3D printer manufacturer Formlabs has been tuning up their software – and we think that’s a key strategy for them.

While the company recently upgraded their flagship 3D printer to the Form 1+, they’ve been working on more than just hardware. The new version of PreForm, their slicing and control software, can make the machine more effective.

First, PreForm now permits printing in 0.2mm layers. Wait, you say that’s LESS accurate than before. You’d be correct. The reason they’ve implemented this feature is to permit more rapid printing when resolution is not required. This means the Form 1+’s print speed can compete with other options.

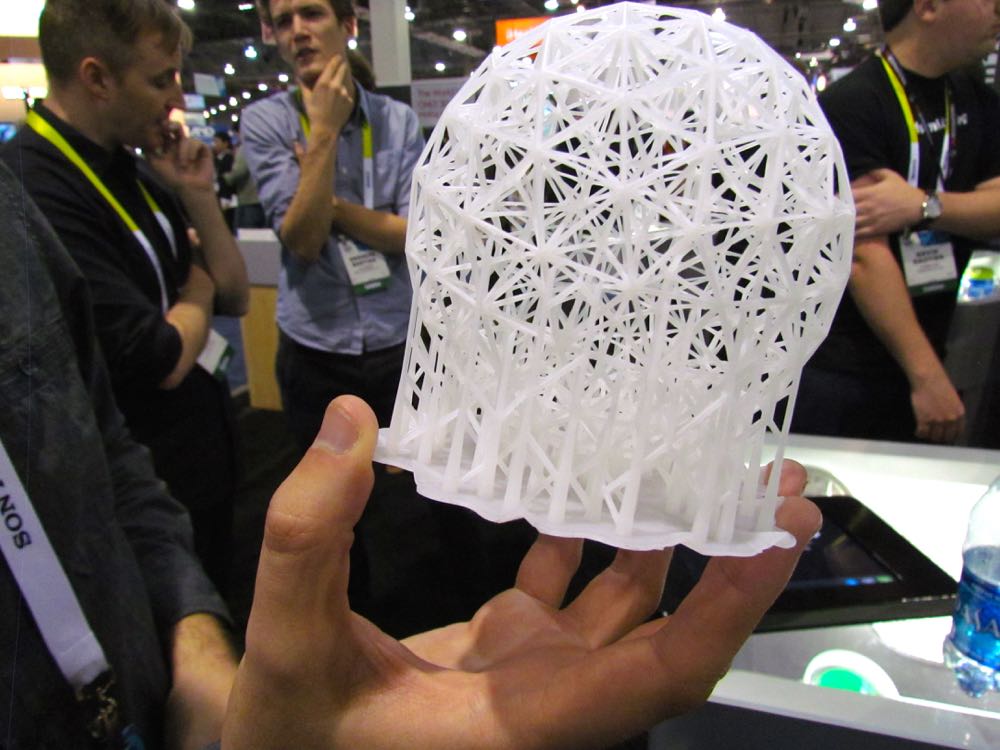

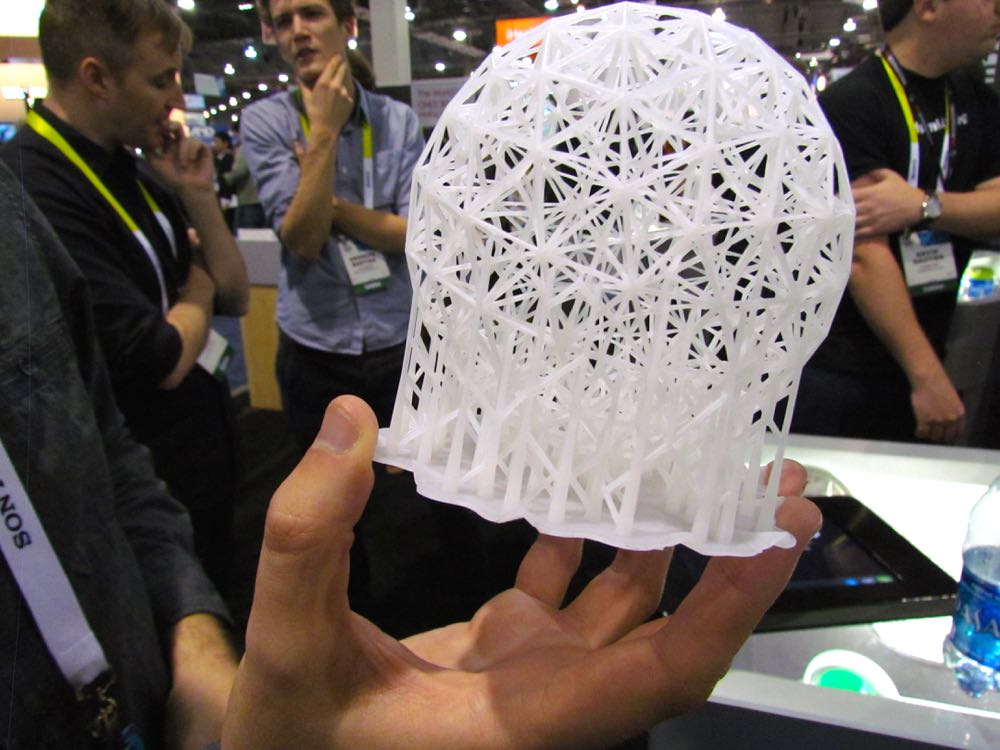

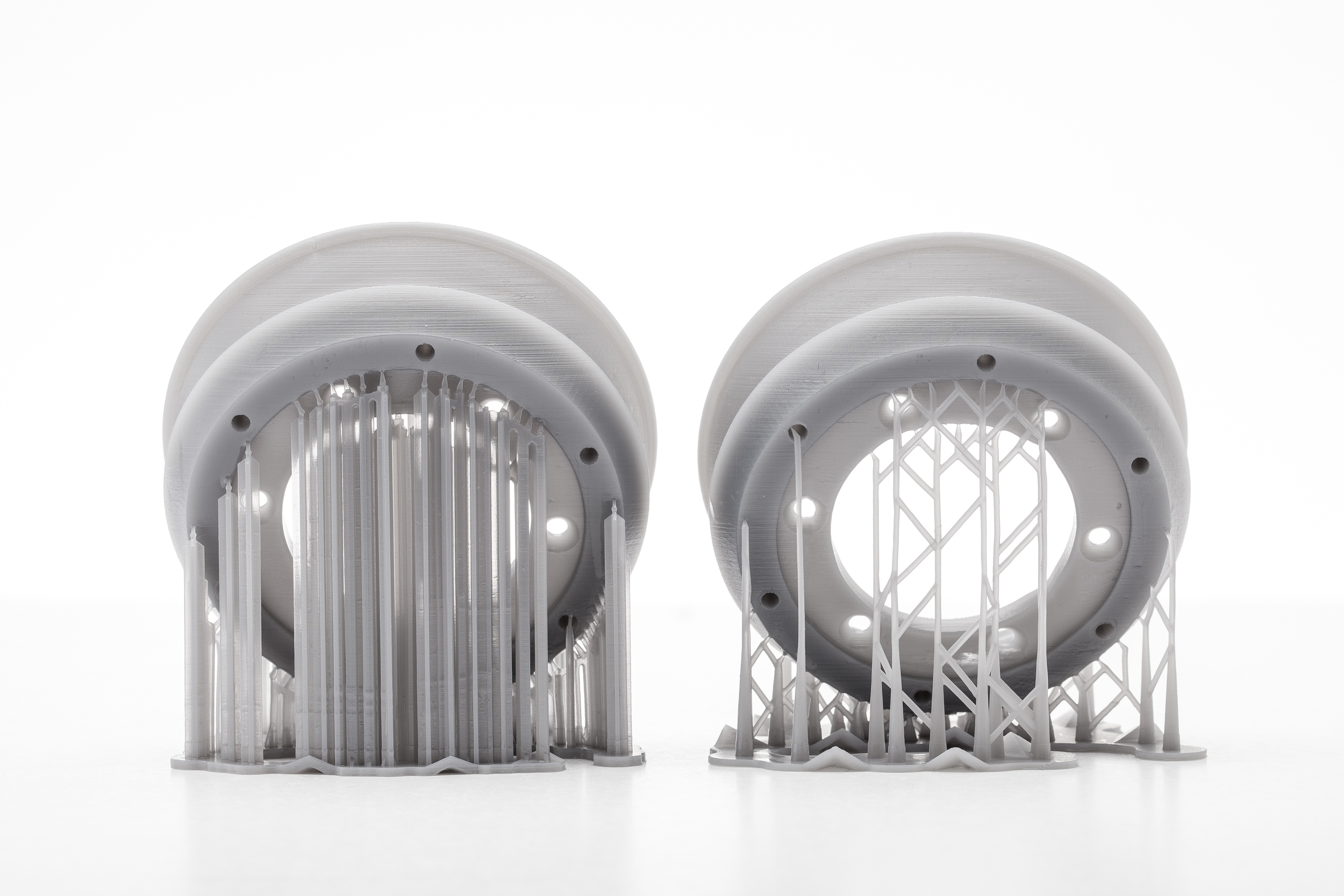

Second, the new PreForm has significantly changed how support structures are generated. The new method involves “tree” supports, which are rapidly gaining popularity among smart slicing software options. This style uses significantly less material (as seen in the image here), takes less time to print and is far less difficult to remove after printing. Even better, the finished print has fewer support contact spots that can detract from surface finish.

But here’s the interesting thing, from our view: A 3D printer is not just a piece of hardware. It’s a combination of hardware and software. Formlabs deeply understands this and has been working very hard to provide software that can drive the hardware in the best ways possible. Other manufacturers, take note: software is very important.

Via Formlabs