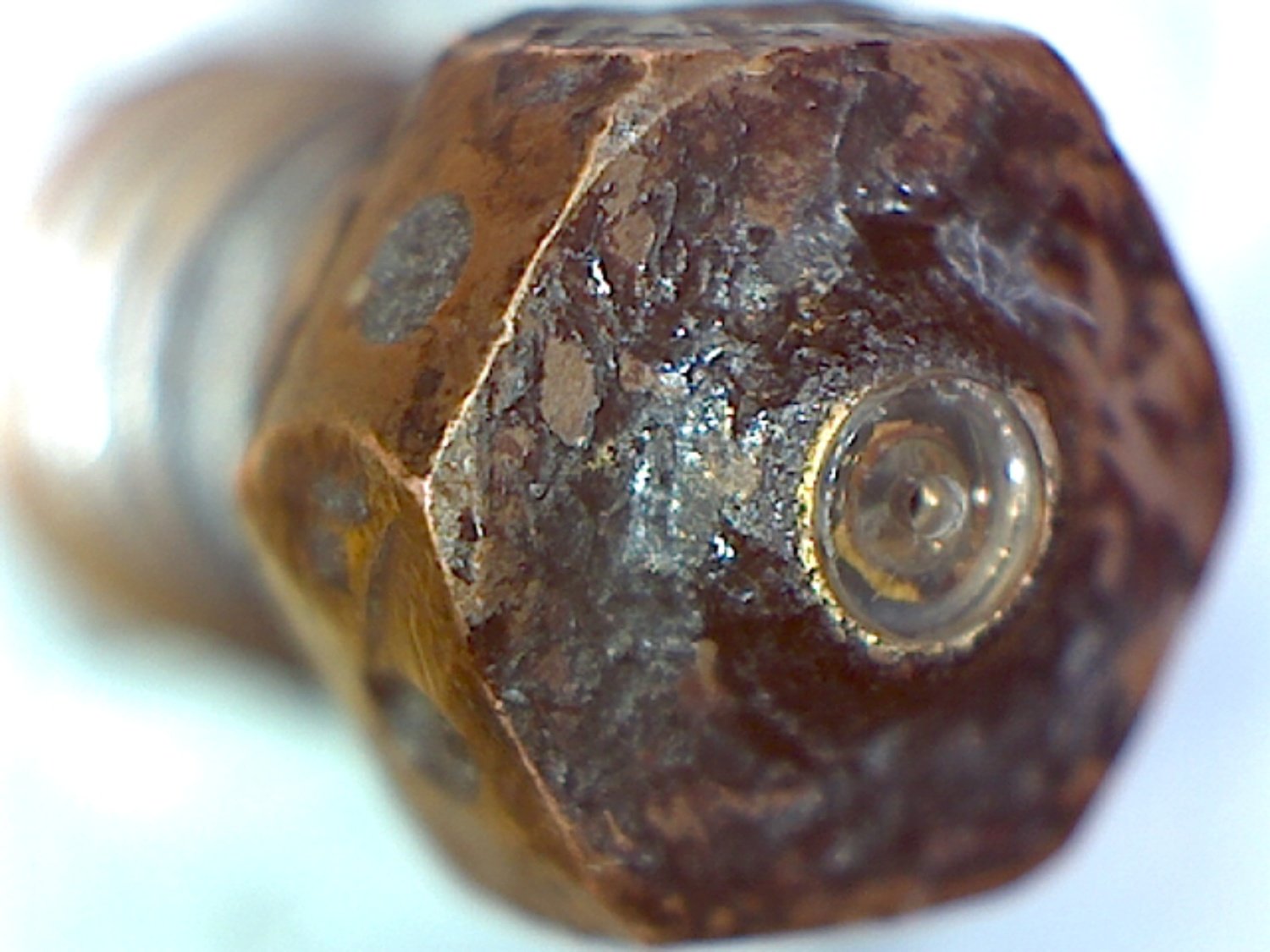

Over the past 4 years I have been dealing with these issues and became frustrated with 3D printing and the constant calibration. That is why a year ago I started to develop a special nozzle “Dura-Gem” made with the most precious materials to solve these issues. I have been printing with a proto-type nozzle with a sapphire jewel attached to the tip. Sapphire is one the hardest material known to man and are used in many applications requiring durability and wear resistance.. I can now make large carbon fiber reinforced parts and metal filled statues without the added cost of failed prints and frustration constant calibration. I have run approximately 5kg of various abrasive materials through the Dura-Gem nozzle without any measurable wear.

The company has performed microscopic measurements on their prototype sapphire nozzle and also found that plastic does not stick on the sapphire, either, which could reduce the occasional black goop that falls off brass nozzles into your otherwise pristine, white print.

Is this amazing innovation available? Not quite yet, apparently. According to Dura-Gem’s site, it is “Coming Soon”. But you can sign up to be notified when it is available.

Via Dura-Gem