This week’s selection is the incredible 3D printed DIY Sneaker by Georg Simon Ohm.

Germany-based Ohm, also known online as OhmCast, produces a number of interesting videos on his YouTube channel, but one recent caught our eyes.

The video shows in how he was able to build a set of practical wearable sneakers, partly using 3D printing. The sole is 3D printed, while the remaining parts are conventionally made.

As you might imagine, the shoes are perfectly sized for Ohm’s feet. That’s what you can do with 3D printing: customized designs that fit only one person.

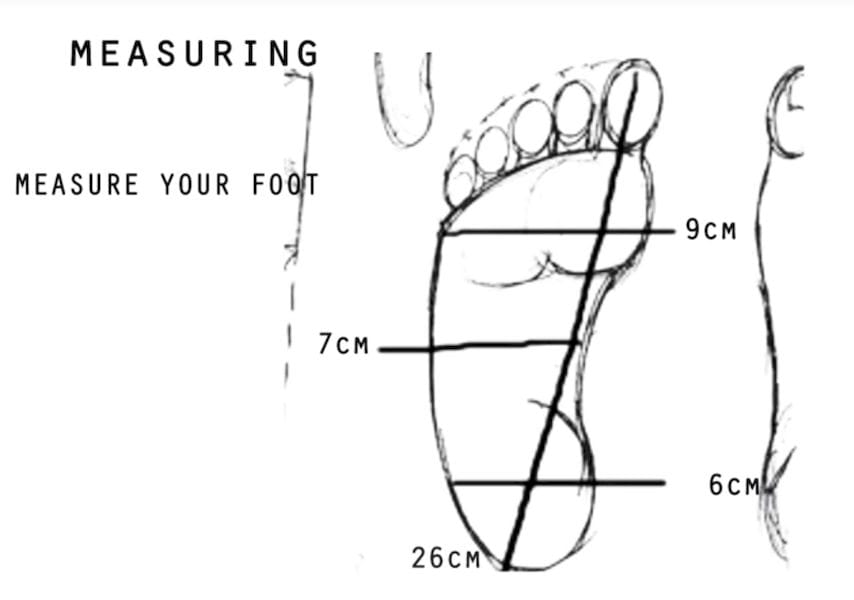

Ohm starts with basic measurements of his feet. I’m particularly interested in which dimensions were used. These measurements are then used to devise the 3D model of the sole.

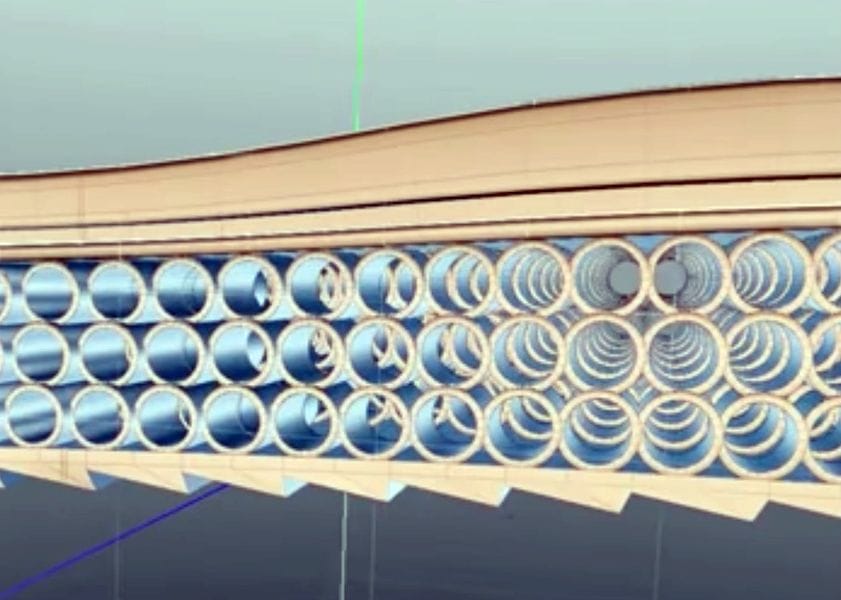

The sole design seems similar to conventionally designed shoes, although it uses a series of cylinders for shock absorption.

This is very reminiscent of Carbon’s work with Adidas on the FUTURECRAFT 4D shoe, but that shoe’s lattice involves varying the strength and flexibility continuously throughout the sole by adapting the lattice in a complex manner. That’s not the case with Ohm’s sole, which seems to be a series of identical cylinders.

Nevertheless, the sole is not something you could easily make with conventional equipment and is best produced on a 3D printer.

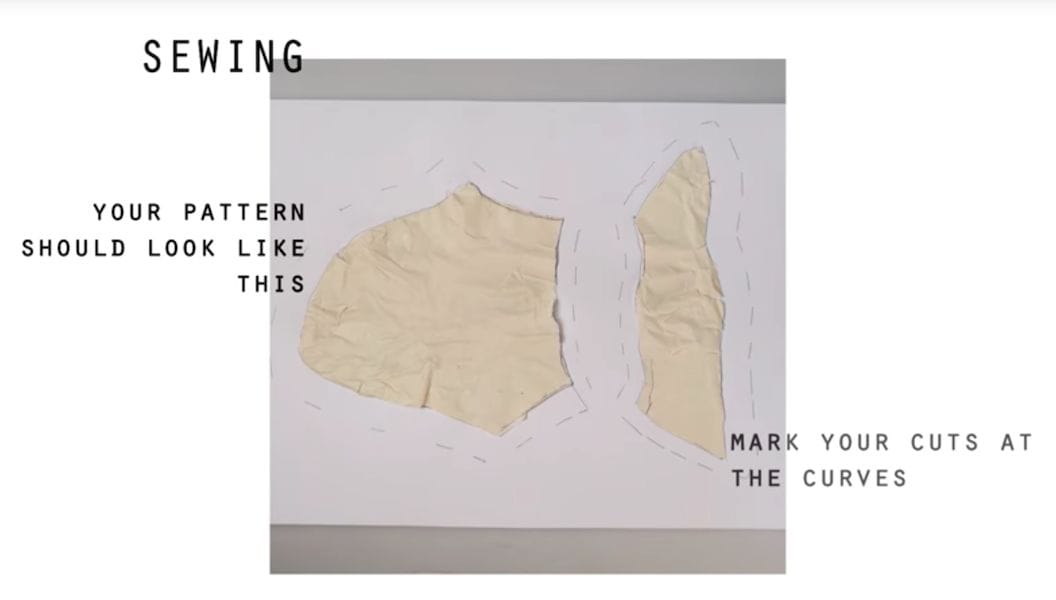

The overall shape of the shoe is somewhat complex, involving a series of curves that match your foot’s shape. Ohm unfortunately does not explain how this is measured and designed, but it would seem you need some 3D modeling skills to produce that part of the design.

Once the design is completed, it’s printed in grade A95 TPU thermoplastic. Ohm had great difficulty printing this, as you’ll see in the video, with many failed print attempts. But finally he discovered the optimum print settings and successfully produced the sole.

Ohm also provides information on how to produce the “upper”, which is cut and sewn neoprene fabric.

The result is a DIY Sneaker you can actually wear in real life.

It’s not clear how durable this shoe might be, but it doesn’t matter: if it wears out, just make another one!

Via YouTube