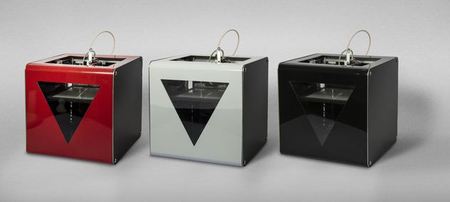

A new Indiegogo project hopes to develop the FABotum, a multidiscipline manufacturing device. Actually, it’s full name is the “FABtotum Multipurpose Desktop Personal Fabricator”.

Wait, what kind of a machine is that? This machine is actually a combination of several manufacturing processes, including 3D printing. The FABotum also includes CNC (cutting) capability and 3D laser scanning, too.

The 3D printer function appears to be comparable to standalone 3D personal printers: up to 0.1mm layer size; prints PLA and ABS plastic filament and has a 210x240x240mm build volume.

The CNC function includes a spindle that holds a bit for milling, and it can apparently be moved along four axes for excellent access. The spindle motor is only 30 Watts, and therefore can cut only very light materials like foam and balsa wood. Engraving on harder materials is possible, however.

The 3D scanning function involves two processes: laser scanning and touch scanning. The laser function provides limited accuracy scans, while the touch mode involves using the highly accurate Z-axis to raise and lower a fine probe to gather height information on a scanned object.

The FABotum is being developed by a team from Italy, who hope to raise USD$50,000 by October. They’re well on the way to achieving that goal. It looks like the target price for a fully assembled FABotum will be USD$1,099, or perhaps higher after their launch.

Interestingly, the FABotum has peculiar licensing terms. The project seems to have intentions of open sourcing as much as possible, yet they have obtained patents on the “FABtotum technologies”. They will permit development of third party “heads” for the moving part of the machine, yet provide “full documentations,drawings and the reproduction of FABtotum is allowed and encouraged under the Creative Commons Attribution-Noncommercial-Sharealike 3.0 Unported Licence.”

We’re not entirely certain what this means.

Regardless, this machine is unique. It combines multiple open source manufacturing technologies into a single, affordable box. We think this is a very challenging project; the software alone will be a complex combination of different approaches. Nevertheless, if they pull it off it could be the beginning of a new product type: personal fabricators.

Via Indiegogo