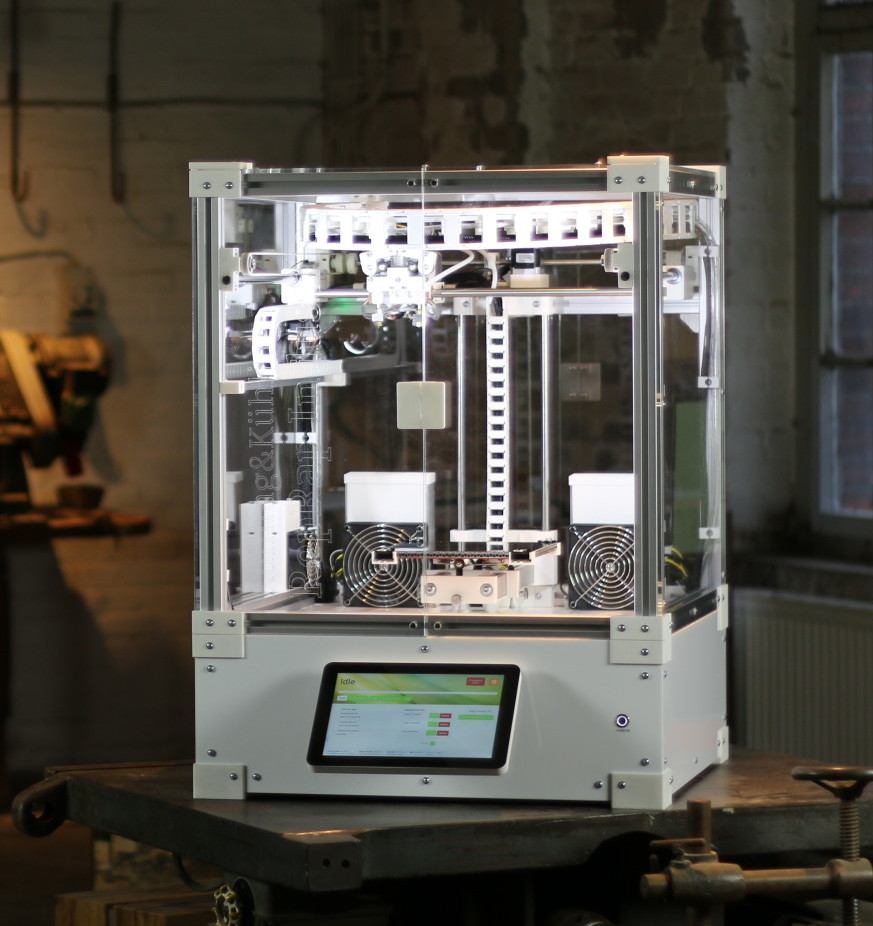

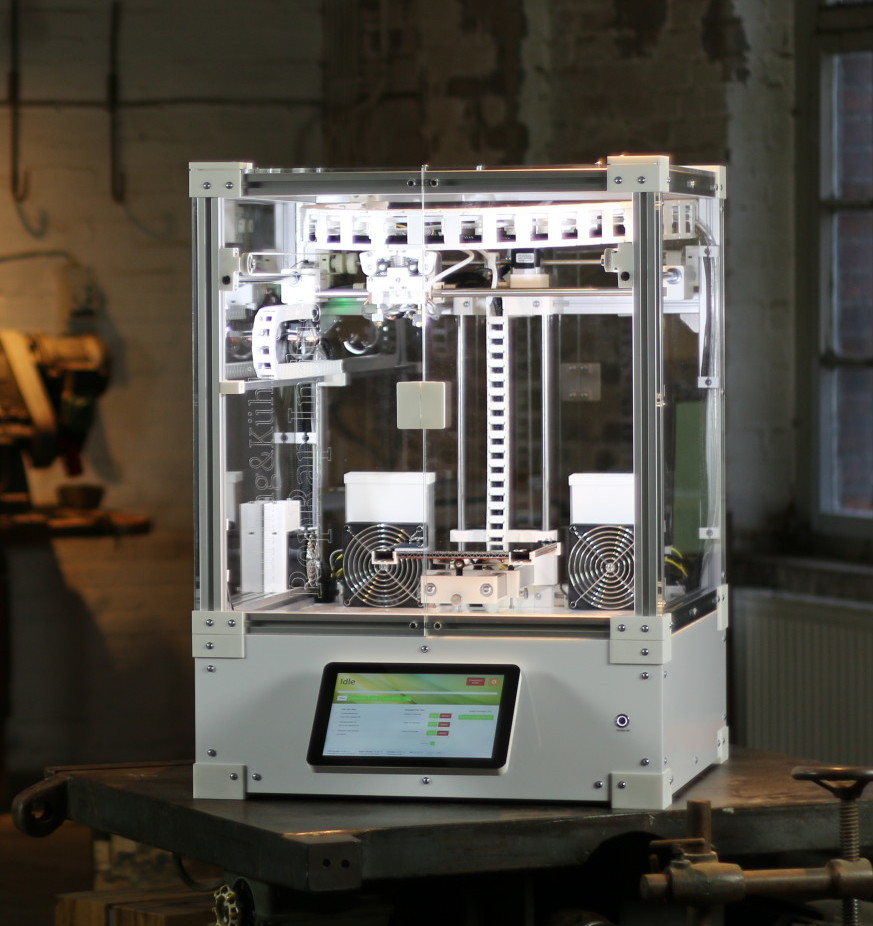

Germany-based Kühling&Kühling’s new HT500 3D printer is not only reliable, but also offers one of the highest print temperatures I’ve seen.

Kühling&Kühling (named after the two brothers who designed the devices) have been making high-quality 3D printers for several years. I first saw them at Euromold a few years ago where they were demonstrating a powerful and quite large desktop 3D printer that attempted to fit into the “low cost industrial” niche. The machine was impressive at the time, and so it is today, with the introduction of their new HT500 machine.

Let’s look at the specs for the HT500:

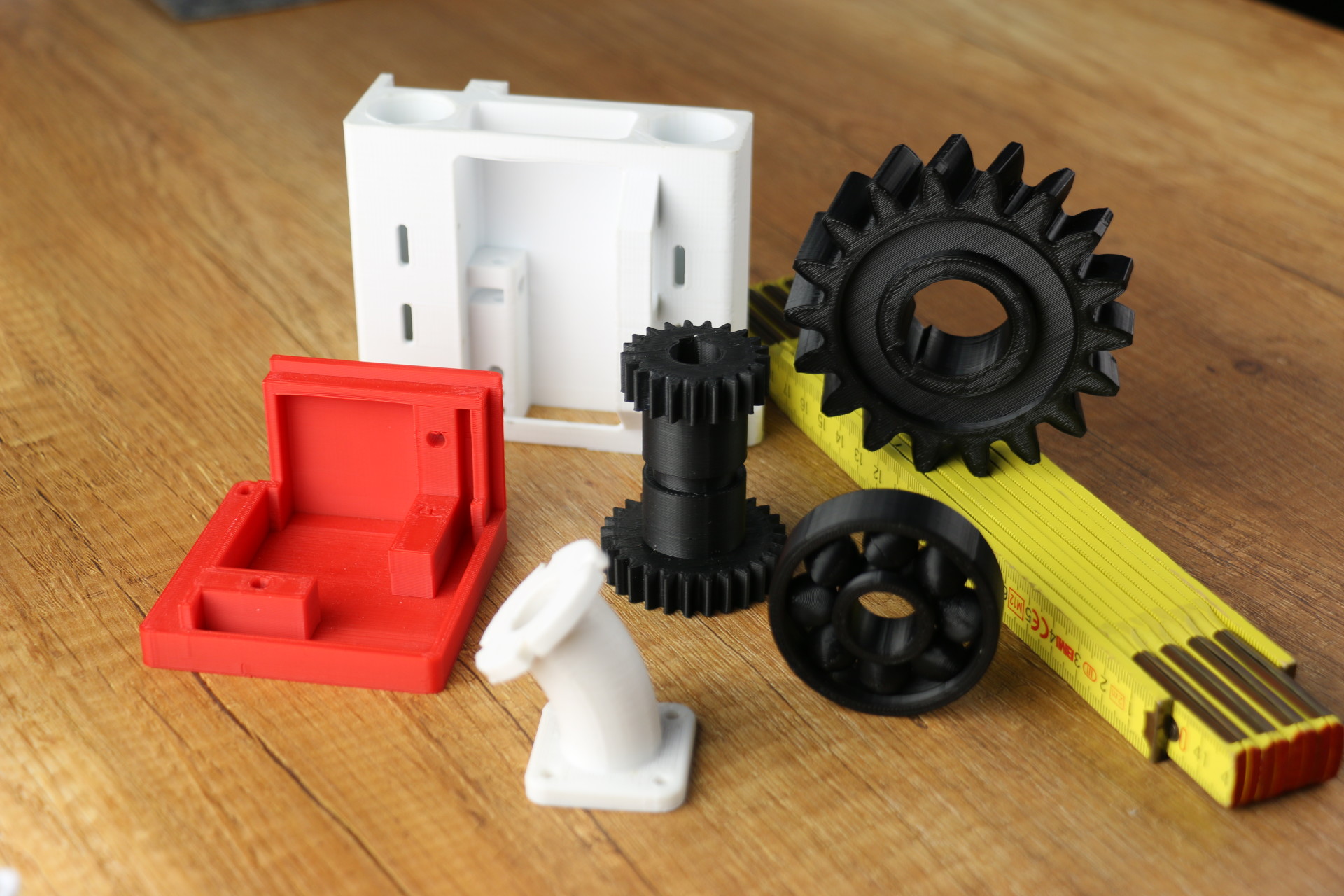

- Build volume of 200 x 180 x 290. This is largish, but nowhere near the size of a BigRep ONE, for example. However, it is just the right size for companies producing book-sized prototypes of all types.

- The build chamber can be heated up to 70C, which is the right temperature to avoid warping on most plastics. Note that the stepper motors are inside the heated chamber, but are water-cooled.

- Print bed heating to 130C also permits use of practically any thermoplastic. The print bed is also ready for use immediately without the need for application of any pretreatment and can handle: ABS, PETG, HIPS, PVA, PLA, TPU, PA12 and PEEK.

- Wide range of layer heights, from 0.05 to 0.60mm. This permits both highly accurate fine prints, but also allowing for very rapid coarse prints where resolution doesn’t matter. The 0.6mm layer is very large and should dramatically speed up prints. Quick-swap tips permit rapid changes.

- An air filter (activated carbon) removes odors generated during printing and even certifies the HT500 for EU product safety for use in offices.

- A color touch screen panel controls operations, including a calibration wizard that walks you through bed leveling steps. It’s not completely automated, but this is a good feature.

- A detector triggers when filament runs out and automatically pauses the machine without human intervention. This feature will certainly pay off by increasing plastic material efficiency.

- A complete 12 piece tool set is included with each HT500.

- Finally, the HT500 has dual print heads, both of which can heat up to a startling 500C! This permits the use of exotic plastics such as PEEK and Polycarbonate.

I think you must agree that these are very powerful specifications for any filament-based 3D printer.

I’m not certain of the current price for the HT500, but I suspect it would be higher than their previous model, which was priced at €5,000 (USD$5,500). More than you’d pay for a hobby machine certainly but definitely less than some other industrial 3D printer options. And with the HT500, you may use lower-cost generic plastic filament, too.

Via Kühling&Kühling