Students at the Rochester Institute of Technology Statics Lab were challenged to build a truss out of any non-metallic material, with the winning design being the one holding up the most weight.

Students at the Rochester Institute of Technology Statics Lab were challenged to build a truss out of any non-metallic material, with the winning design being the one holding up the most weight.While other students opted for traditional materials such as bamboo or wood, student Kyle Manchester remembered there was a Dimension 3D printer on campus from previous work he’d done. He decided what any of us would do: print the truss components on the Dimension 3D printer.

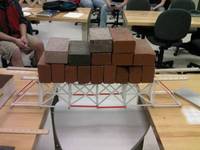

By carefully designing the components to match the predicted static loads, Kyle printed out the dozens of required objects and assembled them into the bridge you see in the image above. You’ll also perhaps notice the more than 40 bricks supported by the not-so-fragile 1.3 pound truss. The truss also held up a team member weighing 190 pounds, meaning it held up 146.15 times its own weight.

Hat tip to Jessica

That is a very cool video! Great idea!

With a 3d printer you could have done a cool truss: http://www.youtube.com/watch?v=s012y1zorX0&playnext=1&list=PL330B99D59764ED12&index=18